Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Machining

- Indexable Cutting Tools

- Indexable Turning

- Indexable Turning Inserts

.....Read More

Frequently Asked Questions

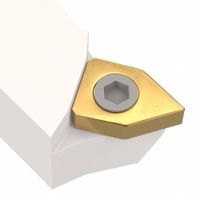

What are indexable turning inserts?

Indexable turning inserts are cutting tools used in machining operations, specifically in turning processes on lathes. These inserts are designed to be mounted on a tool holder and are used to remove material from a rotating workpiece to achieve the desired shape and finish. The term "indexable" refers to the ability to rotate or flip the insert to a new cutting edge once the current edge becomes worn or dull, maximizing the use of the insert and reducing downtime.

Typically made from hard materials like carbide, ceramics, or cermets, indexable inserts are available in various shapes, such as square, triangular, round, and diamond, each suited for different types of cuts and finishes. The inserts are often coated with materials like titanium nitride (TiN) or aluminum oxide (Al2O3) to enhance their wear resistance and performance.

Indexable inserts are preferred in industrial settings due to their cost-effectiveness and efficiency. Instead of replacing the entire tool, only the insert needs to be changed, which is quicker and more economical. This modularity also allows for easy adaptation to different machining tasks by simply swapping inserts.

The inserts are standardized according to ISO and ANSI specifications, ensuring compatibility across different tool holders and machines. They are identified by a series of letters and numbers that denote their shape, size, thickness, cutting edge, and other characteristics.

Overall, indexable turning inserts are essential components in modern machining, offering versatility, precision, and efficiency in metalworking operations.

How do indexable turning inserts work?

Indexable turning inserts are cutting tools used in lathes and turning machines for metalworking. They are designed to be clamped onto a tool holder and can be rotated or indexed to present a fresh cutting edge when one becomes worn. This design eliminates the need for regrinding, reducing downtime and increasing efficiency.

The inserts are typically made from hard materials like carbide, ceramics, or cermets, which provide durability and heat resistance. They come in various shapes, such as square, triangular, or round, each suited for different types of cuts and materials. The geometry of the insert, including its rake angle, clearance angle, and edge preparation, is engineered to optimize cutting performance, chip control, and surface finish.

Indexable inserts are secured in place by a clamping mechanism on the tool holder, which can be a top clamp, screw, or lever. This allows for quick and easy replacement or rotation of the insert without removing the tool holder from the machine, minimizing setup time.

The inserts are often coated with materials like titanium nitride (TiN) or aluminum oxide (Al2O3) to enhance wear resistance and reduce friction. These coatings help extend the life of the insert and improve cutting performance.

In summary, indexable turning inserts are a versatile and efficient solution for metal cutting, offering multiple cutting edges, easy replacement, and adaptability to various machining conditions. They are essential in modern manufacturing for their ability to maintain precision and productivity.

What are the benefits of using indexable turning inserts?

Indexable turning inserts offer several benefits:

1. **Cost Efficiency**: They reduce tooling costs as only the insert needs replacement, not the entire tool. This is more economical over time.

2. **Versatility**: Inserts come in various shapes, sizes, and materials, allowing for a wide range of applications and materials to be machined with the same tool holder.

3. **Reduced Downtime**: Quick and easy replacement of inserts minimizes machine downtime, enhancing productivity.

4. **Consistent Performance**: Inserts provide consistent cutting performance and surface finish due to their precision manufacturing.

5. **Improved Tool Life**: Coatings and advanced materials used in inserts enhance wear resistance and tool life.

6. **Flexibility**: Multiple cutting edges on an insert can be used before it needs replacement, maximizing usage.

7. **Enhanced Productivity**: High-speed machining is possible with indexable inserts, increasing production rates.

8. **Precision**: Inserts are manufactured to tight tolerances, ensuring precise and accurate machining.

9. **Reduced Inventory**: A single tool holder can accommodate various inserts, reducing the need for multiple tools.

10. **Environmental Benefits**: Less material waste is generated as only the insert is discarded, not the entire tool.

11. **Safety**: Quick changeover reduces the risk of injury during tool changes.

12. **Customization**: Inserts can be tailored for specific applications, optimizing performance for particular tasks.

These benefits make indexable turning inserts a preferred choice in modern machining operations.

How do you choose the right indexable turning insert?

1. **Material Compatibility**: Choose an insert material compatible with the workpiece material. Common materials include carbide, ceramic, CBN, and PCD, each suited for different materials like steel, cast iron, or non-ferrous metals.

2. **Insert Shape**: Select the shape based on the type of turning operation. Common shapes include round, square, triangular, and diamond. The shape affects strength and versatility; for example, round inserts are strong and good for heavy cuts, while diamond shapes are versatile for finishing.

3. **Insert Size**: Consider the size based on the depth of cut and machine capability. Larger inserts handle deeper cuts and more aggressive machining, while smaller inserts are suitable for precision work.

4. **Insert Grade**: Choose the grade based on the balance between wear resistance and toughness. Coated grades offer better wear resistance, while uncoated grades may provide better toughness.

5. **Cutting Edge Geometry**: Select the geometry based on the desired surface finish and cutting conditions. Positive rake angles reduce cutting forces and are suitable for softer materials, while negative rake angles are stronger and better for harder materials.

6. **Chipbreaker Design**: Choose a chipbreaker that matches the material and operation to ensure effective chip control, which is crucial for maintaining surface finish and preventing tool damage.

7. **Feed Rate and Speed**: Ensure the insert can handle the required feed rate and cutting speed. Manufacturer guidelines provide optimal parameters for each insert type.

8. **Machine Tool Compatibility**: Ensure the insert fits the tool holder and machine specifications, including the clamping system and tool post.

9. **Cost and Availability**: Consider the cost-effectiveness and availability of the insert, balancing performance with budget constraints.

10. **Manufacturer Recommendations**: Follow manufacturer guidelines and recommendations for specific applications to ensure optimal performance and tool life.

What materials are indexable turning inserts made from?

Indexable turning inserts are primarily made from the following materials:

1. **Carbide**: Comprising tungsten carbide particles bonded with cobalt, carbide inserts are the most common due to their excellent hardness and wear resistance. They are suitable for a wide range of materials and applications.

2. **Cermet**: A composite of ceramic and metallic materials, cermet inserts offer high wear resistance and a smoother finish. They are ideal for finishing operations and provide good resistance to built-up edge formation.

3. **Ceramic**: Made from aluminum oxide or silicon nitride, ceramic inserts are used for high-speed machining of hard materials. They offer excellent heat resistance but are more brittle compared to carbide.

4. **Cubic Boron Nitride (CBN)**: CBN inserts are second only to diamond in hardness and are used for machining hard ferrous materials. They provide excellent wear resistance and thermal stability.

5. **Polycrystalline Diamond (PCD)**: PCD inserts are extremely hard and are used for non-ferrous and abrasive materials like aluminum, copper, and composites. They offer superior surface finish and extended tool life.

6. **High-Speed Steel (HSS)**: Though less common for indexable inserts, HSS is used for its toughness and resistance to chipping, suitable for interrupted cuts and less rigid setups.

Each material is chosen based on the specific requirements of the machining operation, including the workpiece material, cutting speed, and desired surface finish.

How do you maintain and store indexable turning inserts?

To maintain and store indexable turning inserts effectively, follow these guidelines:

1. **Storage Environment**: Keep inserts in a clean, dry, and temperature-controlled environment to prevent corrosion and degradation. Avoid exposure to moisture and extreme temperatures.

2. **Original Packaging**: Store inserts in their original packaging to protect them from physical damage and contamination. The packaging often includes compartments that prevent inserts from touching each other, reducing the risk of chipping.

3. **Labeling**: Clearly label storage containers with insert specifications, such as material, size, and geometry, to facilitate easy identification and retrieval.

4. **Inventory Management**: Implement an inventory management system to track insert usage and stock levels. This helps in maintaining optimal inventory and avoiding overstocking or stockouts.

5. **Handling**: Handle inserts with care to avoid dropping or mishandling, which can cause chipping or breakage. Use gloves to prevent oils and dirt from contaminating the inserts.

6. **Inspection**: Regularly inspect inserts for wear, damage, or defects before use. Discard any inserts that are chipped, cracked, or excessively worn to ensure machining quality and safety.

7. **Tool Life Monitoring**: Keep records of tool life and performance to predict when inserts need replacement. This helps in planning maintenance and reducing downtime.

8. **Cleaning**: Clean inserts before storage if they have been used, removing any residues or debris that could cause corrosion or affect performance.

9. **Segregation**: Store different types of inserts separately to prevent mix-ups and ensure the correct insert is used for specific applications.

10. **Training**: Train personnel on proper handling, storage, and maintenance procedures to ensure consistent practices and prolong the life of the inserts.

What are the common shapes and sizes of indexable turning inserts?

Indexable turning inserts come in various shapes and sizes, each designed for specific applications and cutting conditions. Common shapes include:

1. **Triangle (T)**: Offers three cutting edges per side, suitable for general turning and facing operations.

2. **Square (S)**: Provides four cutting edges, ideal for roughing and finishing operations with strong cutting edges.

3. **Diamond (D, C, V)**:

- **D**: 55-degree diamond shape, used for profiling and finishing.

- **C**: 80-degree diamond shape, versatile for both roughing and finishing.

- **V**: 35-degree diamond shape, used for fine finishing and profiling.

4. **Round (R)**: Offers a strong cutting edge, ideal for heavy roughing and interrupted cuts.

5. **Hexagon (H)**: Less common, used for specialized applications requiring multiple cutting edges.

6. **Pentagon (P)**: Provides five cutting edges, used for specific profiling tasks.

Sizes of inserts are typically defined by their inscribed circle (IC) diameter, thickness, and corner radius. Common IC sizes range from 1/4 inch to 1 inch (6.35 mm to 25.4 mm). Thickness varies to accommodate different cutting depths and tool strength requirements. Corner radii are selected based on the desired surface finish and cutting forces, with smaller radii for fine finishing and larger radii for roughing.

The choice of shape and size depends on factors like the material being machined, the type of operation (roughing, finishing, profiling), machine capabilities, and desired surface finish. Inserts are also available in various grades and coatings to enhance performance and tool life.