Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

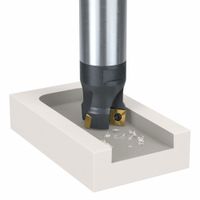

- Machining

- Indexable Cutting Tools

- Indexable Exchangeable Head Milling

- Indexable Mills Milling Cutters

.....Read More

Frequently Asked Questions

What are indexable milling cutters used for?

Indexable milling cutters are used for a variety of machining operations in the manufacturing industry. They are primarily employed for material removal processes, where they efficiently cut and shape metal workpieces. These cutters are equipped with replaceable cutting inserts, which can be indexed or rotated to present a fresh cutting edge, enhancing tool life and reducing downtime.

Key applications include:

1. **Face Milling**: Indexable milling cutters are used to create flat surfaces on a workpiece. They are ideal for removing large amounts of material quickly and efficiently.

2. **Slotting and Pocketing**: These cutters are used to create slots and pockets in components, which are essential for various mechanical assemblies.

3. **Contour Milling**: They are employed in contour milling to produce complex shapes and profiles on a workpiece, often used in the aerospace and automotive industries.

4. **Profile Milling**: Indexable cutters are used to mill profiles and contours, providing precision and accuracy in creating intricate designs.

5. **High-Speed Machining**: Due to their ability to withstand high cutting speeds and feed rates, indexable milling cutters are suitable for high-speed machining applications, improving productivity.

6. **Roughing and Finishing**: They are versatile enough to be used for both roughing operations, where large volumes of material are removed, and finishing operations, where a smooth surface finish is required.

7. **Versatility and Cost-Effectiveness**: The ability to replace only the cutting inserts rather than the entire tool makes indexable milling cutters cost-effective and versatile for various machining tasks.

Overall, indexable milling cutters are essential tools in modern machining, offering flexibility, efficiency, and cost savings in a wide range of industrial applications.

How do indexable inserts work?

Indexable inserts are cutting tools used in machining operations, designed to be replaceable and repositionable. They are typically made from hard materials like carbide, ceramics, or cermets, and are mounted on tool holders. The key feature of indexable inserts is their multiple cutting edges, allowing them to be rotated or flipped to present a fresh edge when one becomes worn, thus extending the tool's life without the need for regrinding.

The inserts are manufactured in standardized shapes and sizes, such as triangles, squares, or rhombuses, and are secured to the tool holder using a clamping mechanism, screws, or wedges. This design allows for quick and easy replacement, minimizing downtime during machining operations.

Indexable inserts work by being precisely positioned in the tool holder to maintain the correct cutting geometry, which is crucial for efficient material removal and surface finish. The insert's geometry, including rake angle, clearance angle, and edge preparation, is engineered to optimize cutting performance for specific materials and applications.

During machining, the insert's cutting edge engages with the workpiece, shearing off material in the form of chips. The insert's material and coating are selected to withstand the high temperatures and forces generated during cutting, providing wear resistance and prolonging tool life.

Overall, indexable inserts enhance productivity by reducing tool change time, improving machining efficiency, and offering flexibility in handling various materials and cutting conditions.

What are the advantages of using indexable mills over solid tools?

Indexable mills offer several advantages over solid tools:

1. **Cost Efficiency**: Indexable mills use replaceable inserts, reducing the need to replace the entire tool when worn. This lowers the overall tooling cost.

2. **Versatility**: They can accommodate various insert geometries and grades, allowing for quick adaptation to different materials and cutting conditions.

3. **Reduced Downtime**: Inserts can be changed quickly without removing the tool from the machine, minimizing downtime and increasing productivity.

4. **Consistent Performance**: Indexable inserts provide consistent cutting performance as they can be rotated or replaced to maintain sharpness.

5. **Material Savings**: Only the insert is discarded when worn, reducing waste compared to replacing entire solid tools.

6. **Improved Heat Management**: Inserts can be designed with advanced coatings and geometries that enhance heat dissipation, improving tool life and performance.

7. **Flexibility in Design**: Indexable mills can be customized with different insert shapes and sizes for specific applications, offering greater flexibility in machining operations.

8. **Reduced Inventory**: A single tool body can be used with various inserts, reducing the need for a large inventory of different solid tools.

9. **Enhanced Tool Life**: The ability to use different insert materials and coatings can extend tool life compared to solid tools.

10. **Ease of Use**: Changing inserts is straightforward, requiring less skill and training compared to regrinding or replacing solid tools.

These advantages make indexable mills a preferred choice in many machining operations, especially in high-volume and high-precision environments.

How do you choose the right indexable insert for a milling operation?

1. **Material Compatibility**: Choose inserts made from materials compatible with the workpiece material. For example, carbide inserts are suitable for steel, while ceramic inserts work well with cast iron.

2. **Insert Geometry**: Select the appropriate geometry based on the operation. Positive rake inserts reduce cutting forces and are ideal for softer materials, while negative rake inserts are more robust for harder materials.

3. **Coating**: Consider coated inserts for enhanced wear resistance and longer tool life. Common coatings include TiN, TiCN, and AlTiN, each offering different benefits like reduced friction or increased heat resistance.

4. **Insert Shape**: Choose the shape based on the desired cutting action and strength. Round inserts are strong and versatile, while square or triangular inserts offer more cutting edges.

5. **Size and Thickness**: Ensure the insert size and thickness match the tool holder and the depth of cut required. Larger inserts can handle heavier cuts, while smaller ones are suitable for precision work.

6. **Cutting Edge Preparation**: Select the edge preparation (sharp, honed, or chamfered) based on the material and finish requirements. Sharp edges are ideal for soft materials, while honed edges are better for hard materials.

7. **Feed and Speed**: Match the insert to the machine's capabilities and the desired feed and speed rates. Some inserts are designed for high-speed operations, while others are better for slower, more controlled cuts.

8. **Application Specifics**: Consider the specific milling operation (e.g., face milling, end milling) and choose inserts designed for that purpose to optimize performance and tool life.

9. **Cost and Availability**: Balance performance with cost-effectiveness and ensure the chosen inserts are readily available for consistent supply.

10. **Manufacturer Recommendations**: Consult manufacturer guidelines and recommendations for the best insert choice for specific applications and materials.

What materials can be machined with indexable milling cutters?

Indexable milling cutters can machine a wide range of materials, including:

1. **Steel**: Both low and high carbon steels, as well as alloy steels, can be effectively machined. This includes tool steels and stainless steels.

2. **Cast Iron**: Gray cast iron, ductile iron, and malleable iron are commonly machined with indexable cutters due to their brittleness and ease of chip formation.

3. **Aluminum**: Both pure aluminum and its alloys are suitable for machining, benefiting from the high-speed capabilities of indexable cutters.

4. **Titanium**: Although challenging due to its toughness and tendency to work harden, titanium can be machined with specialized indexable cutters designed for heat resistance.

5. **Nickel Alloys**: Superalloys like Inconel and Hastelloy, used in high-temperature applications, can be machined with indexable cutters that have appropriate coatings and geometries.

6. **Copper and Brass**: These softer metals are easily machined, with indexable cutters providing good surface finishes and high productivity.

7. **Plastics**: Thermoplastics and thermosetting plastics can be machined, though care must be taken to avoid melting or deforming the material.

8. **Composites**: Fiber-reinforced plastics and other composite materials can be machined, though specialized cutters may be required to handle the abrasive nature of the fibers.

9. **Hard Materials**: With the right inserts, even hardened steels and other hard materials can be machined, though this often requires slower speeds and specialized tooling.

10. **Exotic Materials**: Materials like zirconium and tantalum, used in specialized applications, can also be machined with the appropriate indexable cutters.

The versatility of indexable milling cutters is largely due to the variety of available insert materials and coatings, such as carbide, cermet, ceramic, and polycrystalline diamond (PCD), which can be selected based on the specific material and machining conditions.

How often should indexable inserts be replaced or rotated?

Indexable inserts should be replaced or rotated based on several factors, including the material being machined, the cutting conditions, the type of insert, and the desired surface finish. Generally, inserts should be replaced or rotated when:

1. **Wear Indicators**: Look for signs of wear such as flank wear, crater wear, or chipping. Inserts should be replaced when wear reaches a critical level that affects performance or surface finish.

2. **Surface Finish**: If the surface finish of the workpiece deteriorates, it may indicate that the insert needs replacing or rotating.

3. **Tool Life**: Follow the manufacturer's recommendations for tool life, which can vary based on the insert material and application. Inserts are often designed to last for a specific number of cutting hours or cycles.

4. **Cutting Forces**: Increased cutting forces or vibrations can indicate that the insert is dull or damaged and needs attention.

5. **Material Type**: Harder materials or those with abrasive properties may require more frequent insert changes.

6. **Production Requirements**: In high-precision or high-volume production environments, inserts may need to be replaced more frequently to maintain quality and efficiency.

7. **Cost Considerations**: Balancing the cost of inserts with the cost of downtime and potential damage to the workpiece or machine is crucial. Regular monitoring and timely replacement can prevent costly issues.

8. **Scheduled Maintenance**: Implement a regular maintenance schedule based on historical data and experience with specific operations to optimize insert life and performance.

Ultimately, the frequency of replacement or rotation should be determined by monitoring the specific conditions and performance in your machining operations.

What are the different types of indexable milling cutters and their applications?

Indexable milling cutters come in various types, each designed for specific applications:

1. **Face Mills**: Used for facing operations to produce flat surfaces. They have multiple cutting edges and are ideal for high material removal rates.

2. **End Mills**: Suitable for side milling, slotting, and contouring. They are versatile and can handle a variety of materials and applications.

3. **Shell Mills**: Similar to face mills but designed to be mounted on an arbor. They are used for heavy-duty milling operations.

4. **Slab Mills**: Used for heavy cutting of large and flat surfaces. They are typically used in horizontal milling machines.

5. **Slotting Cutters**: Designed for creating slots and grooves. They are used in applications requiring precision and accuracy.

6. **Ball Nose Cutters**: Used for 3D contouring and complex surface machining. They are ideal for die and mold applications.

7. **Chamfer Mills**: Used to create beveled edges or chamfers on a workpiece. They are essential for deburring and finishing operations.

8. **T-Slot Cutters**: Specifically designed to cut T-slots in machine tables or workpieces. They are used in applications requiring secure workpiece clamping.

9. **Thread Mills**: Used for threading operations. They can produce internal and external threads with high precision.

10. **Hollow Mills**: Used for machining cylindrical surfaces. They are ideal for producing accurate diameters and finishes.

11. **Roughing Mills**: Designed for rapid material removal. They have serrated cutting edges to break up chips and reduce cutting forces.

Each type of indexable milling cutter is chosen based on the material, desired finish, and specific machining requirements, ensuring efficiency and precision in manufacturing processes.