- Home

- Machining

- Indexable Cutting Tools

- Indexable Exchangeable Head Milling

- Indexable Milling Inserts

.....Read More

Ball-Nose Indexable Milling Inserts

Diamond Indexable Milling Inserts

Heptagon Indexable Milling Inserts

Hexagon (H) Indexable Milling Inserts

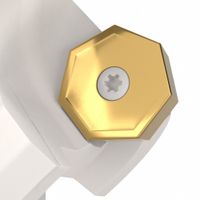

Octagon (O) Indexable Milling Inserts

Parallelogram Indexable Milling Inserts

Pentagon (P) Indexable Milling Inserts

Rectangle (L) Indexable Milling Inserts

Round (R) Indexable Milling Inserts

Specialty & Nonstandard Indexable Milling Inserts

Square (S) Indexable Milling Inserts

Triangle (T) Indexable Milling Inserts

Trigon (W) Indexable Milling Inserts

Frequently Asked Questions

What are indexable milling inserts?

How do I choose the right indexable milling insert for my application?

What are the advantages of using indexable milling inserts over solid tools?

How do I properly install and secure indexable milling inserts?

What materials are indexable milling inserts typically made from?

How do I know when to rotate or replace an indexable milling insert?

What are the different shapes and types of indexable milling inserts available?