Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Electrical

- Motor Controls

- Contactor Motor Starter Replacement Parts Accessories

.....Read More

Frequently Asked Questions

What are the most common replacement parts for contactors and motor starters?

The most common replacement parts for contactors and motor starters include:

1. **Coils**: These are essential for the operation of contactors and motor starters, as they create the magnetic field necessary to close the contacts. Coils can burn out due to overvoltage or excessive heat, making them a frequent replacement part.

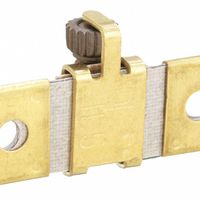

2. **Contacts**: Contacts are prone to wear and tear due to the arcing that occurs when they open and close. Over time, this can lead to pitting or welding, necessitating their replacement to ensure reliable operation.

3. **Auxiliary Contacts**: These are used for additional control functions and can wear out or become damaged, requiring replacement to maintain proper control circuit functionality.

4. **Overload Relays**: These protect motors from overheating by breaking the circuit if the current exceeds a set limit. They can fail due to repeated tripping or mechanical wear, making them a common replacement item.

5. **Arc Chutes**: These components help extinguish the arc formed when contacts open. They can degrade over time due to exposure to high temperatures and need replacement to ensure safe operation.

6. **Enclosures**: While not as frequently replaced as other parts, enclosures can become damaged due to environmental factors or physical impact, requiring replacement to protect internal components.

7. **Terminal Blocks**: These can become loose or corroded, leading to poor electrical connections. Replacing them ensures reliable connectivity.

8. **Springs**: Used to ensure proper contact pressure, springs can lose tension over time, affecting the performance of the contactor or starter.

9. **Mechanical Linkages**: These can wear out or break, affecting the operation of the contactor or starter, and may need replacement to restore functionality.

Regular maintenance and inspection can help identify these parts' wear and tear early, allowing for timely replacement and preventing unexpected equipment failure.

How do auxiliary contacts enhance the functionality of contactors?

Auxiliary contacts enhance the functionality of contactors by providing additional control and signaling capabilities beyond the primary operation of switching power circuits. These contacts are smaller, secondary switches that operate in conjunction with the main contacts of a contactor. Here’s how they enhance functionality:

1. **Control Circuit Integration**: Auxiliary contacts allow for the integration of control circuits, enabling the contactor to interact with other control devices. This facilitates complex control schemes, such as interlocking, sequencing, and feedback loops.

2. **Status Indication**: They provide status feedback by indicating the position of the main contacts (open or closed). This is crucial for monitoring and diagnostics, allowing operators to verify the operational state of the contactor remotely.

3. **Interlocking**: Auxiliary contacts can be used to create electrical interlocks between multiple contactors, preventing simultaneous operation of conflicting circuits. This is essential in applications like reversing motor starters, where it prevents short circuits.

4. **Safety and Protection**: By integrating auxiliary contacts into safety circuits, they can help ensure that certain conditions are met before the main contacts are energized, enhancing operational safety.

5. **Load Shedding and Priority Control**: They enable load shedding and priority control by allowing certain loads to be disconnected or connected based on predefined conditions, optimizing energy usage and system efficiency.

6. **Automation and Logic Control**: In automated systems, auxiliary contacts are used to implement logic control functions, enabling automated responses to changing conditions without manual intervention.

7. **Expansion Capability**: They provide flexibility for future system expansion, allowing additional control functions to be added without replacing the main contactor.

Overall, auxiliary contacts significantly extend the versatility and functionality of contactors, making them integral components in modern electrical control systems.

What is the role of thermal units in motor starters?

Thermal units in motor starters play a critical role in protecting electric motors from overheating and potential damage due to excessive current flow. These units are integral components of thermal overload relays, which are used in conjunction with motor starters to ensure safe and efficient motor operation.

The primary function of thermal units is to detect and respond to overcurrent conditions that can lead to overheating. They achieve this by using a bimetallic strip or a similar temperature-sensitive element that reacts to the heat generated by the current flowing through the motor circuit. As the current increases beyond the motor's rated capacity, the heat generated causes the bimetallic strip to bend or deform. This mechanical movement triggers a mechanism that opens the motor circuit, effectively disconnecting the power supply and preventing further current flow.

By interrupting the circuit, thermal units help prevent damage to the motor windings, insulation, and other components that can occur due to prolonged exposure to high temperatures. This protection is crucial for maintaining the longevity and reliability of the motor, as well as ensuring safety in industrial and commercial applications.

Thermal units are typically adjustable, allowing operators to set the trip point according to the specific requirements of the motor and application. This adjustability ensures that the motor is adequately protected without unnecessary interruptions in operation.

In summary, thermal units in motor starters serve as a safeguard against overheating by detecting overcurrent conditions and interrupting the power supply to the motor. This function is essential for protecting the motor from damage, ensuring operational efficiency, and maintaining safety standards in various applications.

How do delay timers work in motor starter assemblies?

Delay timers in motor starter assemblies are used to control the timing of motor operations, ensuring that motors start, stop, or change states at predetermined intervals. These timers are crucial for applications requiring sequential motor operations, reducing inrush current, or allowing time for mechanical systems to stabilize.

A delay timer typically consists of an electronic or electromechanical device that can be set to delay the activation or deactivation of a motor starter. The timer is integrated into the control circuit of the motor starter assembly. When the control circuit is energized, the timer begins counting down from a preset time. Once the countdown is complete, the timer either closes or opens its contacts, depending on its configuration, to control the motor starter.

There are two main types of delay timers used in motor starter assemblies: on-delay timers and off-delay timers.

1. **On-Delay Timer**: This type of timer delays the activation of the motor starter. When the control signal is applied, the timer waits for the preset time before closing its contacts to start the motor. This is useful for staggering the start of multiple motors to prevent excessive inrush current.

2. **Off-Delay Timer**: This timer delays the deactivation of the motor starter. When the control signal is removed, the timer keeps the motor running for the preset time before opening its contacts to stop the motor. This allows for processes to complete or for systems to stabilize before shutting down.

Delay timers can be adjusted for different time settings, providing flexibility in motor control applications. They enhance the efficiency and safety of motor operations by ensuring that motors operate in a controlled and predictable manner.

What are the benefits of using motor starter enclosures?

Motor starter enclosures offer several benefits:

1. **Protection**: They safeguard the motor starter components from environmental factors such as dust, moisture, and corrosive elements, enhancing the longevity and reliability of the equipment.

2. **Safety**: Enclosures prevent accidental contact with live electrical parts, reducing the risk of electrical shock to personnel. They also contain any electrical arcs or sparks, minimizing fire hazards.

3. **Compliance**: Enclosures help meet regulatory standards and codes, ensuring that installations adhere to safety and operational guidelines set by industry authorities.

4. **Durability**: Made from robust materials like steel, aluminum, or polycarbonate, enclosures provide mechanical protection against impacts, vibrations, and other physical stresses.

5. **Customization**: They can be tailored to specific requirements, including size, material, and additional features like ventilation or cooling systems, to suit various applications and environments.

6. **Organization**: Enclosures facilitate neat and organized wiring and component arrangement, simplifying maintenance and troubleshooting.

7. **Noise Reduction**: By enclosing the motor starter, noise levels can be reduced, contributing to a quieter working environment.

8. **Thermal Management**: Enclosures can be equipped with cooling systems or ventilation to manage heat dissipation, preventing overheating and ensuring optimal performance.

9. **Aesthetic Appeal**: They provide a clean and professional appearance, which is important in commercial and industrial settings.

10. **Versatility**: Suitable for a wide range of applications, from industrial machinery to HVAC systems, enclosures can be used in diverse environments, including hazardous locations with appropriate ratings.

Overall, motor starter enclosures enhance the safety, efficiency, and reliability of motor control systems, making them a crucial component in electrical installations.

How do replacement coils function in contactors?

Replacement coils in contactors function as the electromagnetic component responsible for the operation of the contactor. When electrical current flows through the coil, it generates a magnetic field. This magnetic field is crucial for the contactor's operation, as it attracts and pulls a movable armature or plunger towards the coil. This movement closes the contactor's contacts, allowing electrical current to flow through the main circuit, thus energizing the connected load, such as a motor or lighting system.

The coil is typically designed to operate at a specific voltage and frequency, matching the control circuit's specifications. When the control circuit is energized, the coil receives the voltage, creating the magnetic field necessary for the contactor's operation. Once the control circuit is de-energized, the magnetic field collapses, and a spring mechanism returns the armature to its original position, opening the contacts and interrupting the current flow in the main circuit.

Replacement coils are used when the original coil in a contactor fails or needs to be replaced due to wear, damage, or a change in control voltage requirements. They must be compatible with the contactor's design and specifications to ensure proper operation. Proper installation and connection of the replacement coil are essential to maintain the contactor's functionality and reliability.

What is the purpose of drum and motor switch replacement parts?

The purpose of drum and motor switch replacement parts is to ensure the proper functioning and longevity of appliances and machinery that rely on these components. Drum switches are used to control the direction and operation of electric motors, commonly found in equipment like washing machines, conveyor belts, and industrial machinery. They allow users to start, stop, and reverse the motor's direction, providing essential control over the machine's operation.

Motor switches, on the other hand, are crucial for starting and stopping the motor, protecting it from overload, and ensuring safe operation. They can include features like thermal overload protection, which prevents the motor from overheating and getting damaged. Over time, these switches can wear out due to frequent use, exposure to environmental factors, or electrical faults, leading to malfunction or failure.

Replacing worn or faulty drum and motor switches is vital for maintaining the efficiency and safety of the equipment. A malfunctioning switch can lead to operational issues, such as the inability to start or stop the motor, erratic motor behavior, or even complete equipment failure. This can result in downtime, increased maintenance costs, and potential safety hazards.

By replacing these parts with high-quality, compatible replacements, users can restore the equipment's functionality, improve performance, and extend its lifespan. It also ensures compliance with safety standards and reduces the risk of accidents or damage to other components. Regular maintenance and timely replacement of drum and motor switches are essential practices for optimal equipment performance and reliability.