Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Adhesives Sealants And Tape

- Caulks Sealants Gasket Makers

- Pipe Sealants

.....Read More

Frequently Asked Questions

What is the best pipe sealant for preventing leaks?

The best pipe sealant for preventing leaks depends on the type of pipes and the specific application. For general use, Teflon tape, also known as PTFE tape, is widely recommended for its ease of use and effectiveness in sealing threaded pipe joints. It is suitable for water, air, and gas lines and provides a reliable seal that prevents leaks.

For more demanding applications, such as high-pressure or high-temperature systems, a pipe thread sealant paste, often referred to as pipe dope, is preferred. These pastes are available in various formulations, including those that are resistant to chemicals, heat, and pressure. They provide a durable seal and are ideal for metal pipes.

Anaerobic sealants are another excellent choice for metal pipe connections. These sealants cure in the absence of air and provide a strong, leak-proof bond. They are particularly effective in high-pressure systems and are resistant to vibration and temperature fluctuations.

For plastic pipes, a solvent-based cement is often used. This type of sealant chemically fuses the pipe and fitting together, creating a permanent and leak-proof joint. It is essential to use the correct type of cement for the specific plastic material, such as PVC, CPVC, or ABS.

In summary, the best pipe sealant depends on the pipe material and application conditions. Teflon tape is suitable for general use, pipe dope is ideal for high-pressure and high-temperature applications, anaerobic sealants are excellent for metal pipes, and solvent-based cements are best for plastic pipes. Always ensure compatibility with the pipe material and follow manufacturer recommendations for optimal results.

How do you apply pipe thread sealant?

To apply pipe thread sealant, first ensure the threads are clean and dry. Begin by selecting the appropriate sealant for your application, considering factors like temperature, pressure, and the type of fluid being transported.

1. **Preparation**: Clean the male and female threads using a wire brush or cloth to remove any debris, oil, or old sealant. Ensure the threads are dry to promote better adhesion.

2. **Application**:

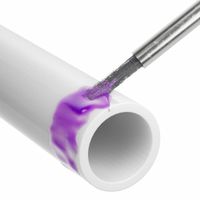

- For liquid sealants, shake the bottle well. Apply a thin, even coat of sealant starting at the second thread from the end of the male pipe. Avoid the first thread to prevent excess sealant from entering the pipe system.

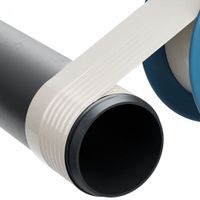

- For tape sealants, wrap the tape around the male threads in the direction of the thread spiral (usually clockwise). Start at the second thread and overlap each wrap by half the width of the tape. Typically, 2-3 wraps are sufficient.

3. **Assembly**: Carefully align the male and female threads and begin to hand-tighten. Ensure the threads engage smoothly to avoid cross-threading.

4. **Tightening**: Use a wrench to tighten the connection further. Be cautious not to over-tighten, as this can damage the threads or the sealant layer. Follow the manufacturer's torque specifications if available.

5. **Curing**: Allow the sealant to cure as per the manufacturer's instructions before pressurizing the system. Curing times can vary based on the sealant type and environmental conditions.

6. **Inspection**: Once cured, inspect the joint for leaks by pressurizing the system and checking for any signs of leakage. If leaks are detected, disassemble, clean, and reapply the sealant.

By following these steps, you ensure a secure and leak-free pipe connection.

Can pipe thread sealant be used on plastic pipes?

Yes, pipe thread sealant can be used on plastic pipes, but it is crucial to choose the right type of sealant specifically designed for plastic materials. Not all pipe thread sealants are suitable for plastic pipes, as some can cause damage or degradation to the plastic material. When selecting a sealant, ensure it is labeled as compatible with plastic or PVC pipes. These sealants are typically non-hardening and non-reactive, preventing any adverse chemical reactions with the plastic.

Using the correct sealant helps ensure a watertight seal, preventing leaks and maintaining the integrity of the piping system. It is important to apply the sealant properly by cleaning the threads of the plastic pipe and applying an even coat of sealant to the male threads before connecting the pipes. Avoid over-tightening, as excessive force can crack or damage plastic threads.

In summary, while pipe thread sealant can be used on plastic pipes, it is essential to select a product specifically formulated for plastic to avoid damage and ensure a proper seal.

What is the difference between pipe thread sealant and plumber's putty?

Pipe thread sealant, also known as pipe dope, is a chemical compound used to seal threaded pipe joints. It prevents leaks by filling the gaps between the threads, ensuring a watertight seal. It is typically applied to the male threads of a pipe before connecting it to a fitting. Pipe thread sealants can be either liquid or paste and often contain Teflon or other lubricants to ease assembly and disassembly. They are used in various plumbing applications, including gas, water, and air lines, and are designed to withstand high pressure and temperature variations.

Plumber's putty, on the other hand, is a pliable, clay-like substance used to create watertight seals around non-threaded plumbing fixtures. It is commonly used to seal the area between a sink and a drain flange or between a faucet and a countertop. Plumber's putty remains soft and flexible, allowing it to be easily molded and shaped. It is not adhesive and is not suitable for high-pressure applications. Instead, it is used where a temporary, flexible seal is needed, and it can be easily removed if necessary.

In summary, the primary difference lies in their applications: pipe thread sealant is used for sealing threaded connections to prevent leaks under pressure, while plumber's putty is used for creating flexible seals around non-threaded fixtures.

How long does pipe thread sealant take to dry?

Pipe thread sealant, often referred to as pipe dope, typically takes about 5 to 15 minutes to become tack-free, meaning it will not stick to your fingers when touched. However, the full cure time, which is when the sealant reaches its maximum strength and effectiveness, can range from 24 to 48 hours. This time frame can vary based on several factors, including the specific product used, ambient temperature, humidity levels, and the materials being joined.

Some pipe thread sealants are designed to be fast-acting and may allow for immediate pressurization of the system, while others may require a longer curing period before the system can be safely pressurized. It's important to consult the manufacturer's instructions for the specific sealant being used to determine the appropriate drying and curing times.

Environmental conditions play a significant role in the drying process. Higher temperatures and lower humidity levels generally accelerate drying and curing, while cooler temperatures and higher humidity can slow it down. Additionally, the type of material being sealed, such as metal or plastic, can also influence the drying time.

For applications where immediate pressurization is necessary, consider using a sealant specifically formulated for quick drying or a thread sealant tape, which does not require drying time. Always ensure that the threads are clean and dry before applying the sealant to achieve the best results and prevent leaks.

In summary, while pipe thread sealant may become tack-free in as little as 5 to 15 minutes, allowing for handling, it is advisable to wait 24 to 48 hours for a full cure before subjecting the joint to full pressure. Always refer to the product's instructions for the most accurate guidance.

Is pipe thread sealant tape better than liquid sealant?

The choice between pipe thread sealant tape and liquid sealant depends on the specific application and requirements.

Pipe thread sealant tape, commonly known as Teflon tape, is easy to use, clean, and provides a quick solution for sealing threaded pipe connections. It is non-messy, requires no curing time, and is ideal for DIY projects or situations where disassembly might be needed in the future. Teflon tape is particularly effective for water and air connections, offering a reliable seal that prevents leaks. However, it may not be suitable for high-pressure or high-temperature applications, as it can degrade under extreme conditions.

Liquid sealants, on the other hand, offer a more robust and durable seal, especially in high-pressure and high-temperature environments. They fill gaps more effectively than tape, providing a stronger bond that is less likely to fail over time. Liquid sealants are versatile and can be used on a variety of materials, including metal and plastic. They often require curing time, which can be a drawback for quick repairs, and can be messy to apply. Once cured, they can be difficult to remove, making disassembly challenging.

In summary, Teflon tape is better for quick, clean, and temporary solutions, especially in low-pressure and low-temperature applications. Liquid sealants are preferable for permanent, high-pressure, and high-temperature applications where a strong, durable seal is necessary. The choice ultimately depends on the specific needs of the project, including the type of fluid being transported, the pressure and temperature conditions, and whether future disassembly is anticipated.

Can pipe sealants be used on gas lines?

Yes, pipe sealants can be used on gas lines, but it is crucial to select the appropriate type specifically designed for gas applications. Pipe sealants, also known as pipe dope or thread sealants, are used to ensure a leak-proof seal on threaded pipe connections. For gas lines, it is essential to use a sealant that is rated for gas service to ensure safety and effectiveness.

When choosing a pipe sealant for gas lines, consider the following:

1. **Compatibility**: Ensure the sealant is compatible with the type of gas being transported, such as natural gas or propane. The product label or technical data sheet should specify its suitability for gas applications.

2. **Temperature and Pressure Ratings**: The sealant should be able to withstand the operating temperature and pressure conditions of the gas line. Check the product specifications to ensure it meets these requirements.

3. **Certification and Standards**: Look for sealants that meet industry standards and certifications, such as those from the American National Standards Institute (ANSI) or Underwriters Laboratories (UL). These certifications indicate that the product has been tested and approved for use in gas applications.

4. **Application Method**: Follow the manufacturer's instructions for application to ensure a proper seal. This typically involves cleaning the threads, applying the sealant evenly, and allowing it to cure as recommended.

5. **Safety Precautions**: Always prioritize safety when working with gas lines. Ensure the gas supply is turned off before applying the sealant, and check for leaks after installation using appropriate methods, such as a gas leak detector or soapy water solution.

By selecting the right pipe sealant and following proper application procedures, you can effectively seal gas line connections and prevent leaks.