Call +(254) 703 030 000 / 751 483 999 / 721 704 777

.....Read More

Frequently Asked Questions

What are the best sharpening supplies for maintaining cutting tools?

Maintaining cutting tools requires a variety of sharpening supplies to keep them in optimal condition. The best choices depend on the type of tool, the desired edge, and personal preference.

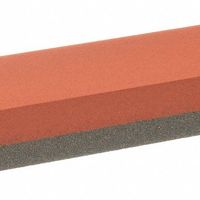

One of the most fundamental tools is a sharpening stone, also known as a whetstone. These come in various grits, from coarse for significant edge repair to very fine for polishing and refining the edge. Popular materials include natural stones (like Arkansas stones), synthetic stones (often made of aluminum oxide or silicon carbide), and diamond stones, which are known for their durability and ability to sharpen even the hardest steels.

Another essential supply is a honing rod or steel, typically used to realign a slightly dulled edge before it needs full sharpening. These are commonly used for kitchen knives. For a more consistent angle, sharpening guides or jigs can be invaluable, especially for beginners. These devices hold the blade at a precise angle to the sharpening surface, ensuring a uniform bevel.

Stropping is the final step for achieving a razor-sharp edge. This involves using a leather or balsa wood strop, often loaded with a fine abrasive compound (like chromium oxide or diamond paste), to remove any burrs and polish the edge to a mirror finish. Other useful supplies include sharpening oils or water (depending on the stone type), angle gauges to check the sharpening angle, and cleaning brushes to keep stones clear of metal filings.

How do I choose the right sharpening stone for my needs?

Choosing the right sharpening stone depends on several factors, including the type of blade you're sharpening, your desired level of sharpness, and your experience. Sharpening stones typically come in various grit levels, ranging from coarse to very fine.

For repairing damaged edges or quickly re-profiling a blade, a coarse grit (around 120-400) is suitable. Medium grits (800-2000) are good for general sharpening and maintaining an edge. For a razor-sharp finish, fine to very fine grits (3000-8000+) are used for honing and polishing.

There are also different types of stones: * **Waterstones:** These require soaking in water before use and produce a muddy slurry that aids in sharpening. They are popular for achieving very fine edges.

* **Oilstones:** These are used with honing oil and are generally more durable than waterstones. They are often preferred for tougher steels.

* **Diamond stones:** These are extremely durable and can sharpen any material, including ceramics and carbide. They don't require water or oil.

* **Ceramic stones:** These can be used dry or with water and offer a consistent abrasive surface.Consider the material of your blade; harder steels may benefit from diamond or ceramic stones, while softer steels might be fine with waterstones or oilstones. Ultimately, the "right" stone is one that meets your specific sharpening needs and preferences.

What is the difference between honing and sharpening?

Honing and sharpening are two distinct processes used to maintain the edge of a blade, such as a knife. While both aim to improve cutting performance, they achieve this in different ways.

Sharpening involves removing metal from the blade to create a new, finer edge. This process uses abrasive materials like sharpening stones (whetstones), diamond plates, or electric sharpeners. The goal is to reshape the bevels of the blade to a sharper angle, effectively creating a new cutting surface. Sharpening is necessary when the blade has become dull, chipped, or has lost its original edge angle due to prolonged use.

Honing, on the other hand, does not remove significant amounts of metal. Instead, it realigns the microscopic edge of the blade, which can become bent or folded over during use. Honing steels or ceramic rods are commonly used for this purpose. These tools are much finer than sharpening abrasives and gently push the misaligned edge back into alignment, restoring its sharpness. Honing is a maintenance step performed more frequently than sharpening, as it helps to keep a sharpened edge keen for longer. It's like combing tangled hair rather than cutting it.

In summary, sharpening creates a new edge by removing material, while honing realigns an existing edge without significant material removal. Sharpening is for dull blades, and honing is for maintaining already sharp blades.

How often should I sharpen my knives and tools?

The frequency of sharpening knives and tools depends largely on their usage. For kitchen knives used daily, a light honing (using a sharpening steel) before each use can maintain the edge, while a full sharpening might be needed every 1-3 months. Tools used less frequently, like garden shears or chisels, might only need sharpening once or twice a year, or when you notice they are no longer cutting efficiently. Heavily used tools or those that encounter hard materials will require more frequent sharpening. Ultimately, the best indicator is the performance of the blade: if it's struggling to cut, it's time to sharpen it. Regular maintenance, even if it's just a quick hone, will extend the life of your blades and make your tasks easier and safer.

What are the benefits of using a sharpening machine?

Using a sharpening machine offers numerous benefits, particularly for tools and blades that see frequent use. Firstly, it ensures consistent and precise sharpening angles, which is difficult to achieve manually. This precision extends the lifespan of your tools by removing only the necessary material. Secondly, sharpening machines are significantly faster than traditional methods, saving valuable time, especially when dealing with multiple tools. They also reduce physical effort, making the sharpening process less strenuous. Thirdly, a properly sharpened tool performs better and more safely; sharp blades cut more efficiently, reducing the risk of slippage and injury. Furthermore, many sharpening machines are versatile, capable of handling a wide range of tools from knives and chisels to drill bits and scissors, making them a cost-effective investment for both professionals and hobbyists. Lastly, they help maintain the value of your tools by keeping them in optimal condition, delaying the need for costly replacements.

How do I properly clean and maintain sharpening stones?

To properly clean and maintain sharpening stones, it's essential to remove metal particles and debris that accumulate during use. For waterstones and oilstones, immediately after sharpening, rinse the stone thoroughly under running water, using a stiff brush (like a toothbrush or scrubbing brush) to dislodge any embedded swarf (metal and abrasive slurry). You can also use a mild soap if the stone is particularly dirty. For oilstones, avoid using water, as it can cause the stone to swell and crack; instead, use honing oil or mineral spirits and a rag to wipe away the residue.

After cleaning, allow waterstones to air dry completely to prevent mold or mildew growth. Store all sharpening stones flat in a dry, cool place to prevent warping or damage. If your stone has developed a concave surface (dish) from repeated use, it's crucial to flatten it. This can be done using a flattening plate, sandpaper on a flat surface (like a piece of glass or a granite slab), or a coarser grit sharpening stone. Flattening ensures consistent contact with the blade and optimal sharpening results. Regular cleaning and flattening will significantly extend the life and effectiveness of your sharpening stones.

Can abrasive sharpening files be used on all types of tools?

Abrasive sharpening files are designed for specific materials and applications, so they cannot be universally used on all types of tools. The effectiveness and safety of using an abrasive file depend on the tool's material, hardness, and intended use. For instance, a file designed for sharpening steel tools might damage or be ineffective on ceramic, carbide, or very soft metal tools. Different abrasive materials (like diamond, ceramic, or various grades of steel) and file cuts are suited for different sharpening needs. Using the wrong type of abrasive file can lead to dulling the tool, damaging its edge, or even causing structural weakness. It's crucial to select an abrasive file that matches the material and required finish of the tool you intend to sharpen.

What is the best technique for hand sharpening knives?

The "best" technique for hand sharpening knives is subjective and depends on factors like the type of knife, the sharpener's skill level, and desired edge. However, a widely effective and recommended method involves using whetstones (also known as water stones or sharpening stones).

Here's a common approach:1. **Preparation:** Soak the whetstone in water (if it's a water stone) until no more bubbles appear. Keep a spray bottle of water nearby to keep the stone wet during sharpening.

2. **Grit Progression:** Start with a coarse grit (e.g., 400-1000 grit) to remove material and establish the bevel. Progress to a medium grit (e.g., 2000-4000 grit) to refine the edge, and finally to a fine grit (e.g., 6000-8000+ grit) for a razor-sharp finish.

3. **Angle Consistency:** Maintaining a consistent angle is crucial. For most kitchen knives, an angle between 15-20 degrees per side is suitable. You can use an angle guide or practice to develop a feel for the correct angle.

4. **Sharpening Stroke:** Place the blade flat on the stone at your chosen angle. Using light to moderate pressure, push the knife along the stone from the heel to the tip, maintaining the angle. Flip the knife and repeat on the other side.

5. **Burr Formation:** Sharpen one side until a "burr" (a tiny wire edge) forms along the opposite edge. You can feel this by gently running your fingertip perpendicular to the edge. Once a burr is present, switch sides and sharpen until the burr transfers to the first side.

6. **Refining the Edge:** As you move to finer grit stones, use lighter pressure and fewer strokes. The goal is to remove the burr and polish the edge.

7. **Stropping (Optional but Recommended):** After the finest stone, use a leather strop with or without a compound to remove any remaining micro-burrs and achieve a mirror polish.Practice is key to mastering hand sharpening. Start with less expensive knives and gradually work your way up. Consistency in angle and pressure will yield the best results.

How do I know when a tool needs to be sharpened?

A tool needs to be sharpened when it no longer performs its intended task efficiently and safely. Here are key indicators: * **Difficulty cutting:** If you have to apply more force than usual to make a cut, or if the tool tears rather than slices, it's a clear sign of a dull edge. For example, a dull knife will slide off a tomato skin instead of cutting cleanly, and dull shears will bend fabric instead of snipping it.

* **Rough or uneven cuts:** A sharp tool leaves a clean, smooth cut. A dull tool will leave ragged edges, splinters, or an uneven finish.

* **Increased effort and fatigue:** Using a dull tool requires more physical effort, leading to quicker fatigue and a higher risk of injury due to slipping or loss of control.

* **Visual inspection:** A truly sharp edge is almost invisible. If you can see light reflecting off the very edge of the blade, it's dull. A sharp edge will appear as a thin, dark line. You can also carefully run your fingernail across the edge (away from your body); a sharp edge will "catch" your nail, while a dull one will slide.

* **Specific tool indicators:** For gardening tools, look for bent or burred edges. For woodworking tools, observe if they are burning the wood or leaving fuzzy surfaces.Regular sharpening not only improves efficiency but also extends the life of your tools and enhances safety.

What safety precautions should I take when using sharpening tools?

When using sharpening tools, it is crucial to prioritize safety to prevent injuries. Always wear appropriate personal protective equipment (PPE), such as safety glasses to protect your eyes from flying debris and sturdy gloves to prevent cuts. Ensure your workspace is well-lit and clear of clutter to avoid accidental slips or missteps.

Before you begin, inspect your sharpening tool for any damage or wear. If using an electric sharpener, ensure the power cord is in good condition and the machine is stable. For manual sharpening, make sure your sharpening stone or steel is securely placed on a non-slip surface.

Always maintain a firm grip on both the sharpening tool and the item being sharpened. Guide the blade or tool smoothly and consistently, applying steady, even pressure. Be mindful of the angle you are using, as an incorrect angle can lead to the blade slipping.

Never rush the sharpening process. Take your time, focus on the task at hand, and avoid distractions. Keep your fingers and other body parts away from the sharpening edge. When not in use, store sharpening tools properly in a safe, secure location, preferably in a case or container, to prevent accidental contact. Regularly clean and maintain your sharpening tools to ensure their effectiveness and safety over time.