Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

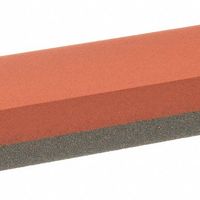

- Abrasives

.....Read More

Frequently Asked Questions

What are abrasives used for?

Abrasives are materials used for rubbing, grinding, or polishing surfaces. They are employed in various applications across industries and daily life. Common uses include shaping and finishing workpieces, removing rust and paint, sharpening tools, and creating textured or smooth finishes. Abrasives are found in sandpaper, grinding wheels, polishing compounds, and even toothpaste. Their effectiveness depends on factors like hardness, grit size, and bond type, allowing for precise control over the material removal process and surface quality.

How do abrasives work?

Abrasives work by removing small amounts of material from a surface through friction. They consist of hard, sharp particles, called abrasive grains, that are bonded together or applied to a backing material. When the abrasive makes contact with a softer surface, the sharp edges of the grains cut, grind, or rub away tiny particles of the workpiece. This process, known as abrasion, can be used for various purposes like shaping, smoothing, polishing, or cleaning surfaces. The effectiveness of an abrasive depends on factors such as the hardness, shape, and size of the abrasive grains, as well as the pressure and speed applied.

What are the different types of abrasives?

Abrasives are materials used to wear away, grind, or polish other substances. They can be classified in various ways, but common distinctions include natural and synthetic abrasives. Natural abrasives like diamond, garnet, and corundum are mined from the earth. Synthetic abrasives, such as silicon carbide, aluminum oxide, boron nitride, and ceramic abrasives, are manufactured for specific properties and applications. Abrasives are also categorized by their form (e.g., bonded abrasives like grinding wheels, coated abrasives like sandpaper, or loose abrasives), their hardness, and their grit size, which determines the fineness of the finish they produce.

What is the difference between natural and synthetic abrasives?

Natural abrasives are minerals found in nature, like diamonds, corundum, and garnet. They are typically less uniform in shape and hardness than synthetic abrasives. Synthetic abrasives, such as silicon carbide and aluminum oxide, are manufactured under controlled conditions. This allows for greater consistency in particle size, shape, and hardness, making them suitable for specialized industrial applications where precision and performance are critical. While natural abrasives are often more cost-effective for general-purpose applications, synthetic abrasives offer superior performance and durability for demanding tasks.

How do I choose the right abrasive for my project?

Choosing the right abrasive depends on your project's material, desired finish, and the tool you're using. For example, harder materials like metal often require aluminum oxide or zirconia alumina abrasives, while softer materials such as wood might use garnet or silicon carbide. Consider the grit size: coarser grits (e.g., 40-80) are for heavy material removal, medium grits (100-180) for general sanding, and finer grits (220+) for finishing. Also, ensure the abrasive type (e.g., sanding disc, belt, or sheet) is compatible with your equipment.

What safety precautions should be taken when using abrasives?

When using abrasives, prioritize safety by wearing appropriate personal protective equipment (PPE), including safety glasses or a face shield, gloves, and dust masks or respirators to protect against airborne particles. Ensure good ventilation in your workspace to minimize dust inhalation. Before use, inspect abrasive tools for damage or cracks and replace them if necessary. Secure your workpiece properly to prevent slippage. Operate tools at recommended speeds and avoid excessive pressure, which can cause breakage or injury. Always follow manufacturer guidelines for the specific abrasive product you are using. After use, clean your tools and workspace, and store abrasives properly.

How are abrasives manufactured?

Abrasives are manufactured through various processes depending on the type and intended use. Natural abrasives like garnet and diamond are mined and then processed by crushing, sorting, and sizing. Synthetic abrasives, such as aluminum oxide, silicon carbide, and boron nitride, are produced in industrial furnaces at high temperatures. These materials undergo crystallization, followed by crushing, milling, and screening to achieve specific grit sizes. Finally, abrasive grains are bonded together using resins, ceramics, or metals to form grinding wheels, sandpaper, or other abrasive tools.

What is the grit size in abrasives?

Grit size in abrasives refers to the average particle size of the abrasive grains used in a product, such as sandpaper, grinding wheels, or blasting media. It's measured by how many abrasive particles can fit into one linear inch. A higher grit number indicates finer abrasive particles, resulting in a smoother finish. Conversely, a lower grit number signifies coarser particles, which are more aggressive and remove material faster. The selection of grit size depends on the desired outcome, whether it's heavy material removal, surface preparation, or achieving a fine polish.

How do I maintain and store abrasives?

To maintain abrasives, regularly inspect them for wear and damage. Clean them as needed to prevent clogging. Proper storage is crucial for longevity and effectiveness. Store abrasives in a dry, temperature-controlled environment to prevent moisture absorption, which can degrade their performance. Keep them organized by grit and type to avoid confusion and make selection easier. Protect them from direct sunlight, extreme temperatures, and physical damage. Discard any abrasives that are cracked, chipped, or severely worn, as they can be unsafe and ineffective.

What are the environmental impacts of using abrasives?

The use of abrasives can lead to several environmental impacts. Manufacturing abrasives often involves mining, which can cause habitat destruction, soil erosion, and water pollution. The production process may release dust and greenhouse gases, contributing to air pollution and climate change. During use, abrasives can generate particulate matter, affecting air quality and human health. Disposal of used abrasives can lead to landfill waste and potential leaching of harmful substances into soil and water. Additionally, some abrasives contain toxic materials that can harm ecosystems. Sustainable practices and recycling can mitigate these impacts, promoting a more environmentally friendly approach.