Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Welding

- Gas Equipment

- Gas Cylinders Accessories

.....Read More

Frequently Asked Questions

What are the safety precautions for handling gas cylinders?

1. **Proper Storage**: Store cylinders upright and secure them with chains or straps to prevent tipping. Keep them in a well-ventilated area away from heat sources and direct sunlight.

2. **Labeling**: Ensure all cylinders are clearly labeled with the type of gas they contain. Do not rely on color coding alone, as it can vary between manufacturers.

3. **Handling**: Use appropriate equipment like cylinder carts for transportation. Never drag, roll, or drop cylinders. Always keep the protective cap on when not in use.

4. **Ventilation**: Ensure adequate ventilation in areas where gas cylinders are used to prevent accumulation of gases, which can lead to asphyxiation or explosion.

5. **Leak Detection**: Regularly check for leaks using soapy water or a gas detector. Never use a flame to check for leaks.

6. **Regulators and Valves**: Use the correct regulator for the specific gas. Open valves slowly and ensure they are fully closed when not in use.

7. **Training**: Ensure all personnel handling gas cylinders are properly trained in their use, storage, and emergency procedures.

8. **Emergency Procedures**: Have clear emergency procedures in place, including evacuation plans and access to safety equipment like fire extinguishers and gas masks.

9. **Separation**: Store flammable gases separately from oxidizers and other incompatible materials to prevent reactions.

10. **Inspection**: Regularly inspect cylinders for damage, corrosion, or leaks. Do not use damaged cylinders.

11. **Temperature Control**: Avoid exposing cylinders to extreme temperatures. Do not store them in areas where temperatures exceed 125°F (52°C).

12. **Personal Protective Equipment (PPE)**: Use appropriate PPE, such as gloves and safety glasses, when handling cylinders.

13. **No Smoking**: Prohibit smoking and open flames near gas cylinders to prevent ignition of flammable gases.

How do you properly store gas cylinders?

To properly store gas cylinders, adhere to the following guidelines:

1. **Location**: Store cylinders in a well-ventilated, dry, and cool area, away from direct sunlight, heat sources, and ignition points. Ensure the storage area is above ground level and not in basements or pits.

2. **Segregation**: Separate full and empty cylinders. Store flammable gases away from oxidizers and other incompatible materials. Maintain a safe distance between different types of gases.

3. **Positioning**: Store cylinders upright and secure them with chains or straps to prevent tipping. Ensure the valve protection caps are in place when not in use.

4. **Labeling**: Clearly label cylinders with their contents and ensure labels are visible. Do not store cylinders with missing or damaged labels.

5. **Access**: Restrict access to authorized personnel only. Ensure the storage area is clearly marked with appropriate safety signs and emergency contact information.

6. **Temperature**: Maintain storage temperatures between -20°C and 50°C. Avoid extreme temperature fluctuations.

7. **Ventilation**: Ensure adequate ventilation to prevent gas accumulation. Install exhaust fans if necessary.

8. **Fire Safety**: Equip the storage area with appropriate fire extinguishers and ensure they are easily accessible. Regularly inspect and maintain fire safety equipment.

9. **Inspection**: Regularly inspect cylinders for leaks, corrosion, or damage. Remove any compromised cylinders from service immediately.

10. **Handling**: Use appropriate equipment, such as cylinder carts, for moving cylinders. Avoid dropping or dragging cylinders.

11. **Regulations**: Comply with local, state, and federal regulations regarding gas cylinder storage and handling.

By following these guidelines, you can ensure the safe and efficient storage of gas cylinders, minimizing risks to personnel and property.

What is the difference between a gas cylinder and a gas canister?

A gas cylinder and a gas canister are both containers used to store gases, but they differ in size, pressure, and application.

A gas cylinder is typically a larger, high-pressure vessel used for storing and transporting industrial gases such as oxygen, nitrogen, argon, or acetylene. These cylinders are made of durable materials like steel or aluminum to withstand high pressures, often exceeding 2000 psi. They are commonly used in industrial, medical, and laboratory settings. Gas cylinders are equipped with valves and regulators to control the release of gas and are often refilled and reused.

On the other hand, a gas canister is generally smaller and used for lower-pressure applications. Canisters are often made of lightweight materials and are designed for portability. They are commonly used for camping stoves, portable heaters, or small torches. Gas canisters typically contain gases like butane or propane and are often disposable or designed for single use. They operate at lower pressures compared to gas cylinders and are not usually refilled.

In summary, the primary differences lie in their size, pressure capacity, material, and intended use. Gas cylinders are larger, high-pressure, and reusable, suitable for industrial and professional applications. Gas canisters are smaller, lower-pressure, and often disposable, ideal for portable and recreational use.

How do you check the gas level in a cylinder?

To check the gas level in a cylinder, follow these steps:

1. **Weighing Method**:

- Use a scale to weigh the cylinder.

- Subtract the tare weight (empty weight) of the cylinder, which is usually stamped on the cylinder itself, from the total weight.

- The difference is the weight of the gas remaining.

2. **Hot Water Method**:

- Pour hot water down the side of the cylinder.

- Wait a few seconds and then feel the cylinder with your hand.

- The area where the temperature changes from warm to cool indicates the gas level.

3. **Gas Level Indicator Strips**:

- Attach a magnetic or adhesive gas level indicator strip to the side of the cylinder.

- These strips change color based on the temperature difference, showing the gas level.

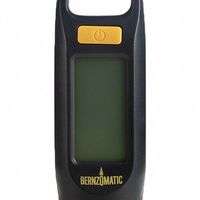

4. **Ultrasonic Gas Level Checker**:

- Use an ultrasonic device designed to measure the gas level.

- Place the device at the bottom of the cylinder and move it upwards until it indicates the gas level.

5. **Float Gauge**:

- Some cylinders come with a built-in float gauge that shows the gas level.

- Check the gauge for an approximate reading of the remaining gas.

6. **Pressure Gauge**:

- For cylinders with a pressure gauge, check the pressure reading.

- Note that this method is more effective for non-liquefied gases, as pressure remains constant for liquefied gases until they are nearly empty.

7. **Smart Gas Meters**:

- Use a smart gas meter that connects to an app or display to show the gas level in real-time.

Always ensure safety by checking for leaks and handling cylinders with care.

What are the common sizes of gas cylinders?

Gas cylinders come in various sizes, typically measured by their water capacity or the amount of gas they can hold. Common sizes include:

1. **Small Cylinders**:

- **1 lb (0.45 kg)**: Often used for portable camping stoves and small appliances.

- **5 lb (2.27 kg)**: Suitable for small grills and portable heaters.

2. **Medium Cylinders**:

- **10 lb (4.54 kg)**: Used for medium-sized grills and heaters.

- **20 lb (9.07 kg)**: The most common size for home barbecues and patio heaters.

3. **Large Cylinders**:

- **30 lb (13.6 kg)**: Used for larger grills and commercial applications.

- **40 lb (18.14 kg)**: Suitable for industrial uses and larger appliances.

4. **Industrial Cylinders**:

- **50 lb (22.68 kg)**: Common in industrial settings for welding and large-scale heating.

- **100 lb (45.36 kg)**: Used for commercial and industrial purposes, such as large heaters and generators.

5. **Specialty Cylinders**:

- **420 lb (190.5 kg)**: Often used in residential and commercial settings for heating and cooking.

- **1000 lb (453.6 kg) and above**: Typically used in industrial applications and bulk storage.

These sizes can vary slightly depending on the country and manufacturer. The choice of cylinder size depends on the specific application, frequency of use, and portability requirements.

How do you transport gas cylinders safely?

To transport gas cylinders safely, follow these guidelines:

1. **Inspection**: Check cylinders for leaks, damage, or expired certification. Ensure valves are closed and caps are securely in place.

2. **Vehicle Selection**: Use a well-ventilated vehicle, preferably open or with a gas-tight partition between the driver and the load.

3. **Securing Cylinders**: Secure cylinders upright using straps or chains to prevent movement. Ensure they are not stacked or placed horizontally.

4. **Loading and Unloading**: Use proper lifting techniques or equipment to avoid dropping cylinders. Handle with care to prevent impact or damage.

5. **Ventilation**: Ensure adequate ventilation to prevent gas accumulation. Avoid transporting in enclosed spaces without proper airflow.

6. **Separation**: Keep flammable gases away from oxidizers and other incompatible materials. Maintain safe distances as per regulations.

7. **Signage**: Display appropriate hazard labels and placards on the vehicle to indicate the presence of gas cylinders.

8. **Temperature Control**: Avoid exposure to extreme temperatures. Do not leave cylinders in direct sunlight or in hot vehicles.

9. **Emergency Preparedness**: Carry a fire extinguisher and have an emergency plan in place. Know the emergency contact numbers and procedures.

10. **Regulatory Compliance**: Adhere to local, state, and federal regulations regarding the transportation of hazardous materials.

11. **Driver Training**: Ensure drivers are trained in handling hazardous materials and aware of the risks and safety procedures.

12. **Documentation**: Carry necessary documentation, including safety data sheets and transport permits, if required.

By following these steps, you can ensure the safe transportation of gas cylinders, minimizing risks to people, property, and the environment.

What should you do if a gas cylinder is leaking?

If a gas cylinder is leaking, follow these steps:

1. **Do Not Panic**: Stay calm to think clearly and act quickly.

2. **Avoid Flames and Sparks**: Do not light matches, lighters, or turn on electrical switches, as they can ignite the gas.

3. **Ventilate the Area**: Open all windows and doors to allow the gas to disperse. This reduces the concentration of gas in the air.

4. **Do Not Use Electrical Appliances**: Avoid using any electrical devices, including phones, as they can create sparks.

5. **Evacuate the Area**: If the leak is significant, evacuate the premises immediately. Ensure everyone, including pets, leaves the area.

6. **Turn Off the Gas Supply**: If safe to do so, turn off the gas supply at the cylinder valve. Turn the valve clockwise to close it.

7. **Do Not Attempt Repairs**: Do not try to fix the leak yourself. Leave it to professionals.

8. **Call Emergency Services**: Once you are at a safe distance, call the fire department or emergency services for assistance.

9. **Notify the Gas Supplier**: Inform your gas supplier about the leak so they can take appropriate action.

10. **Do Not Re-enter Premises**: Do not go back inside until it is declared safe by the authorities.

11. **Seek Medical Attention if Necessary**: If anyone has inhaled gas and feels unwell, seek medical help immediately.

12. **Follow Up**: After the situation is resolved, have the cylinder and gas system inspected by a professional to prevent future leaks.

By following these steps, you can minimize the risk of fire, explosion, and health hazards associated with a gas cylinder leak.