Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Welding

- Arc Welding

- Tig Welding

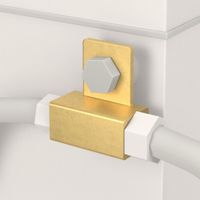

- Tig Power Cables Connectors

.....Read More

Frequently Asked Questions

What is the purpose of TIG power cables?

TIG power cables are used in Tungsten Inert Gas (TIG) welding, a process that employs a non-consumable tungsten electrode to produce the weld. The primary purpose of TIG power cables is to conduct electrical current from the welding power source to the welding torch, enabling the arc necessary for welding. These cables are designed to handle high currents and are insulated to ensure safety and efficiency during the welding process.

TIG power cables are crucial for maintaining a stable arc, which is essential for producing high-quality welds. They must be flexible to allow the welder to maneuver the torch easily, especially in complex or confined spaces. The cables are typically made of copper or aluminum, materials known for their excellent conductivity, which minimizes energy loss and ensures consistent power delivery.

In addition to conducting electricity, TIG power cables often incorporate a gas line that delivers inert gas, such as argon or helium, to the weld area. This gas shields the weld from atmospheric contamination, preventing oxidation and ensuring a clean, strong weld. Some TIG power cables also include a water line for cooling the torch, which is necessary when welding at high amperages to prevent overheating.

Overall, TIG power cables are integral to the TIG welding process, providing the necessary electrical and gas connections to facilitate precise and high-quality welding.

How do you connect a TIG torch to a welder?

1. **Turn Off Power**: Ensure the welder is turned off and unplugged from the power source to prevent any electrical hazards.

2. **Identify Connections**: Locate the connections on both the TIG torch and the welder. Typically, a TIG torch has three main connections: the power cable, the gas hose, and the control switch (if applicable).

3. **Connect Power Cable**: Attach the power cable from the TIG torch to the welder's output terminal. This is usually a large connector, often a DINSE connector, which should be securely fastened to ensure a stable electrical connection.

4. **Connect Gas Hose**: Connect the gas hose from the TIG torch to the gas outlet on the welder or directly to the gas cylinder regulator. Ensure the connection is tight to prevent gas leaks. Use a wrench if necessary to secure the fitting.

5. **Connect Control Switch**: If the TIG torch has a control switch or foot pedal, connect it to the appropriate control socket on the welder. This allows you to control the welding current and arc start/stop functions.

6. **Check Connections**: Double-check all connections to ensure they are secure and properly attached. Loose connections can lead to poor performance or safety hazards.

7. **Set Up Gas Flow**: Open the gas cylinder valve and adjust the flow rate using the regulator to the recommended setting for your welding application.

8. **Power On**: Plug in and turn on the welder. Test the setup by initiating a test arc to ensure everything is functioning correctly.

9. **Safety Check**: Ensure all safety equipment is in place, including gloves, helmet, and protective clothing, before starting the welding process.

What are the different types of TIG torch connectors?

The different types of TIG torch connectors include:

1. **DINSE Connectors**: These are the most common type of connectors used in TIG welding. They come in various sizes, such as 35-50 and 50-70, which refer to the cable size they accommodate. DINSE connectors are known for their secure fit and ease of use.

2. **Lug Connectors**: These are simple connectors that use a bolt and nut to secure the cable to the torch. They are less common in modern setups but are still used in some applications due to their simplicity and reliability.

3. **Twist Lock Connectors**: These connectors use a twisting motion to lock the torch cable into place. They provide a secure connection and are easy to connect and disconnect, making them popular in many welding environments.

4. **Quick Connectors**: These are designed for fast and easy connection and disconnection of the torch. They are often used in situations where torches need to be changed frequently or quickly.

5. **International Connectors**: These are used in some European and international welding machines. They are similar to DINSE connectors but may have different sizing or threading standards.

6. **Water-Cooled Connectors**: For water-cooled TIG torches, connectors are designed to accommodate both the electrical connection and the water lines. These connectors ensure that the torch remains cool during operation.

7. **Gas-Cooled Connectors**: These are used with air-cooled TIG torches and typically include a connection for the shielding gas line along with the electrical connection.

Each type of connector is designed to meet specific needs and preferences in TIG welding, and the choice often depends on the equipment and application requirements.

How do you choose the right TIG power cable?

To choose the right TIG power cable, consider the following factors:

1. **Amperage Rating**: Ensure the cable can handle the maximum amperage of your TIG welder. Check the welder's specifications and select a cable with an appropriate amperage rating to prevent overheating.

2. **Cable Length**: Determine the distance between the power source and the work area. Longer cables may require a larger gauge to minimize voltage drop. Choose a length that provides flexibility without excessive slack.

3. **Cable Gauge**: The gauge affects the cable's current-carrying capacity. A lower gauge number indicates a thicker cable, which can handle more current. Match the gauge to the welder's amperage requirements and cable length.

4. **Insulation Material**: Select a cable with durable insulation to withstand the welding environment. Common materials include rubber and PVC, with rubber offering better flexibility and heat resistance.

5. **Connector Type**: Ensure compatibility with your TIG welder's connectors. Common types include DINSE and Tweco. Verify the connector size and type to ensure a secure fit.

6. **Flexibility**: Choose a cable that remains flexible in your working conditions, especially in colder environments. A flexible cable is easier to maneuver and reduces strain on the welder.

7. **Durability**: Consider the cable's resistance to abrasion, chemicals, and heat. A durable cable will have a longer lifespan and require less frequent replacement.

8. **Brand and Quality**: Opt for reputable brands known for quality and reliability. High-quality cables may have a higher upfront cost but offer better performance and longevity.

By evaluating these factors, you can select a TIG power cable that meets your specific welding needs and ensures safe, efficient operation.

What is the standard length for TIG power cables?

The standard length for TIG (Tungsten Inert Gas) welding power cables typically ranges from 12 to 25 feet. This length is generally sufficient to provide the welder with enough flexibility and mobility to work comfortably around the welding area. However, the specific length can vary based on the manufacturer's specifications and the particular requirements of the welding setup. Some setups may require longer cables, especially in industrial or large-scale applications where the power source is located further from the welding site. It's important to choose a cable length that minimizes resistance and voltage drop while ensuring safety and efficiency in the welding process.

Can TIG power cables be repaired if damaged?

Yes, TIG power cables can be repaired if damaged, but the process requires careful attention to detail and safety precautions. The repairability depends on the extent and type of damage. For minor issues like superficial cuts or abrasions, insulating tape or heat-shrink tubing can be used to cover the exposed areas, ensuring the cable's insulation is restored.

For more significant damage, such as broken conductors or severe insulation breaches, a more involved repair is necessary. This typically involves cutting out the damaged section and splicing the cable back together. The splicing process includes stripping the insulation from the ends of the cable, reconnecting the conductors using appropriate connectors or soldering, and then insulating the joint with heat-shrink tubing or electrical tape to ensure safety and functionality.

It's crucial to ensure that the repaired section maintains the cable's original electrical and mechanical properties. This means using materials that match the cable's specifications and ensuring that the repair is robust enough to withstand the operational environment.

However, it's important to note that repairing power cables, especially those used in TIG welding, should be done by a qualified professional. Improper repairs can lead to safety hazards, including electrical shocks, short circuits, or even fires. In some cases, if the damage is extensive or the cable is critical to operations, replacing the cable might be a more reliable and safer option.

Always ensure that the power source is disconnected before attempting any repairs, and follow all relevant safety guidelines and standards.

What materials are used in TIG power cables?

TIG (Tungsten Inert Gas) welding power cables are designed to carry the electrical current necessary for the welding process. The materials used in these cables are selected for their electrical conductivity, flexibility, durability, and resistance to heat and abrasion. Here are the primary materials used:

1. **Copper Conductors**: Copper is the most common material used for the conductors in TIG power cables due to its excellent electrical conductivity. It allows efficient transmission of the welding current with minimal resistance and heat generation.

2. **Insulation**: The insulation material is crucial for protecting the conductor and ensuring safety. Common insulation materials include:

- **EPDM (Ethylene Propylene Diene Monomer)**: Known for its excellent heat, ozone, and weather resistance, EPDM is flexible and durable, making it ideal for welding environments.

- **Neoprene**: Offers good resistance to oil, chemicals, and abrasion, providing additional protection in harsh conditions.

3. **Jacket**: The outer jacket of the cable provides mechanical protection and additional insulation. Materials used for the jacket include:

- **PVC (Polyvinyl Chloride)**: Offers good flexibility and resistance to abrasion and chemicals.

- **Rubber**: Provides excellent flexibility and durability, suitable for rugged environments.

4. **Reinforcement**: Some cables may include reinforcement layers to enhance strength and durability. This can be achieved through braided or woven materials, often made from synthetic fibers like nylon or polyester.

5. **Connectors and Terminals**: These are typically made from brass or copper alloys to ensure good electrical conductivity and secure connections.

These materials collectively ensure that TIG power cables can withstand the demanding conditions of welding environments while providing reliable performance and safety.