- Home

- Tools

- Power Tools

- Plumbing Power Tools

- Pipe Connection Cutting Power Tools

.....Read More

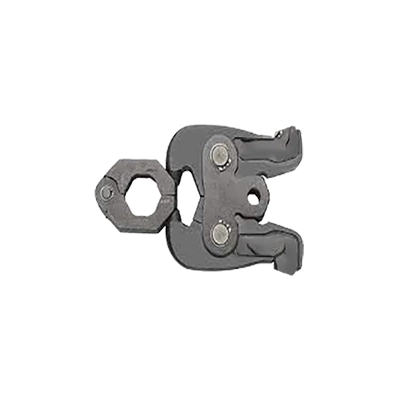

Actuators for Press Fitting Tools

Cordless PEX Expansion Tools

Cordless Pipe & Tubing Cutters

Cutters & Power Adapters for Press Fitting Tools

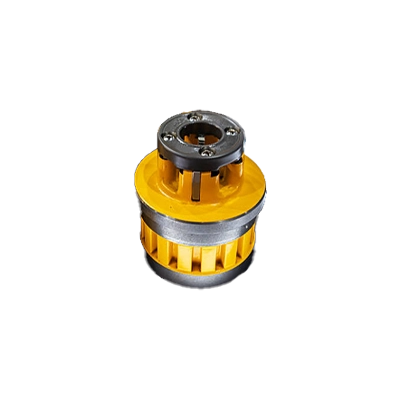

Die Heads for Manual & Handheld Power Pipe Threaders

Die Heads for Pipe Threading Machines

Handheld Power Pipe Threaders

Jaw & Ring Sets for Press Fitting Tools

Jaws & Rings for Press Fitting Tools

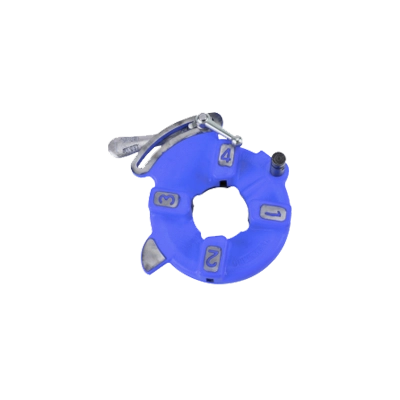

PEX Expansion Heads & Grease

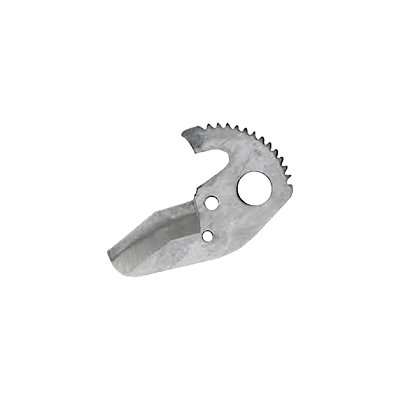

Pipe Cutting Accessories & Replacement Parts

Pipe Reamer Drill Attachments

Pipe Threading Accessories

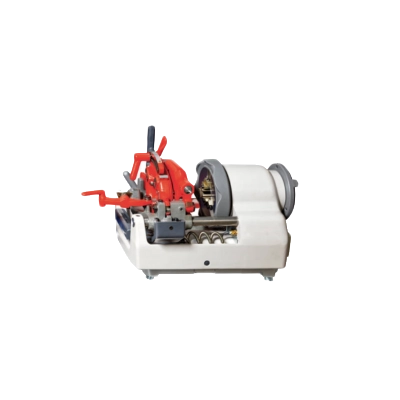

Pipe Threading Machines

Pipe Threading Replacement Parts

Pipe & Tube Cutting Machines

Press Fitting Tools

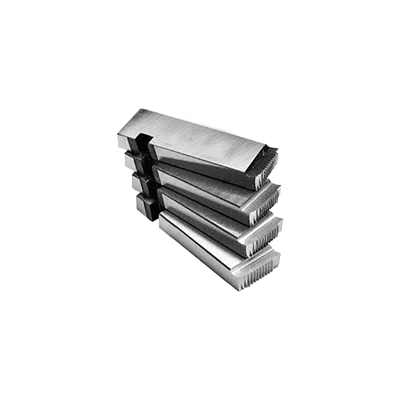

Replacement Dies for Pipe Threading

Replacement Parts for Roll Groovers

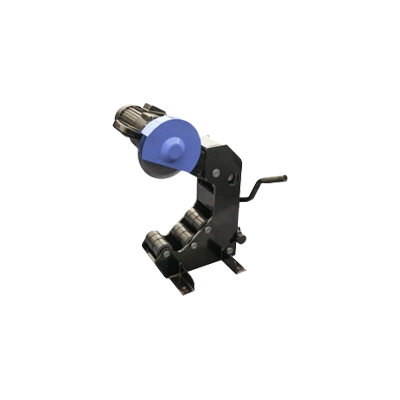

Roll Groovers

Roll Sets & Tool Boxes for Roll Groovers

Frequently Asked Questions

What are the best tools for cutting and preparing pipes for installation?

How do pipe reamer drill attachments work for removing broken plastic pipes?

What is the process for using pipe threading power tools to cut or repair threads?

How do press fitting tools differ from traditional welding or brazing methods?

What are the advantages of using pipe grooving tools for pipe installation?

How do you properly use pipe cutting tools to ensure a clean cut?

What is the procedure for using PEX expanders on PEX type A tubing?