Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Tools

- Power Tools

- Drills Drivers

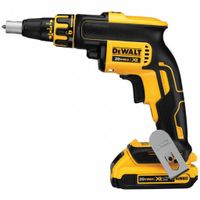

- Screw Guns

.....Read More

Frequently Asked Questions

What is the purpose of an adjustable nose on a screw gun?

The purpose of an adjustable nose on a screw gun is to control the depth to which screws are driven into materials. This feature is crucial for ensuring consistent and precise fastening, which is particularly important in applications like drywall installation, decking, and other construction tasks where uniformity is key.

The adjustable nose allows the user to set a specific depth, preventing screws from being driven too deep, which can damage the material or compromise structural integrity. Conversely, it also ensures that screws are not left protruding, which can lead to an uneven surface or a weak hold. By adjusting the nose, users can accommodate different screw lengths and material thicknesses, enhancing the versatility of the screw gun.

Additionally, the adjustable nose helps in maintaining a smooth workflow by reducing the need for manual adjustments or corrections after screws are driven. This feature contributes to increased efficiency and productivity on job sites, as it minimizes the time spent on rework and ensures a professional finish.

Overall, the adjustable nose on a screw gun is a critical component for achieving precision, consistency, and efficiency in fastening tasks.

How does the clutch mechanism work in a screw gun?

A screw gun's clutch mechanism is designed to control the torque applied to a screw, preventing overdriving or stripping. Here's how it works:

1. **Torque Setting**: The clutch mechanism is adjustable, allowing the user to set the desired torque level. This is typically done by rotating a collar or dial on the tool, which corresponds to different torque settings.

2. **Clutch Components**: The clutch consists of a series of interlocking plates or balls and springs. These components are situated between the motor and the chuck (the part that holds the screw bit).

3. **Engagement**: When the screw gun is activated, the motor drives the clutch mechanism. At low resistance, the clutch plates or balls remain engaged, allowing the full torque of the motor to be transferred to the screw bit.

4. **Disengagement**: As the screw encounters resistance (e.g., when it is fully driven into the material), the torque required to turn the screw increases. Once the resistance exceeds the pre-set torque level, the clutch plates or balls slip or disengage. This slipping action prevents further torque from being applied to the screw.

5. **Feedback**: The user often feels or hears a clicking or ratcheting sound when the clutch disengages, indicating that the screw is fully driven or the set torque limit is reached.

6. **Protection**: This mechanism protects both the screw and the material from damage and ensures consistent screw depth, which is crucial for tasks requiring precision.

By adjusting the clutch, users can tailor the screw gun's performance to different materials and screw sizes, enhancing control and efficiency in various applications.

What are the benefits of using a screw gun with a pistol grip?

A screw gun with a pistol grip offers several benefits:

1. **Ergonomic Design**: The pistol grip design provides a natural hand position, reducing strain and fatigue during prolonged use. This ergonomic advantage is particularly beneficial for professionals who use the tool for extended periods.

2. **Improved Control**: The pistol grip allows for better control and precision when driving screws. The grip design facilitates a firm hold, enabling users to apply consistent pressure and maintain stability, which is crucial for accuracy.

3. **Ease of Use**: The intuitive design of a pistol grip makes it easier for users to operate the screw gun, even for those with less experience. The trigger mechanism is conveniently positioned for quick and easy access, enhancing operational efficiency.

4. **Versatility**: Pistol grip screw guns are versatile and can be used in various applications, from construction to DIY projects. Their design allows for easy maneuverability in tight or awkward spaces, making them suitable for a wide range of tasks.

5. **Increased Productivity**: The ergonomic and user-friendly design of a pistol grip screw gun can lead to increased productivity. Users can work faster and more efficiently, reducing the time required to complete tasks.

6. **Reduced Risk of Injury**: By minimizing hand and wrist strain, the pistol grip design helps reduce the risk of repetitive strain injuries, such as carpal tunnel syndrome, which can occur with prolonged use of less ergonomic tools.

7. **Compact and Lightweight**: Many pistol grip screw guns are compact and lightweight, making them easy to carry and handle. This portability is advantageous for professionals who need to transport their tools between job sites.

Overall, a screw gun with a pistol grip combines comfort, control, and efficiency, making it a valuable tool for both professional and amateur users.

How does an auto-feed collation attachment work with a screw gun?

An auto-feed collation attachment works with a screw gun by automating the process of driving screws, thereby increasing efficiency and reducing manual labor. The attachment is designed to hold a strip or coil of collated screws, which are pre-aligned and connected by a plastic or paper strip. This setup allows for rapid and continuous feeding of screws into the screw gun without the need for manual loading.

The attachment is mounted onto the screw gun, typically at the front where the bit is located. It aligns the screws with the bit, ensuring precise placement and driving. As the user activates the screw gun, the attachment automatically advances the next screw into position. This is achieved through a mechanism that synchronizes with the gun's trigger action, often using a feed pawl or similar device to push the screws forward.

The screw gun's motor provides the necessary torque to drive the screws into the material, while the attachment ensures a consistent feed rate and alignment. The depth of drive can usually be adjusted to accommodate different materials and screw lengths, ensuring that screws are driven to the desired depth without over-penetration.

Overall, the auto-feed collation attachment streamlines the screw-driving process, making it faster and more efficient, especially in repetitive tasks like drywall installation, decking, or subflooring. It reduces the need for manual handling of individual screws, minimizes the risk of dropping or losing screws, and helps maintain a steady workflow, ultimately enhancing productivity and reducing fatigue for the user.

What are the advantages of using a corded screw gun over a cordless one?

1. **Consistent Power Supply**: Corded screw guns provide a continuous power supply, ensuring consistent performance without the need for battery recharging or replacement.

2. **Higher Torque and Speed**: Typically, corded models offer higher torque and speed, making them suitable for heavy-duty tasks and prolonged use.

3. **No Downtime**: With no batteries to charge, corded screw guns eliminate downtime, allowing for uninterrupted work sessions.

4. **Lighter Weight**: Without the added weight of a battery, corded screw guns are generally lighter, reducing user fatigue during extended use.

5. **Cost-Effective**: Corded screw guns are often less expensive than their cordless counterparts, both in initial purchase and in the long-term, as there are no battery replacements needed.

6. **Durability and Longevity**: Corded tools tend to have a longer lifespan due to fewer components that can wear out, such as batteries.

7. **Consistent Performance in Cold Weather**: Corded screw guns are not affected by cold temperatures, which can reduce battery efficiency in cordless models.

8. **Ideal for Stationary Work**: For tasks that do not require mobility, such as assembly line work or workshop projects, corded screw guns are ideal.

9. **No Battery Maintenance**: Users do not need to worry about battery maintenance, such as charging cycles or storage conditions.

10. **Environmentally Friendly**: Without batteries, corded screw guns avoid the environmental impact associated with battery disposal and recycling.

What are the benefits of using a cordless screw gun?

The benefits of using a cordless screw gun include:

1. **Portability**: Cordless screw guns are highly portable, allowing users to move freely without being tethered to a power outlet. This is particularly advantageous for tasks in remote locations or large workspaces.

2. **Convenience**: Without the need for cords, setup and storage are simplified. Users can quickly start and finish tasks without dealing with tangled cords or finding extension cables.

3. **Versatility**: Cordless screw guns can be used in various environments, including tight spaces and outdoor settings, where access to power might be limited.

4. **Safety**: The absence of cords reduces the risk of tripping hazards and electrical accidents, making the work environment safer.

5. **Efficiency**: Modern cordless screw guns often come with powerful batteries that provide sufficient torque and speed for most tasks, ensuring efficient performance comparable to corded models.

6. **Advanced Features**: Many cordless models include features like adjustable torque settings, LED lights for better visibility, and ergonomic designs to reduce user fatigue.

7. **Reduced Noise**: Cordless screw guns tend to operate more quietly than their corded counterparts, which can be beneficial in noise-sensitive environments.

8. **Battery Technology**: Advances in battery technology, such as lithium-ion batteries, offer longer run times and faster charging, enhancing productivity.

9. **Environmental Considerations**: Cordless tools eliminate the need for generators or additional power sources, reducing fuel consumption and emissions in off-grid locations.

10. **Flexibility**: Cordless screw guns can be used for a wide range of applications, from light household tasks to professional construction projects, making them a versatile tool in any toolkit.

How do you maintain a screw gun for optimal performance?

1. **Regular Cleaning**: After each use, wipe down the exterior with a clean cloth to remove dust and debris. Use compressed air to blow out any particles from vents and crevices.

2. **Inspect and Tighten**: Regularly check for loose screws or parts. Tighten any that have become loose to prevent damage or malfunction.

3. **Lubrication**: Apply a light machine oil to moving parts, such as the chuck and trigger mechanism, to ensure smooth operation. Avoid over-lubricating, as excess oil can attract dust.

4. **Battery Care**: For cordless models, charge batteries fully before use and avoid letting them completely discharge. Store batteries in a cool, dry place and remove them from the tool when not in use.

5. **Check the Cord**: For corded models, inspect the power cord for any signs of wear or damage. Replace the cord if necessary to prevent electrical hazards.

6. **Bit Maintenance**: Regularly inspect and replace worn or damaged bits. Sharp, undamaged bits ensure efficient operation and reduce strain on the motor.

7. **Motor Maintenance**: Listen for unusual noises that may indicate motor issues. If the motor seems to be struggling, it may need professional servicing.

8. **Storage**: Store the screw gun in a dry, dust-free environment. Use a protective case if available to prevent physical damage.

9. **Follow Manufacturer’s Guidelines**: Adhere to the maintenance schedule and guidelines provided in the user manual for specific care instructions.

10. **Professional Servicing**: Periodically have the tool serviced by a professional to ensure all components are in good working order and to address any potential issues.