Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Tools

- Hand Tools

- Screwdrivers Nut Drivers Keys

- Screwdrivers Sets

.....Read More

Frequently Asked Questions

What are the different types of screwdriver tips and their uses?

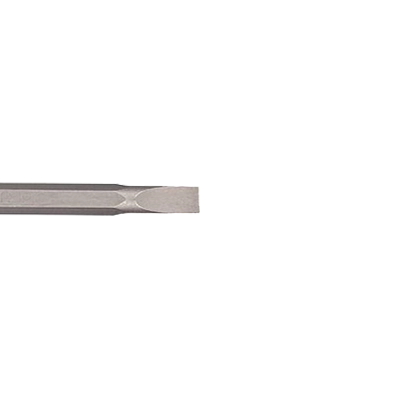

1. **Flathead (Slotted):** A single flat blade fits into a straight, linear slot. Used for simple applications like furniture assembly and electrical work.

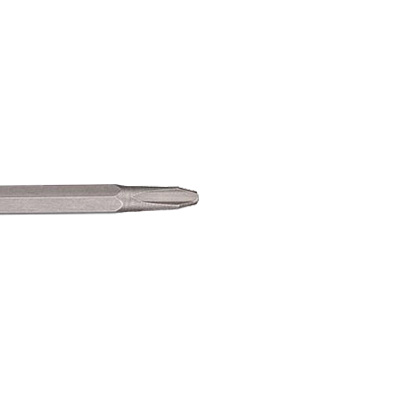

2. **Phillips:** Cross-shaped tip designed to prevent over-tightening. Common in electronics, appliances, and automotive industries.

3. **Pozidriv:** Similar to Phillips but with additional lines for better grip. Used in European applications, especially woodworking.

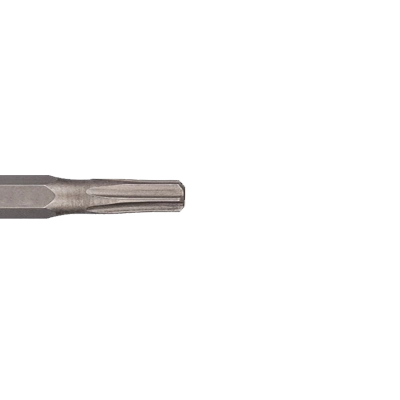

4. **Torx (Star):** Six-pointed star shape provides high torque transfer. Common in automotive, electronics, and computer industries.

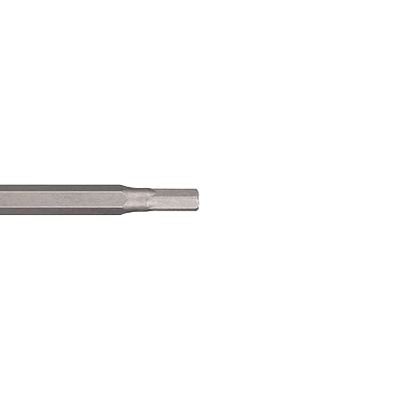

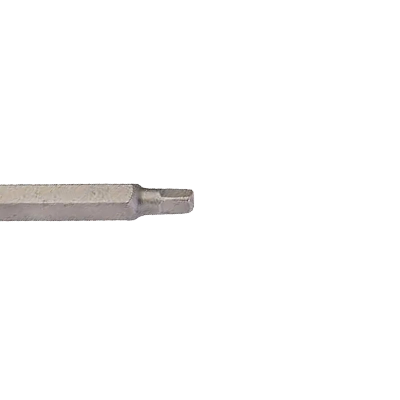

5. **Hex (Allen):** Hexagonal tip used for hexagonal socket screws. Found in furniture assembly and bicycle repairs.

6. **Robertson (Square):** Square-shaped tip offers high torque and reduced cam-out. Popular in woodworking and construction in Canada.

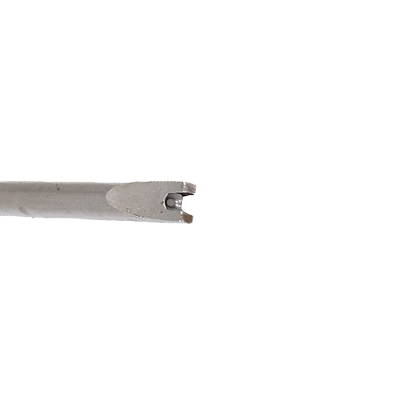

7. **Tri-Wing:** Three-winged tip used in electronics and aerospace for tamper-resistant screws.

8. **Torq-Set:** Offset cruciform design used in aerospace and military applications for tamper resistance.

9. **Spanner (Snake Eyes):** Two-pin tip used for security screws in electronics and public installations.

10. **Clutch Head:** Bow-tie shaped tip used in automotive and vintage applications.

11. **JIS (Japanese Industrial Standard):** Similar to Phillips but designed for Japanese products to prevent cam-out.

12. **Tri-Point:** Three-pointed tip used in electronics, especially in Apple products, for security.

13. **Pentalobe:** Five-pointed star shape used in Apple devices for tamper resistance.

14. **Double Hex:** Twelve-pointed star shape used in high-torque applications like automotive.

15. **Frearson (Reed and Prince):** Cross-shaped like Phillips but with a sharper tip for precision work in marine applications.

How do you choose the right screwdriver size for a screw?

To choose the right screwdriver size for a screw, follow these steps:

1. **Identify the Screw Type**: Determine whether the screw is a flathead, Phillips, Torx, or another type. This will guide you to the correct screwdriver head shape.

2. **Match the Screwdriver Tip to the Screw Head**: Ensure the screwdriver tip fits snugly into the screw head. For flathead screws, the blade should fill the slot without overhanging. For Phillips screws, the tip should fit into the cross without wobbling. For Torx screws, the star-shaped tip should match the screw's pattern.

3. **Check the Screwdriver Size**: Screwdrivers are often numbered or sized. For Phillips, sizes range from 000 (smallest) to 4 (largest). For flathead, measure the blade width and thickness. For Torx, sizes are marked as T followed by a number (e.g., T10, T15).

4. **Test the Fit**: Insert the screwdriver into the screw head. It should fit securely without excessive play. A proper fit minimizes the risk of stripping the screw.

5. **Consider the Screw Size**: Larger screws require larger screwdrivers to provide adequate torque. Match the screwdriver size to the screw's diameter and length.

6. **Use a Screwdriver Set**: If unsure, use a set with multiple sizes and types to find the best fit.

7. **Avoid Over-Tightening**: Use the correct size to prevent damaging the screw or screwdriver.

By following these steps, you ensure efficient and safe screw driving, reducing the risk of damage to both the screw and the tool.

What is the purpose of a torque screwdriver?

A torque screwdriver is a precision tool designed to apply a specific amount of torque to a fastener, such as a screw or bolt. Its primary purpose is to ensure that fasteners are tightened to the correct tension, preventing over-tightening or under-tightening, which can lead to damage or failure of the components being assembled.

In various industries, such as electronics, automotive, aerospace, and manufacturing, maintaining precise torque levels is crucial for the safety, reliability, and performance of the assembled products. Over-tightening can strip threads, damage components, or cause stress fractures, while under-tightening can result in loose connections, leading to malfunctions or safety hazards.

Torque screwdrivers are equipped with a mechanism that allows the user to set a specific torque value. Once the desired torque is reached, the tool typically emits a click or releases a clutch to prevent further tightening. This ensures consistency and accuracy in fastening, which is essential for quality control and compliance with industry standards.

Additionally, torque screwdrivers are used in applications where delicate materials or components are involved, requiring careful handling to avoid damage. They are also valuable in assembly lines, where speed and precision are necessary to maintain productivity and quality.

Overall, the purpose of a torque screwdriver is to provide controlled and repeatable torque application, enhancing the integrity and longevity of assembled products while minimizing the risk of damage or failure.

How do you use a multi-bit screwdriver?

To use a multi-bit screwdriver, follow these steps:

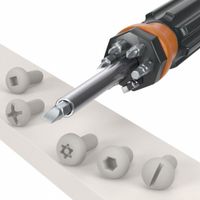

1. **Select the Bit**: Identify the type of screw you need to work with (e.g., Phillips, flathead, Torx). Choose the corresponding bit from the set included with the screwdriver.

2. **Insert the Bit**: Most multi-bit screwdrivers have a magnetic or locking mechanism in the shaft. Insert the chosen bit into the tip of the screwdriver until it is securely held in place.

3. **Adjust the Handle**: Some multi-bit screwdrivers have adjustable handles for better grip or torque. Adjust the handle if necessary to fit your hand comfortably.

4. **Engage the Screw**: Place the tip of the bit into the screw head. Ensure it fits snugly to avoid stripping the screw.

5. **Apply Pressure**: Apply downward pressure on the screwdriver to keep the bit engaged with the screw head.

6. **Turn the Screwdriver**: Rotate the handle clockwise to tighten the screw or counterclockwise to loosen it. Use steady, even pressure to avoid slipping.

7. **Change Bits**: If you need to switch to a different screw type, pull the current bit out and replace it with the new one, following the same insertion process.

8. **Storage**: After use, store the bits in their designated slots in the handle or case to prevent loss.

9. **Maintenance**: Keep the bits clean and free from rust. Occasionally check the mechanism for wear and tear to ensure it functions smoothly.

By following these steps, you can efficiently use a multi-bit screwdriver for various tasks, ensuring versatility and convenience in your projects.

How do you magnetize or demagnetize a screwdriver?

To magnetize a screwdriver, you can use a strong magnet. Hold the screwdriver by the handle and stroke the metal shaft with the magnet, moving in one direction only, from the handle to the tip. Repeat this process several times, ensuring consistent contact and direction. This aligns the domains within the metal, magnetizing the screwdriver.

To demagnetize a screwdriver, you can use a demagnetizer tool or an alternating current (AC) source. For a demagnetizer tool, simply pass the screwdriver through the tool's magnetic field as per the manufacturer's instructions. If using an AC source, carefully move the screwdriver in and out of the field, gradually increasing the distance to randomize the domains and remove magnetism. Alternatively, heating the screwdriver to a high temperature (above its Curie point) and allowing it to cool can also demagnetize it, but this may affect the tool's temper and should be done with caution.

What are the benefits of using a screwdriver set?

A screwdriver set offers several benefits, enhancing both convenience and efficiency in various tasks:

1. **Versatility**: A screwdriver set typically includes multiple types and sizes of screwdrivers, such as flathead, Phillips, Torx, and more. This variety allows users to tackle a wide range of tasks, from assembling furniture to repairing electronics.

2. **Cost-Effective**: Purchasing a set is often more economical than buying individual screwdrivers. It provides all necessary tools in one package, reducing the need for multiple purchases.

3. **Space-Saving**: A compact set takes up less space than storing individual tools. Many sets come in organized cases, making storage and transport easier and more efficient.

4. **Convenience**: Having a complete set on hand means you’re always prepared for any task that requires a screwdriver. This eliminates the need to search for the right tool, saving time and effort.

5. **Improved Efficiency**: With the right tool readily available, tasks can be completed more quickly and accurately. This is particularly beneficial for professionals who need to maintain productivity.

6. **Durability**: Quality screwdriver sets are made from robust materials, ensuring longevity and reliability. This durability means they can withstand frequent use without wearing out quickly.

7. **Ergonomic Design**: Many sets feature screwdrivers with ergonomic handles, providing a comfortable grip and reducing hand fatigue during extended use.

8. **Precision**: Sets often include precision screwdrivers for delicate tasks, such as working on small electronics or intricate mechanical components, ensuring accuracy and care.

9. **Safety**: Using the correct screwdriver reduces the risk of damaging screws or the work surface, preventing accidents and ensuring a secure fit.

10. **Professional Appearance**: For tradespeople, having a complete set presents a professional image, demonstrating preparedness and attention to detail.

How do you maintain and care for screwdrivers to ensure longevity?

To maintain and care for screwdrivers, follow these steps:

1. **Cleaning**: After each use, wipe the screwdriver with a clean, dry cloth to remove dirt, grease, and debris. For stubborn grime, use a mild detergent and water, then dry thoroughly to prevent rust.

2. **Rust Prevention**: Apply a light coat of machine oil or a rust inhibitor to the metal parts to protect against corrosion. Store screwdrivers in a dry place to minimize exposure to moisture.

3. **Storage**: Store screwdrivers in a toolbox or on a rack to prevent damage. Ensure they are organized by size and type to avoid unnecessary wear and tear.

4. **Inspection**: Regularly inspect screwdrivers for signs of wear, such as bent shafts or chipped tips. Replace any damaged tools to prevent injury and ensure effective use.

5. **Sharpening**: For flathead screwdrivers, occasionally sharpen the tip using a file to maintain a precise edge. Be cautious not to alter the original shape.

6. **Handle Care**: Keep handles clean and free from oil or grease to ensure a firm grip. If the handle is wooden, occasionally apply a wood conditioner to prevent drying and cracking.

7. **Avoid Misuse**: Use screwdrivers only for their intended purpose. Avoid using them as pry bars, chisels, or for any task that could damage the tool.

8. **Proper Use**: Apply the correct amount of force and use the right size and type of screwdriver for the screw to prevent stripping and damage.

By following these maintenance and care tips, you can extend the life of your screwdrivers and ensure they remain effective tools in your toolkit.