Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Test Instruments

- Electrical Power Testing

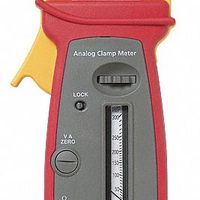

- Clamp Meters

.....Read More

Frequently Asked Questions

What is a clamp meter used for?

A clamp meter is an electrical testing tool used primarily to measure the current flowing through a conductor without the need to make physical contact or disconnect the circuit. It combines a basic digital multimeter with a current sensor. The primary function of a clamp meter is to measure alternating current (AC) and, in some models, direct current (DC) as well.

The device features jaws that open and close around a conductor, allowing it to measure the magnetic field produced by the current flowing through the wire. This non-intrusive method of measurement is particularly useful for high-current applications where breaking the circuit to insert a traditional ammeter would be impractical or unsafe.

Clamp meters are widely used by electricians, technicians, and engineers for various applications, including troubleshooting electrical problems, verifying system performance, and ensuring equipment is operating within specified parameters. They are essential in industrial, commercial, and residential settings for tasks such as checking the load on circuits, diagnosing electrical faults, and performing maintenance on electrical systems.

In addition to current measurement, many clamp meters offer additional functionalities, such as measuring voltage, resistance, continuity, frequency, and sometimes even temperature. Advanced models may include features like inrush current measurement, data logging, and wireless connectivity for remote monitoring.

Overall, clamp meters are valued for their safety, convenience, and versatility, making them indispensable tools for professionals working with electrical systems.

How do you use a digital clamp meter?

To use a digital clamp meter, follow these steps:

1. **Safety First**: Ensure you are wearing appropriate personal protective equipment. Verify that the meter is rated for the voltage and current levels you will be measuring.

2. **Inspect the Meter**: Check the meter for any physical damage. Ensure the batteries are charged and the display is functioning properly.

3. **Select the Correct Mode**: Turn the rotary switch to the desired measurement type (AC current, DC current, voltage, resistance, etc.). For current measurements, use the clamp; for voltage or resistance, use the test leads.

4. **Zero the Meter**: If your meter has a zero function, use it to eliminate any residual readings before taking measurements.

5. **Open the Clamp**: Press the lever to open the jaws of the clamp.

6. **Position the Clamp**: Place the conductor (wire) you wish to measure within the jaws. Ensure the clamp is fully closed around the conductor for accurate readings. Only one conductor should be inside the clamp at a time for current measurements.

7. **Read the Measurement**: Observe the reading on the digital display. For current, the reading will be in amperes. For voltage or resistance, connect the test leads to the circuit and read the display.

8. **Record the Data**: Note the measurement for your records. If the meter has data hold or memory functions, use them to store readings.

9. **Turn Off the Meter**: After use, turn off the meter to conserve battery life.

10. **Store Properly**: Store the meter in a safe, dry place to prevent damage.

Always refer to the user manual specific to your digital clamp meter model for detailed instructions and safety guidelines.

What is the difference between a clamp meter and a multimeter?

A clamp meter and a multimeter are both essential tools for electrical measurements, but they serve different purposes and have distinct features.

A clamp meter is primarily used for measuring current without the need to make direct contact with the conductor. It features jaws that open and close around a conductor, allowing for non-intrusive current measurement. This makes it particularly useful for measuring high currents in industrial settings or when it's impractical to disconnect a circuit. Modern clamp meters often include additional functions such as measuring voltage, resistance, and continuity, but their primary advantage is the ability to measure current safely and efficiently.

On the other hand, a multimeter is a versatile tool designed to measure various electrical parameters, including voltage, current, resistance, capacitance, and sometimes frequency and temperature. It requires direct contact with the circuit through test leads. Multimeters are available in analog and digital forms, with digital multimeters (DMMs) being more common due to their precision and ease of use. They are ideal for troubleshooting and diagnosing electrical problems in a wide range of applications, from household electronics to automotive systems.

The key difference lies in their primary function: clamp meters excel in measuring current without circuit interruption, while multimeters offer a broader range of measurements but typically require circuit contact. For professionals and hobbyists, the choice between the two depends on the specific requirements of the task at hand. In many cases, having both tools available provides the most comprehensive capability for electrical testing and diagnostics.

Can a clamp meter measure voltage?

Yes, a clamp meter can measure voltage, but it depends on the specific model and its features. Traditionally, clamp meters are designed primarily for measuring current without the need to make direct contact with a conductor. They achieve this by clamping around a wire to detect the magnetic field generated by the current flow.

However, many modern clamp meters are equipped with additional functionalities, including the ability to measure voltage. These models typically have test leads that can be connected to the circuit to measure voltage, similar to a standard multimeter. The voltage measurement feature allows users to measure both AC and DC voltages, depending on the meter's specifications.

When using a clamp meter to measure voltage, it is important to ensure that the meter is set to the correct mode and range to avoid damage to the device or inaccurate readings. Users should also be aware of the maximum voltage rating of the clamp meter to ensure safe operation.

In summary, while the primary function of a clamp meter is to measure current, many modern models are versatile tools that can also measure voltage, resistance, and other electrical parameters. Always refer to the user manual of the specific clamp meter model to understand its capabilities and limitations.

How accurate are clamp meters?

Clamp meters are generally accurate for their intended purpose, which is measuring AC current without direct contact with the conductor. The accuracy of a clamp meter can vary based on several factors, including the quality of the device, the range of current being measured, and the specific model. Typically, high-quality clamp meters from reputable manufacturers offer accuracy within 1% to 3% for AC current measurements.

For DC current measurements, which are available in more advanced models, the accuracy might be slightly lower due to the complexity of measuring DC currents with a clamp meter. The accuracy for voltage measurements, which many clamp meters also provide, is usually comparable to that of standard multimeters, often within 0.5% to 1%.

The accuracy can also be affected by external factors such as the presence of nearby magnetic fields, the positioning of the conductor within the clamp, and the resolution of the meter. To ensure optimal accuracy, it is important to follow the manufacturer's guidelines, such as zeroing the meter before use and ensuring the conductor is centered within the clamp.

Calibration is another critical factor in maintaining accuracy. Regular calibration, as recommended by the manufacturer, helps ensure that the clamp meter provides precise readings over time.

In summary, while clamp meters are generally accurate for their intended applications, the specific accuracy can vary based on the model, measurement type, and external conditions. For critical applications, it is advisable to use a high-quality, well-calibrated clamp meter and to be aware of its limitations.

What are the advantages of using a digital clamp meter over an analog one?

1. **Accuracy and Precision**: Digital clamp meters generally offer higher accuracy and precision compared to analog meters. They provide exact numerical readings, reducing the chance of human error in interpreting needle positions.

2. **Ease of Use**: Digital displays are easier to read, especially in low-light conditions, as they often come with backlit screens. This makes them more user-friendly compared to analog meters, which require reading a scale.

3. **Additional Features**: Digital clamp meters often come with advanced features such as auto-ranging, data hold, and the ability to measure additional parameters like frequency, capacitance, and temperature, which are not typically available in analog models.

4. **Data Logging and Connectivity**: Many digital clamp meters have data logging capabilities and can connect to computers or smartphones via Bluetooth or USB for data analysis and storage, which is not possible with analog meters.

5. **Durability and Maintenance**: Digital meters are generally more robust and require less maintenance. They are less susceptible to mechanical wear and tear compared to analog meters, which have moving parts.

6. **Safety**: Digital clamp meters often include safety features such as overload protection and non-contact voltage detection, enhancing user safety during electrical measurements.

7. **Resolution**: Digital meters provide higher resolution, allowing for more detailed readings, which is particularly useful in applications requiring precise measurements.

8. **Auto Calibration**: Many digital clamp meters come with auto-calibration features, ensuring consistent accuracy without the need for manual adjustments.

9. **Versatility**: Digital clamp meters can measure both AC and DC currents, while many analog meters are limited to AC measurements.

10. **Portability**: Digital clamp meters are often more compact and lightweight, making them easier to carry and use in various environments.

How do you maintain and calibrate a clamp meter?

To maintain and calibrate a clamp meter, follow these steps:

1. **Regular Inspection**: Frequently inspect the clamp meter for physical damage, wear, or corrosion. Check the jaws for alignment and cleanliness to ensure accurate readings.

2. **Cleaning**: Use a soft, dry cloth to clean the exterior. For stubborn dirt, slightly dampen the cloth with water. Avoid using solvents or abrasives. Clean the jaws with a non-abrasive cleaner to remove any residue that might affect conductivity.

3. **Battery Check**: Regularly check and replace the batteries as needed. Low battery power can lead to inaccurate readings. Always use the recommended battery type.

4. **Storage**: Store the clamp meter in a protective case when not in use. Keep it in a dry, dust-free environment to prevent damage.

5. **Calibration**: Calibration should be performed annually or as specified by the manufacturer. Use a calibration source or standard that is traceable to national standards. Follow these steps:

- **Zero Adjustment**: Before calibration, ensure the meter reads zero when the jaws are closed and no current is present.

- **Current Calibration**: Use a known current source. Clamp the meter around the conductor and compare the reading with the known value. Adjust the meter as necessary.

- **Voltage Calibration**: Connect the meter to a known voltage source. Compare the reading with the known value and adjust if needed.

- **Resistance Calibration**: Use a known resistor. Measure the resistance and adjust the meter to match the known value.

6. **Professional Calibration**: If the meter is out of specification or if you lack the equipment for calibration, send it to a professional calibration service.

7. **Documentation**: Keep records of all maintenance and calibration activities, including dates and results, to ensure compliance and traceability.