Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Steel

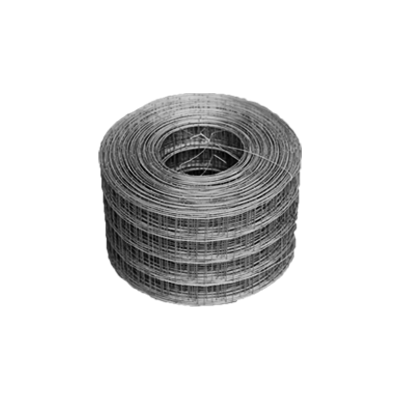

- Wire And Fence Products Fence Products

- Welded Rolls

.....Read More

Frequently Asked Questions

What are welded rolls used for?

Welded rolls are primarily used in the manufacturing and processing industries for shaping, forming, and finishing metal sheets and other materials. They are integral components in rolling mills, where they help in the production of metal products by applying pressure to the material, thereby reducing its thickness and altering its shape. These rolls are crucial in the production of steel, aluminum, and other metal products, including pipes, tubes, and structural components.

In the steel industry, welded rolls are used in hot and cold rolling processes. In hot rolling, they help in reducing the thickness of steel slabs at high temperatures, making the material more malleable and easier to shape. In cold rolling, welded rolls are used to further refine the surface finish and mechanical properties of the metal, enhancing its strength and surface quality.

Welded rolls are also employed in the production of welded tubes and pipes. In this process, flat metal sheets are passed through a series of rolls that gradually bend the material into a cylindrical shape. The edges of the sheet are then welded together to form a continuous tube or pipe. This method is widely used in the production of pipes for plumbing, construction, and industrial applications.

Additionally, welded rolls are used in the production of various metal components and products, such as automotive parts, appliances, and machinery. They are essential in ensuring the precision and quality of the final products, as they provide consistent pressure and shaping capabilities.

Overall, welded rolls are vital tools in the metalworking industry, enabling the efficient and precise production of a wide range of metal products.

How are welded rolls manufactured?

Welded rolls are manufactured through a series of precise and controlled processes to ensure durability and performance. The process begins with the selection of high-quality steel or alloy materials, which are then cut into the required dimensions. These materials are typically in the form of plates or sheets.

The next step involves forming the material into a cylindrical shape. This is achieved using a rolling machine that bends the flat material into a round form. Once the desired shape is achieved, the edges of the material are prepared for welding. This preparation may include cleaning, beveling, or grinding to ensure a clean and strong weld.

Welding is then performed, often using techniques such as submerged arc welding (SAW) or gas metal arc welding (GMAW), depending on the material and application requirements. These methods provide deep penetration and strong welds, essential for the structural integrity of the rolls. The welding process is carefully monitored to prevent defects and ensure uniformity.

After welding, the rolls undergo a series of finishing processes. These may include heat treatment to relieve stresses and enhance mechanical properties, as well as machining to achieve precise dimensions and surface finish. Non-destructive testing methods, such as ultrasonic testing or radiography, are employed to inspect the welds for any internal defects.

Finally, the rolls are subjected to quality control checks to ensure they meet the required specifications and standards. This comprehensive manufacturing process results in welded rolls that are robust, reliable, and suitable for various industrial applications.

What materials are used in welded rolls?

Welded rolls are typically constructed using a variety of materials, each chosen for its specific properties that contribute to the roll's performance in industrial applications. Common materials include:

1. **Carbon Steel**: Widely used due to its strength, durability, and cost-effectiveness. It is suitable for general-purpose applications where high strength is required.

2. **Alloy Steel**: Contains additional alloying elements like chromium, nickel, and molybdenum, which enhance properties such as toughness, wear resistance, and corrosion resistance. This makes it ideal for more demanding applications.

3. **Stainless Steel**: Known for its excellent corrosion resistance and strength, stainless steel is used in environments where exposure to moisture or chemicals is a concern. It is often used in the food processing and pharmaceutical industries.

4. **Tool Steel**: Offers high hardness and resistance to abrasion, making it suitable for rolls that will be subjected to high wear conditions. It is often used in metal forming and cutting applications.

5. **Cast Iron**: Provides good wear resistance and damping properties, making it suitable for applications where vibration reduction is important. However, it is more brittle compared to steel.

6. **Composite Materials**: These may include a combination of metals and non-metals, such as ceramics, to provide a balance of strength, wear resistance, and thermal stability.

7. **Clad Materials**: Involves bonding a layer of corrosion-resistant material, like stainless steel, onto a base material, such as carbon steel, to combine the benefits of both materials.

The choice of material depends on factors such as the intended application, operating environment, required mechanical properties, and cost considerations. Each material offers a unique set of advantages that can be leveraged to optimize the performance and longevity of welded rolls in specific industrial settings.

What are the benefits of using welded rolls?

Welded rolls offer several benefits in industrial applications, particularly in the manufacturing and processing sectors.

1. **Strength and Durability**: Welded rolls are known for their enhanced structural integrity. The welding process fuses the materials together, creating a strong bond that can withstand high stress and pressure, making them ideal for heavy-duty applications.

2. **Cost-Effectiveness**: The production of welded rolls can be more economical compared to other methods. Welding allows for the use of less expensive materials without compromising on strength, reducing overall production costs.

3. **Customization**: Welded rolls can be easily customized to meet specific requirements. The welding process allows for the creation of complex shapes and sizes, catering to unique industrial needs.

4. **Improved Performance**: The seamless nature of welded rolls reduces the risk of material failure and enhances performance. This is particularly beneficial in applications involving high-speed operations or where precision is critical.

5. **Corrosion Resistance**: By selecting appropriate materials and welding techniques, welded rolls can be made resistant to corrosion, extending their lifespan in harsh environments.

6. **Reduced Maintenance**: The durability and strength of welded rolls mean they require less frequent maintenance and replacement, leading to reduced downtime and operational costs.

7. **Versatility**: Welded rolls can be used in a wide range of applications, from paper and textile manufacturing to metal processing and food production, due to their adaptability and robust nature.

8. **Energy Efficiency**: The efficient transfer of energy through welded rolls can lead to energy savings in processes that involve rolling or conveying materials.

Overall, welded rolls provide a reliable, cost-effective, and versatile solution for various industrial applications, enhancing productivity and efficiency.

How do you maintain welded rolls?

To maintain welded rolls effectively, follow these steps:

1. **Regular Inspection**: Conduct routine visual inspections to identify any signs of wear, cracks, or deformation. Use non-destructive testing methods like ultrasonic or magnetic particle testing for deeper analysis.

2. **Cleaning**: Keep the rolls clean from debris, dust, and any material build-up. Use appropriate cleaning agents that do not corrode the metal surface.

3. **Lubrication**: Apply suitable lubricants to reduce friction and wear. Ensure the lubricant is compatible with the roll material and operating conditions.

4. **Alignment**: Regularly check and adjust the alignment of the rolls to prevent uneven wear and ensure optimal performance.

5. **Surface Treatment**: Apply surface treatments like hardening or coating to enhance wear resistance and extend the roll's lifespan.

6. **Temperature Control**: Monitor and control the operating temperature to prevent overheating, which can lead to thermal fatigue and cracking.

7. **Balancing**: Ensure the rolls are properly balanced to avoid vibrations that can cause premature wear or damage.

8. **Repair and Reconditioning**: Address minor damages promptly through welding or grinding. For significant wear, consider reconditioning the rolls by resurfacing or replacing worn sections.

9. **Documentation**: Maintain detailed records of maintenance activities, inspections, and any repairs performed to track the roll's condition over time.

10. **Training**: Ensure that personnel involved in maintenance are adequately trained and aware of the best practices and safety protocols.

By adhering to these maintenance practices, the longevity and performance of welded rolls can be significantly enhanced, reducing downtime and operational costs.

What are common defects in welded rolls?

Common defects in welded rolls include:

1. **Porosity**: Gas pockets or voids trapped in the weld metal, often caused by contamination or improper shielding gas.

2. **Cracks**: These can occur in various forms such as hot cracks, cold cracks, or stress cracks, often due to rapid cooling, high residual stress, or improper welding techniques.

3. **Incomplete Fusion**: Occurs when the weld metal fails to properly fuse with the base metal or preceding weld bead, often due to insufficient heat or improper technique.

4. **Incomplete Penetration**: The weld metal does not extend through the joint thickness, often due to inadequate heat input or incorrect joint preparation.

5. **Undercut**: A groove melted into the base metal adjacent to the weld toe or root, often caused by excessive welding speed or current.

6. **Overlap**: Occurs when the weld metal flows over the base metal surface without fusing, often due to excessive weld metal deposition or incorrect angle.

7. **Slag Inclusions**: Non-metallic solid material trapped in the weld, often due to improper cleaning between passes or incorrect welding parameters.

8. **Distortion**: Warping of the welded component due to uneven heating and cooling, often managed by proper fixturing and welding sequence.

9. **Spatter**: Small metal droplets expelled during welding, often due to excessive current or incorrect arc length.

10. **Burn-through**: Excessive penetration causing holes in the base metal, often due to excessive heat input or thin base material.

11. **Lamellar Tearing**: Occurs in rolled steel when welds are made perpendicular to the rolling direction, often due to high through-thickness stress.

12. **Residual Stresses**: Stresses remaining in the material post-welding, often leading to distortion or cracking.

13. **Weld Bead Irregularities**: Inconsistent bead shape or size, often due to improper technique or parameter settings.

How do you select the right welded roll for an application?

Selecting the right welded roll for an application involves several key considerations:

1. **Material Compatibility**: Choose a roll material that is compatible with the material being processed. Consider factors like corrosion resistance, thermal conductivity, and wear resistance.

2. **Load Capacity**: Determine the load the roll will bear. This includes static and dynamic loads. Ensure the roll can handle the maximum expected load without deformation or failure.

3. **Surface Finish**: The surface finish of the roll should match the requirements of the application. A smoother finish may be necessary for applications requiring minimal friction or specific surface interactions.

4. **Roll Diameter and Length**: Select the appropriate diameter and length based on the machine design and the material being processed. Ensure the roll fits within the machine's specifications and can handle the material width.

5. **Operating Environment**: Consider the operating environment, including temperature, humidity, and exposure to chemicals. The roll material and design should withstand these conditions without degradation.

6. **Speed and Rotation**: Evaluate the speed at which the roll will operate. High-speed applications may require rolls with specific balance and alignment to prevent vibration and ensure smooth operation.

7. **Maintenance and Durability**: Consider the ease of maintenance and the expected lifespan of the roll. Opt for designs that facilitate easy inspection, cleaning, and replacement.

8. **Cost**: Balance the cost of the roll with its performance and lifespan. While initial costs are important, consider the total cost of ownership, including maintenance and replacement costs.

9. **Supplier Reputation**: Choose a reputable supplier with a track record of providing high-quality welded rolls. Check for certifications and customer reviews.

10. **Customization Needs**: Determine if the application requires custom features, such as specific grooves or coatings, and ensure the supplier can accommodate these needs.