Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Raw Materials

- Metals

- Carbon Steel

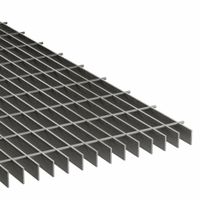

- Carbon Steel Grating Stair Treads

.....Read More

Frequently Asked Questions

What are the benefits of using carbon steel grating in industrial settings?

Carbon steel grating offers several benefits in industrial settings:

1. **Durability**: Carbon steel is known for its strength and ability to withstand heavy loads, making it ideal for high-traffic areas and heavy-duty applications.

2. **Cost-Effectiveness**: Compared to other materials like stainless steel or aluminum, carbon steel is more affordable, providing a cost-effective solution without compromising on performance.

3. **Versatility**: It can be used in various applications, including walkways, platforms, stair treads, and drainage covers, due to its adaptability to different designs and specifications.

4. **High Load-Bearing Capacity**: Carbon steel grating can support substantial weight, making it suitable for environments where heavy machinery or equipment is used.

5. **Slip Resistance**: The grating design provides excellent traction, reducing the risk of slips and falls, which is crucial for maintaining safety in industrial environments.

6. **Corrosion Resistance**: When treated with coatings like galvanization, carbon steel grating offers enhanced resistance to corrosion, extending its lifespan even in harsh conditions.

7. **Ease of Installation and Maintenance**: Its lightweight nature allows for easy handling and installation, while its durability minimizes maintenance requirements.

8. **Thermal Conductivity**: Carbon steel can withstand high temperatures, making it suitable for industries involving heat-intensive processes.

9. **Customizability**: It can be fabricated to meet specific size, shape, and load requirements, ensuring it fits perfectly within the intended application.

10. **Environmental Impact**: Carbon steel is recyclable, contributing to sustainability efforts by reducing waste and conserving resources.

These benefits make carbon steel grating a preferred choice in various industrial applications, balancing performance, safety, and cost.

How do you choose between serrated and smooth surface grating?

Choosing between serrated and smooth surface grating depends on several factors, including safety, application, and environmental conditions.

1. **Safety and Slip Resistance**: Serrated grating is preferred in environments where slip resistance is crucial. The serrated edges provide better traction, making it ideal for areas prone to wet, oily, or icy conditions. This makes it suitable for outdoor walkways, industrial platforms, and areas with heavy foot traffic.

2. **Application and Load Requirements**: Smooth surface grating is often used in applications where aesthetics are important or where the risk of slipping is minimal. It is suitable for indoor use, such as in commercial buildings or areas where wheeled equipment is used, as it allows for easier movement over the surface.

3. **Maintenance and Cleaning**: Smooth grating is easier to clean and maintain, as there are no serrations to trap dirt and debris. This makes it a better choice for environments where hygiene is a priority, such as food processing facilities.

4. **Environmental Conditions**: In corrosive environments, such as chemical plants or coastal areas, the choice of material (e.g., stainless steel, aluminum) may be more critical than the surface type. However, serrated grating can provide additional safety in these challenging conditions.

5. **Cost Considerations**: Serrated grating may be slightly more expensive due to the additional processing required to create the serrations. Budget constraints might influence the decision, especially if the application does not demand high slip resistance.

Ultimately, the choice between serrated and smooth surface grating should be based on a careful assessment of the specific requirements of the application, prioritizing safety, functionality, and cost-effectiveness.

What are the standard sizes and dimensions for carbon steel grating?

Carbon steel grating is commonly used in industrial and commercial applications for flooring, walkways, and platforms. The standard sizes and dimensions for carbon steel grating typically include:

1. **Bearing Bar Size**: The bearing bars are the main load-carrying components. Standard sizes range from 3/4 inch to 2 1/2 inches in height, with thicknesses from 1/8 inch to 1/4 inch.

2. **Spacing**: The spacing between bearing bars is usually 1 inch, 1 3/16 inches, or 1 1/4 inches center-to-center. Cross bars are typically spaced at 4 inches or 2 inches center-to-center.

3. **Panel Size**: Standard panel sizes are typically 3 feet by 24 feet or 4 feet by 24 feet, but custom sizes can be manufactured to fit specific applications.

4. **Load Bar Orientation**: Load bars can be oriented either parallel or perpendicular to the span direction, depending on the load requirements and installation design.

5. **Surface Type**: Gratings can have a plain or serrated surface. Serrated surfaces provide additional slip resistance.

6. **Finish**: Carbon steel grating is often available in a mill finish, but it can also be galvanized for enhanced corrosion resistance.

7. **Type**: Common types include welded, press-locked, and swage-locked grating, each with specific manufacturing processes and applications.

These dimensions and specifications can vary based on manufacturer standards and specific project requirements. Always consult with a manufacturer or supplier for precise specifications tailored to your needs.

How do you install carbon steel stair treads and grating?

1. **Preparation**:

- Measure the area where the stair treads and grating will be installed.

- Ensure the supporting structure is clean, level, and capable of bearing the load.

2. **Material Check**:

- Verify the dimensions and specifications of the carbon steel treads and grating.

- Check for any damage or defects.

3. **Cutting**:

- If necessary, cut the grating to fit the specific dimensions using a saw with a metal-cutting blade.

- Ensure cuts are clean and edges are smooth to prevent injury.

4. **Positioning**:

- Place the stair treads and grating in their designated positions.

- Ensure they are aligned properly with the supporting structure.

5. **Fastening**:

- Use appropriate fasteners such as bolts, clips, or welds to secure the treads and grating.

- For bolting, drill holes in the supporting structure and use nuts and bolts to secure.

- For welding, ensure proper welding techniques to avoid weakening the structure.

6. **Spacing**:

- Maintain consistent spacing between treads and grating to ensure safety and compliance with building codes.

7. **Safety Checks**:

- Ensure all fasteners are tight and secure.

- Check for any sharp edges or protrusions and smooth them out.

8. **Finishing**:

- Apply a protective coating or paint to prevent rust and corrosion.

- Ensure the surface is non-slip, especially in wet conditions.

9. **Inspection**:

- Conduct a final inspection to ensure all components are securely installed and meet safety standards.

10. **Maintenance**:

- Regularly inspect and maintain the treads and grating to ensure longevity and safety.

What maintenance is required for carbon steel grating and stair treads?

Carbon steel grating and stair treads require regular maintenance to ensure safety, longevity, and optimal performance. Here are the key maintenance tasks:

1. **Inspection**: Conduct regular inspections to identify any signs of wear, corrosion, or damage. Look for loose welds, bent bars, or any structural deformities.

2. **Cleaning**: Remove debris, dirt, and any corrosive substances. Use a wire brush or pressure washer for thorough cleaning. Ensure that the grating is free from oil, grease, and other contaminants that can accelerate corrosion.

3. **Corrosion Protection**: Apply a protective coating or paint to prevent rust. Galvanizing or using a rust-inhibitive primer can provide additional protection. Reapply coatings as needed, especially in high-traffic or corrosive environments.

4. **Repair**: Address any damage immediately. Replace or repair bent or broken bars and ensure all welds are secure. For minor rust, use a rust converter or sand the area before applying a protective coating.

5. **Fastener Check**: Ensure all bolts, nuts, and fasteners are tight and in good condition. Replace any that are corroded or damaged to maintain structural integrity.

6. **Load Testing**: Periodically test the grating and treads to ensure they can support the intended load. This is crucial in industrial settings where heavy loads are common.

7. **Environmental Considerations**: In environments with high humidity or exposure to chemicals, increase the frequency of inspections and maintenance to prevent accelerated deterioration.

8. **Documentation**: Keep detailed records of all inspections, maintenance activities, and repairs. This helps in tracking the condition over time and planning future maintenance.

By adhering to these maintenance practices, the lifespan and safety of carbon steel grating and stair treads can be significantly extended.

How do clips for steel grating work and how are they installed?

Clips for steel grating are used to secure grating panels to their supporting structures, ensuring stability and safety. They prevent movement and displacement due to dynamic loads or environmental factors.

There are several types of clips, including saddle clips, G clips, and C clips, each designed for specific applications and grating types.

1. **Saddle Clips**: These are the most common and consist of a top saddle, a bolt, and a nut. The saddle fits over the grating bar, and the bolt passes through the saddle and the grating, securing it to the support structure.

2. **G Clips**: These are used for quick installation without drilling. They have a top piece that grips the grating and a bottom piece that hooks under the support structure. A bolt tightens the assembly.

3. **C Clips**: These are used to connect adjacent grating panels. They have a C-shaped design that fits over the edges of two panels, holding them together.

**Installation Process**:

1. **Positioning**: Place the grating panel on the support structure, ensuring it is properly aligned.

2. **Placing Clips**: Position the clips at the recommended intervals, usually at least one clip per corner and additional clips for larger panels.

3. **Securing**: For saddle clips, insert the bolt through the saddle and grating, then tighten the nut underneath. For G clips, place the top piece over the grating and hook the bottom piece under the support, then tighten the bolt. For C clips, fit them over the edges of adjacent panels and tighten.

4. **Inspection**: Ensure all clips are securely fastened and the grating is stable.

Proper installation of clips is crucial for the safety and longevity of steel grating systems.

What are the safety features of carbon steel stair treads?

Carbon steel stair treads are designed with several safety features to ensure durability and prevent accidents:

1. **Slip Resistance**: Carbon steel stair treads often have a serrated or diamond plate surface to provide traction and reduce the risk of slipping, especially in wet or oily conditions.

2. **Load Bearing Capacity**: These treads are engineered to support heavy loads, making them suitable for industrial and commercial environments where safety is paramount.

3. **Durability**: Carbon steel is known for its strength and resistance to wear and tear, ensuring that the treads maintain their structural integrity over time, even under heavy use.

4. **Corrosion Resistance**: While carbon steel can be prone to rust, many stair treads are treated with coatings or galvanization to enhance their resistance to corrosion, extending their lifespan and maintaining safety.

5. **Open Design**: Some carbon steel stair treads feature an open grid design, which allows debris, water, and other materials to pass through, preventing accumulation that could lead to slipping hazards.

6. **Edge Visibility**: Many treads have contrasting nosing or edge markings to enhance visibility, helping users to see the edge of each step clearly and reducing the risk of missteps.

7. **Customizable Sizes and Shapes**: Carbon steel stair treads can be customized to fit specific dimensions and shapes, ensuring a proper fit and secure installation, which is crucial for safety.

8. **Compliance with Standards**: These treads are often manufactured to meet safety standards and regulations, ensuring they provide adequate protection and performance in various settings.

9. **Ease of Maintenance**: The design and material allow for easy cleaning and maintenance, ensuring that the treads remain safe and functional over time.