Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Raw Materials

- Metals

- Carbon Steel

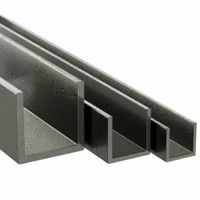

- Carbon Steel Angles Channels

.....Read More

Frequently Asked Questions

What are the differences between carbon steel angle stock and U-channel?

Carbon steel angle stock and U-channel are both structural steel shapes, but they differ in form and application:

1. **Shape**:

- **Angle Stock**: Typically an "L" shape with two legs that meet at a 90-degree angle. The legs can be equal or unequal in length.

- **U-Channel**: Resembles a "U" with two parallel flanges connected by a web. The flanges can be of equal or varying lengths.

2. **Structural Support**:

- **Angle Stock**: Provides support in two directions, making it ideal for corner reinforcement and bracing.

- **U-Channel**: Offers support in one direction, often used for framing, edging, and as a base for other structures.

3. **Applications**:

- **Angle Stock**: Commonly used in construction for frameworks, supports, and brackets. It's also used in manufacturing and repair work.

- **U-Channel**: Used in construction for tracks, posts, and as a component in machinery and vehicles.

4. **Load Distribution**:

- **Angle Stock**: Distributes load along the two legs, suitable for tension and compression applications.

- **U-Channel**: Distributes load across the web and flanges, ideal for supporting flat surfaces and edges.

5. **Fabrication and Installation**:

- **Angle Stock**: Easier to cut and weld due to its simpler shape.

- **U-Channel**: May require more complex fabrication techniques due to its shape.

6. **Cost**:

- **Angle Stock**: Generally less expensive due to simpler manufacturing processes.

- **U-Channel**: Can be more costly due to additional material and complexity.

7. **Versatility**:

- **Angle Stock**: More versatile for various applications due to its simple shape.

- **U-Channel**: More specialized, often used in specific applications requiring channeling or edging.

What are the common applications of carbon steel angle and U-channel?

Carbon steel angle and U-channel are versatile structural components used in various industries due to their strength, durability, and cost-effectiveness. Here are their common applications:

1. **Construction**: Both carbon steel angle and U-channel are extensively used in construction for framing, supports, and reinforcements. They provide structural integrity in buildings, bridges, and other infrastructure projects.

2. **Manufacturing**: In manufacturing, these components are used to create frames and supports for machinery and equipment. Their ability to withstand heavy loads makes them ideal for industrial applications.

3. **Automotive Industry**: Carbon steel angles and U-channels are used in the automotive industry for chassis construction, body frames, and other structural parts due to their strength and ability to absorb impact.

4. **Transportation**: They are used in the construction of trailers, railcars, and shipping containers, providing the necessary support and stability for transporting goods.

5. **Furniture**: In furniture manufacturing, these components are used for creating frames and supports for tables, chairs, and shelving units, offering both strength and aesthetic appeal.

6. **Agriculture**: In agricultural equipment, carbon steel angles and U-channels are used for constructing frames and supports for machinery, ensuring durability and longevity in harsh environments.

7. **Energy Sector**: They are used in the energy sector for constructing supports and frames for solar panels, wind turbines, and other energy infrastructure.

8. **Signage and Fencing**: These components are used in the construction of signs, billboards, and fencing, providing stability and resistance to environmental factors.

9. **DIY Projects**: Due to their availability and ease of use, carbon steel angles and U-channels are popular in DIY projects for creating custom structures and supports.

Overall, the versatility and strength of carbon steel angle and U-channel make them essential in numerous applications across different industries.

How do you determine the appropriate size for carbon steel angle and U-channel?

To determine the appropriate size for carbon steel angle and U-channel, consider the following factors:

1. **Load Requirements**: Calculate the load the structure will bear, including static and dynamic loads. This helps in selecting a size that can support the weight without bending or failing.

2. **Span Length**: Measure the distance the angle or U-channel needs to cover. Longer spans may require larger sizes to prevent sagging.

3. **Material Properties**: Consider the yield strength and tensile strength of the carbon steel. Higher strength materials may allow for smaller sizes.

4. **Design Standards**: Refer to relevant engineering standards and codes (e.g., AISC, ASTM) that provide guidelines on dimensions and load capacities for structural steel components.

5. **Deflection Criteria**: Determine acceptable deflection limits for the application. Ensure the selected size meets these criteria under expected loads.

6. **Connection Details**: Consider how the angle or U-channel will be connected to other components. This may influence the size due to bolt hole placement or welding requirements.

7. **Environmental Conditions**: Assess exposure to elements like moisture, chemicals, or temperature variations, which might necessitate a larger size for durability.

8. **Fabrication and Installation**: Evaluate ease of handling, cutting, and installation. Larger sizes may be more challenging to work with.

9. **Cost and Availability**: Balance the need for a specific size with budget constraints and availability from suppliers.

10. **Safety Factors**: Apply appropriate safety factors to account for uncertainties in load estimations and material properties.

By considering these factors, you can select a carbon steel angle or U-channel size that meets structural and functional requirements efficiently.

What are the benefits of using carbon steel for structural applications?

Carbon steel offers several benefits for structural applications:

1. **Strength and Durability**: Carbon steel is known for its high strength, making it ideal for supporting heavy loads and withstanding stress. Its durability ensures long-lasting performance in various environmental conditions.

2. **Cost-Effectiveness**: Compared to other metals like stainless steel or aluminum, carbon steel is more affordable. This cost-effectiveness makes it a popular choice for large-scale construction projects.

3. **Versatility**: Carbon steel can be easily molded into different shapes and sizes, allowing for a wide range of structural applications. It can be used in beams, columns, and other structural components.

4. **Weldability**: Carbon steel is highly weldable, which simplifies the construction process. It can be easily joined with other steel components, ensuring strong and reliable connections.

5. **Availability**: As one of the most commonly used materials in construction, carbon steel is readily available, ensuring that projects can proceed without delays due to material shortages.

6. **Recyclability**: Carbon steel is 100% recyclable, making it an environmentally friendly option. It can be reused in new projects, reducing waste and conserving resources.

7. **Resistance to Wear and Tear**: Carbon steel exhibits good resistance to wear and tear, which is crucial for structures exposed to constant use and movement.

8. **Thermal Conductivity**: Its thermal conductivity makes carbon steel suitable for applications where heat distribution is necessary, such as in building frameworks that require fire resistance.

9. **Corrosion Resistance**: While not as corrosion-resistant as stainless steel, carbon steel can be treated with coatings or galvanization to enhance its resistance to rust and corrosion, extending its lifespan in outdoor or moist environments.

How does the carbon content affect the properties of steel angles and channels?

The carbon content in steel significantly influences its properties, affecting both mechanical characteristics and usability. In steel angles and channels, which are structural components, the carbon content determines key attributes such as strength, ductility, hardness, and weldability.

1. **Strength and Hardness**: Higher carbon content increases the strength and hardness of steel. This is due to the formation of iron carbide, which enhances the steel's ability to withstand stress and resist deformation. Consequently, steel angles and channels with higher carbon content are more suitable for applications requiring high load-bearing capacity.

2. **Ductility and Toughness**: As carbon content increases, ductility and toughness generally decrease. Steel becomes less malleable and more brittle, which can be a disadvantage in applications where flexibility and impact resistance are crucial. Lower carbon steels are preferred for structures that need to absorb energy without fracturing.

3. **Weldability**: Higher carbon content reduces weldability. Steel with high carbon content is prone to cracking during welding due to the formation of hard and brittle microstructures. For construction purposes, where welding is often required, low to medium carbon steels are typically used to ensure ease of fabrication and structural integrity.

4. **Machinability**: Carbon content also affects machinability. Medium carbon steels offer a balance between hardness and machinability, making them suitable for manufacturing processes that require cutting or shaping.

5. **Corrosion Resistance**: While carbon content itself does not directly affect corrosion resistance, higher carbon steels are often alloyed with other elements to improve this property. However, increased carbon can lead to the formation of carbides that may reduce the effectiveness of protective coatings.

In summary, the carbon content in steel angles and channels must be carefully selected based on the specific requirements of strength, ductility, weldability, and machinability for their intended application.

What are the standard grades available for carbon steel angles and U-channels?

Carbon steel angles and U-channels are typically available in several standard grades, each with specific properties suited for various applications. The most common grades include:

1. **ASTM A36**: This is the most widely used carbon steel grade for angles and U-channels. It offers good weldability, machinability, and can be heat treated to harden its surface. It is suitable for construction and structural applications.

2. **ASTM A572**: Available in multiple grades (42, 50, 55, 60, 65), this high-strength, low-alloy steel is used in applications requiring increased strength and reduced weight. Grade 50 is the most common for angles and channels.

3. **ASTM A588**: Known for its corrosion resistance, this weathering steel is used in environments where exposure to the elements is a concern. It forms a protective rust layer, reducing the need for painting.

4. **ASTM A992**: Primarily used for structural shapes, this grade offers improved weldability and is often used in building frames and bridges.

5. **ASTM A529**: Available in grades 50 and 55, this high-strength carbon-manganese steel is used in structural applications where strength is a primary concern.

6. **ASTM A709**: Used in bridge construction, this grade offers high strength and corrosion resistance, with several sub-grades available for different environmental conditions.

7. **ASTM A500**: Commonly used for hollow structural sections, this grade is also applicable for angles and channels, offering good weldability and strength.

8. **ASTM A709**: Used in bridge construction, this grade offers high strength and corrosion resistance, with several sub-grades available for different environmental conditions.

These grades ensure that carbon steel angles and U-channels meet the necessary mechanical and chemical requirements for their intended applications.

How do you cut and weld carbon steel angle and U-channel?

To cut and weld carbon steel angle and U-channel, follow these steps:

1. **Cutting:**

- **Tools:** Use a metal cutting saw, angle grinder with a cut-off wheel, or a plasma cutter.

- **Preparation:** Secure the steel piece on a stable workbench using clamps. Mark the cutting line with a scribe or chalk.

- **Cutting Process:**

- For a metal cutting saw, align the blade with the marked line and cut steadily.

- With an angle grinder, position the cut-off wheel on the line and apply consistent pressure.

- For a plasma cutter, set the correct amperage, hold the torch at a 90-degree angle, and move along the line smoothly.

- **Safety:** Wear safety goggles, gloves, and protective clothing. Ensure proper ventilation.

2. **Welding:**

- **Tools:** Use a MIG, TIG, or stick welder depending on the thickness and requirements.

- **Preparation:** Clean the edges to be welded using a wire brush or grinder to remove rust, paint, or oil. Align the pieces using clamps or a jig.

- **Welding Process:**

- **MIG Welding:** Set the correct voltage and wire speed. Use a push or pull technique, maintaining a steady hand.

- **TIG Welding:** Use a tungsten electrode and filler rod. Maintain a short arc length and steady hand movement.

- **Stick Welding:** Select the appropriate electrode. Strike an arc and maintain a consistent travel speed.

- **Post-Weld:** Allow the weld to cool slowly. Inspect for defects and grind smooth if necessary.

3. **Safety:** Always wear a welding helmet, gloves, and protective clothing. Ensure proper ventilation and fire safety measures.