Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Raw Materials

- Metals

- Aluminum

- Aluminum Sheets Plates

.....Read More

Frequently Asked Questions

What are the common uses of aluminum sheets and plates?

Aluminum sheets and plates are versatile materials used across various industries due to their lightweight, corrosion resistance, and excellent strength-to-weight ratio. Common uses include:

1. **Aerospace Industry**: Aluminum sheets and plates are crucial in manufacturing aircraft structures, including fuselages, wings, and other components, due to their lightweight and high strength.

2. **Automotive Industry**: Used in car bodies, panels, and engine components to reduce weight and improve fuel efficiency while maintaining structural integrity.

3. **Construction**: Employed in roofing, cladding, and facades for buildings, offering durability and resistance to weathering. They are also used in structural applications like bridges and scaffolding.

4. **Packaging**: Aluminum sheets are used in the production of cans, foils, and other packaging materials due to their non-toxic nature and ability to preserve contents.

5. **Marine Industry**: Utilized in boat and shipbuilding for hulls and superstructures, providing resistance to corrosion in marine environments.

6. **Electrical Applications**: Used in electrical enclosures, bus bars, and heat sinks due to their excellent conductivity and thermal properties.

7. **Consumer Goods**: Found in household appliances, cookware, and electronics, offering a combination of aesthetic appeal and functionality.

8. **Signage and Display**: Aluminum sheets are used for signs, billboards, and display panels due to their ease of fabrication and weather resistance.

9. **Industrial Equipment**: Used in manufacturing machinery, storage tanks, and pressure vessels, providing strength and resistance to corrosion.

10. **Transportation**: Employed in railway cars, trucks, and trailers to reduce weight and improve fuel efficiency.

These applications highlight aluminum sheets and plates' adaptability and essential role in modern manufacturing and construction.

How do you cut aluminum sheets and plates?

To cut aluminum sheets and plates, you can use several methods depending on the thickness and precision required:

1. **Shearing**: Ideal for straight cuts on thin sheets. A guillotine shear or bench shear can be used for quick, clean cuts.

2. **Hand Tools**: For thin sheets, tin snips or aviation snips are effective for small, precise cuts. They come in straight, left, and right-cut versions.

3. **Power Saws**: Circular saws with carbide-tipped blades are suitable for thicker plates. Ensure the blade is designed for non-ferrous metals. Use a lubricant to reduce heat and prevent the blade from binding.

4. **Jigsaws**: Equipped with metal-cutting blades, jigsaws are versatile for curved or intricate cuts. Use a slow speed and apply lubricant to prevent overheating.

5. **Band Saws**: For thicker plates, a band saw with a metal-cutting blade provides smooth, precise cuts. Adjust the speed and feed rate according to the material thickness.

6. **Plasma Cutting**: Suitable for thick plates, plasma cutters use a high-velocity jet of ionized gas to melt and blow away the metal. It offers precision and speed but requires proper ventilation and safety gear.

7. **Water Jet Cutting**: This method uses a high-pressure stream of water mixed with abrasive particles. It provides precise cuts without heat distortion, suitable for complex shapes and thick materials.

8. **Laser Cutting**: Best for thin sheets, laser cutting offers high precision and clean edges. It is ideal for intricate designs but may not be cost-effective for thicker plates.

9. **CNC Machining**: For high precision and repeatability, CNC machines can be programmed to cut complex shapes in both sheets and plates.

Always wear appropriate safety gear, such as gloves and eye protection, and ensure proper ventilation when cutting aluminum.

What is the difference between aluminum sheets and plates?

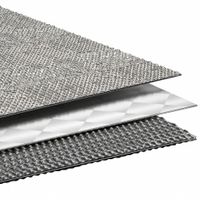

The primary difference between aluminum sheets and plates lies in their thickness. Aluminum sheets are thinner, typically ranging from 0.2 mm to 6 mm in thickness. They are often used in applications where flexibility and lightweight properties are essential, such as in automotive panels, roofing, and packaging. Sheets can be easily bent or cut to fit specific needs and are often supplied in large rolls or flat pieces.

Aluminum plates, on the other hand, are thicker, generally starting from 6 mm and going up to several inches. Plates are used in applications requiring more structural strength and durability, such as in aerospace, military, and heavy machinery. They are often used for structural components, tooling, and in the construction of ships and bridges.

The manufacturing processes for sheets and plates also differ. Sheets are typically produced through a rolling process that involves passing aluminum through a series of rollers to achieve the desired thickness. Plates are often produced through a similar rolling process but may also involve additional steps like heat treatment to enhance strength and durability.

In summary, the key difference is thickness, which dictates their respective applications and manufacturing processes. Sheets are thinner and more flexible, suitable for lightweight applications, while plates are thicker and stronger, used in heavy-duty and structural applications.

How do you prevent aluminum sheets from corroding?

To prevent aluminum sheets from corroding, consider the following methods:

1. **Anodizing**: This electrochemical process thickens the natural oxide layer on the aluminum surface, enhancing its resistance to corrosion and wear.

2. **Coating**: Apply protective coatings such as paint, powder coating, or specialized corrosion-resistant coatings to create a barrier against environmental elements.

3. **Alloying**: Use aluminum alloys that contain elements like magnesium, silicon, or zinc, which improve corrosion resistance.

4. **Cathodic Protection**: Employ sacrificial anodes made of a more reactive metal, such as zinc or magnesium, to protect aluminum sheets in corrosive environments.

5. **Sealing**: After anodizing, seal the aluminum surface to close the pores and enhance corrosion resistance.

6. **Regular Cleaning**: Clean aluminum sheets regularly to remove contaminants like dirt, salt, and pollutants that can accelerate corrosion.

7. **Environmental Control**: Store and use aluminum sheets in environments with controlled humidity and temperature to minimize exposure to corrosive elements.

8. **Use of Corrosion Inhibitors**: Apply chemical inhibitors that form a protective film on the aluminum surface, reducing the rate of corrosion.

9. **Avoid Galvanic Corrosion**: Prevent contact with dissimilar metals in the presence of an electrolyte to avoid galvanic corrosion.

10. **Proper Design**: Design structures to avoid water traps and ensure proper drainage, reducing prolonged exposure to moisture.

Implementing these strategies can significantly extend the lifespan of aluminum sheets by minimizing the risk of corrosion.

What are the thickness options available for aluminum sheets and plates?

Aluminum sheets and plates are available in a wide range of thicknesses to suit various applications. The thickness is typically measured in inches, millimeters, or gauge. Here are the common thickness options:

1. **Foil**: Less than 0.006 inches (0.15 mm). Used for packaging, insulation, and decorative purposes.

2. **Sheet**: Ranges from 0.006 inches (0.15 mm) to 0.249 inches (6.32 mm). Commonly used in automotive, aerospace, and construction industries.

3. **Plate**: 0.250 inches (6.35 mm) and above. Used in heavy-duty applications like shipbuilding, military vehicles, and industrial machinery.

4. **Gauge System**: In the gauge system, the thickness is inversely related to the gauge number. For example, a higher gauge number indicates a thinner sheet. Common gauges for aluminum sheets range from 7 gauge (0.1443 inches or 3.665 mm) to 30 gauge (0.0120 inches or 0.3048 mm).

These thickness options allow for versatility in applications, from lightweight and flexible uses to robust and structural needs.

How do you clean and maintain aluminum sheets and plates?

To clean and maintain aluminum sheets and plates, follow these steps:

1. **Initial Rinse**: Use a hose or pressure washer to remove loose dirt and debris.

2. **Cleaning Solution**: Mix mild dish soap with warm water. Avoid harsh chemicals or abrasive cleaners that can damage the aluminum.

3. **Scrubbing**: Use a soft cloth or non-abrasive sponge to gently scrub the surface. For stubborn stains, a soft-bristled brush can be used.

4. **Rinse Thoroughly**: Rinse the aluminum with clean water to remove all soap residues.

5. **Drying**: Use a soft, dry cloth to wipe the surface dry to prevent water spots and streaks.

6. **Polishing (Optional)**: For a shiny finish, apply a non-abrasive aluminum polish with a clean cloth, following the product instructions.

7. **Protection**: Consider applying a protective wax or sealant to prevent oxidation and corrosion.

8. **Regular Maintenance**: Regularly inspect for signs of corrosion or damage. Clean as needed to maintain appearance and integrity.

9. **Storage**: Store aluminum sheets and plates in a dry, covered area to protect them from moisture and environmental elements.

10. **Avoid Contact with Dissimilar Metals**: Prevent galvanic corrosion by ensuring aluminum does not come into contact with other metals.

By following these steps, you can effectively clean and maintain aluminum sheets and plates, ensuring their longevity and appearance.

What are the benefits of using aluminum sheets and plates over other materials?

Aluminum sheets and plates offer several advantages over other materials:

1. **Lightweight**: Aluminum is significantly lighter than steel, reducing transportation and handling costs and making it ideal for applications where weight is a critical factor, such as in aerospace and automotive industries.

2. **Corrosion Resistance**: Aluminum naturally forms a protective oxide layer, making it highly resistant to corrosion and ideal for use in environments exposed to moisture and chemicals, such as marine and outdoor applications.

3. **Strength-to-Weight Ratio**: Aluminum provides a high strength-to-weight ratio, offering sufficient strength while maintaining a lower weight compared to many other metals, which is beneficial in structural applications.

4. **Malleability and Ductility**: Aluminum can be easily formed into various shapes and sizes, allowing for versatile design options and ease of fabrication in manufacturing processes.

5. **Thermal and Electrical Conductivity**: Aluminum is an excellent conductor of heat and electricity, making it suitable for use in heat exchangers, electrical components, and other applications requiring efficient thermal or electrical transfer.

6. **Recyclability**: Aluminum is 100% recyclable without loss of properties, making it an environmentally friendly choice that supports sustainability and reduces the carbon footprint.

7. **Non-Magnetic**: Aluminum is non-magnetic, which is advantageous in applications where magnetic interference needs to be minimized, such as in electronic enclosures and certain aerospace components.

8. **Aesthetic Appeal**: Aluminum can be anodized or finished in various ways to enhance its appearance, making it suitable for architectural applications where aesthetics are important.

9. **Cost-Effectiveness**: While the initial cost may be higher than some materials, the long-term benefits such as durability, low maintenance, and recyclability can make aluminum a cost-effective choice over time.