Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Raw Materials

- Metals

- Aluminum

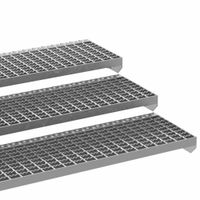

- Aluminum Grating Stair Treads

.....Read More

Frequently Asked Questions

What is aluminum grating used for?

Aluminum grating is used in a variety of applications due to its lightweight, corrosion-resistant, and durable properties. It is commonly employed in industrial and commercial settings for flooring, walkways, and platforms, providing a safe and sturdy surface that can withstand heavy loads while allowing for drainage and airflow. This makes it ideal for environments where moisture or debris accumulation is a concern, such as in factories, refineries, and offshore platforms.

In architectural applications, aluminum grating is used for decorative facades, sunshades, and ventilation grilles, offering both aesthetic appeal and functional benefits. Its ability to be fabricated into various shapes and sizes allows for creative design solutions while maintaining structural integrity.

In transportation, aluminum grating is utilized in the construction of bridges, ramps, and stair treads, where its non-slip surface enhances safety. It is also used in the manufacturing of vehicle components, such as truck beds and trailers, due to its strength-to-weight ratio, which contributes to fuel efficiency.

Additionally, aluminum grating is employed in the marine industry for ship decks and docks, where its resistance to saltwater corrosion is particularly advantageous. In the food and beverage industry, it is used in processing plants for its hygienic properties and ease of cleaning.

Overall, aluminum grating is a versatile material that serves multiple purposes across different sectors, providing a combination of safety, durability, and aesthetic value.

How is aluminum grating installed?

1. **Preparation**: Ensure the installation area is clean and level. Measure the space to determine the size and number of grating panels required.

2. **Support Structure**: Install a support structure, such as beams or frames, to hold the grating. These should be made of materials compatible with aluminum, like stainless steel or aluminum, to prevent galvanic corrosion.

3. **Cutting**: If necessary, cut the aluminum grating panels to fit the installation area using a saw with a blade suitable for aluminum. Ensure cuts are clean and smooth to prevent injury and ensure a proper fit.

4. **Positioning**: Place the grating panels onto the support structure. Ensure they are aligned correctly and fit snugly without excessive gaps.

5. **Fastening**: Secure the grating panels using appropriate fasteners, such as clips or bolts. Clips are often used for ease of installation and removal. Ensure fasteners are made of compatible materials to prevent corrosion.

6. **Alignment and Leveling**: Check that the grating is level and properly aligned. Adjust as necessary to ensure a stable and even surface.

7. **Safety Checks**: Inspect the installation for any sharp edges or protrusions that could cause injury. Ensure all fasteners are tight and secure.

8. **Final Inspection**: Conduct a final inspection to ensure the grating is securely installed and meets all safety and design specifications.

9. **Maintenance**: Regularly inspect the grating for signs of wear or damage. Clean and maintain as needed to ensure longevity and safety.

What are the benefits of aluminum grating?

Aluminum grating offers several benefits, making it a popular choice in various industrial and architectural applications. Firstly, its lightweight nature facilitates easy handling and installation, reducing labor costs and time. Despite its lightness, aluminum grating is strong and durable, providing excellent load-bearing capacity and resistance to impact, which is crucial for safety in high-traffic areas.

Corrosion resistance is another significant advantage. Aluminum naturally forms a protective oxide layer that prevents rust, making it ideal for outdoor and marine environments where exposure to moisture and chemicals is common. This property extends the lifespan of the grating and reduces maintenance costs.

Aluminum grating is also highly versatile, available in various styles, sizes, and finishes to suit different functional and aesthetic requirements. It can be used in flooring, walkways, platforms, and ventilation grilles, among other applications. Its non-sparking nature makes it suitable for use in explosive environments, enhancing safety.

Additionally, aluminum is a sustainable material. It is 100% recyclable without loss of properties, supporting eco-friendly construction practices. The recyclability of aluminum grating contributes to reduced environmental impact and aligns with green building standards.

The material's thermal and electrical conductivity can be advantageous in specific applications, such as heat dissipation in industrial settings. Furthermore, aluminum grating is non-magnetic, which is beneficial in applications where magnetic interference must be minimized.

Overall, aluminum grating combines strength, durability, and versatility with environmental benefits, making it a cost-effective and reliable choice for a wide range of applications.

How do you maintain aluminum grating?

To maintain aluminum grating, follow these steps:

1. **Regular Cleaning**: Clean the grating regularly to prevent the buildup of dirt, debris, and corrosive substances. Use a mild detergent mixed with water and a soft-bristle brush or sponge to scrub the surface. Rinse thoroughly with clean water to remove any soap residue.

2. **Inspection**: Conduct routine inspections to check for signs of damage, such as cracks, bends, or corrosion. Pay special attention to areas that are frequently exposed to harsh conditions or heavy loads.

3. **Corrosion Prevention**: Although aluminum is naturally resistant to corrosion, exposure to certain chemicals or environments can cause deterioration. Apply a protective coating or sealant if the grating is used in a highly corrosive environment.

4. **Repair and Replacement**: Promptly repair any minor damages to prevent them from worsening. For significant damage, consider replacing the affected sections to maintain structural integrity and safety.

5. **Avoid Harsh Chemicals**: Do not use harsh chemicals or abrasive materials for cleaning, as they can damage the aluminum surface. Stick to pH-neutral cleaners and avoid using steel wool or metal brushes.

6. **Lubrication**: If the grating includes moving parts, such as hinges or joints, lubricate them regularly with a suitable lubricant to ensure smooth operation and prevent wear.

7. **Environmental Considerations**: Protect the grating from extreme environmental conditions when possible. For instance, in areas with heavy snowfall, remove snow promptly to prevent excessive weight and potential damage.

8. **Secure Fastenings**: Check and tighten any bolts, screws, or fasteners to ensure the grating remains securely in place and does not pose a safety hazard.

By following these maintenance practices, you can extend the lifespan of aluminum grating and ensure it remains safe and functional.

What sizes are available for aluminum grating?

Aluminum grating is available in a variety of sizes to accommodate different applications and load requirements. The sizes can vary based on the type of grating, such as bar grating, plank grating, or expanded grating.

1. **Bar Grating**:

- **Bearing Bar Sizes**: Typically range from 1 inch to 3 inches in height, with thicknesses from 1/8 inch to 1/4 inch.

- **Spacing**: Common spacing for bearing bars is 1-3/16 inches, 15/16 inches, or 11/16 inches center-to-center.

- **Panel Sizes**: Standard panel sizes are often 2 feet by 20 feet or 3 feet by 24 feet, but custom sizes can be fabricated.

2. **Plank Grating**:

- **Width**: Usually available in widths of 6 inches, 9 inches, or 12 inches.

- **Height**: Heights can range from 1 inch to 2-1/2 inches.

- **Length**: Standard lengths are typically 10 feet or 12 feet, but custom lengths can be ordered.

3. **Expanded Grating**:

- **Mesh Size**: The diamond-shaped openings can vary, with common sizes being 1.5 inches by 0.75 inches or 2 inches by 1 inch.

- **Thickness**: Ranges from 0.125 inches to 0.25 inches.

- **Sheet Size**: Standard sheet sizes are often 4 feet by 8 feet or 4 feet by 10 feet.

These sizes can be customized based on specific project requirements, and manufacturers may offer additional options for finishes and coatings to enhance durability and appearance.

How does aluminum grating compare to steel grating?

Aluminum grating and steel grating are both popular choices for industrial and commercial applications, but they differ in several key aspects:

1. **Weight**: Aluminum grating is significantly lighter than steel grating. This makes it easier to handle, transport, and install, reducing labor costs and time.

2. **Corrosion Resistance**: Aluminum has excellent corrosion resistance, especially in environments exposed to moisture or chemicals. Steel, unless galvanized or stainless, is prone to rust and corrosion, requiring additional coatings or treatments for protection.

3. **Strength**: Steel grating is generally stronger and more durable than aluminum, making it suitable for applications requiring high load-bearing capacity. However, aluminum can still provide adequate strength for many applications, especially when weight savings are a priority.

4. **Cost**: Steel grating is typically less expensive than aluminum grating. However, the total cost of ownership may be lower for aluminum due to its corrosion resistance and lower maintenance requirements.

5. **Maintenance**: Aluminum grating requires less maintenance due to its natural resistance to corrosion. Steel grating may need regular inspections and maintenance to prevent rust and ensure longevity.

6. **Aesthetic Appeal**: Aluminum grating often has a more modern and sleek appearance, which can be advantageous for architectural applications. Steel can be more industrial in appearance unless treated or coated.

7. **Thermal Conductivity**: Aluminum has higher thermal conductivity than steel, which can be beneficial or detrimental depending on the application, such as in heat dissipation or insulation scenarios.

8. **Recyclability**: Both materials are recyclable, but aluminum is often more valued in recycling markets due to its higher energy savings during the recycling process.

In summary, the choice between aluminum and steel grating depends on factors like weight, corrosion resistance, strength, cost, and specific application requirements.

Where can I buy aluminum grating?

You can buy aluminum grating from a variety of sources, including:

1. **Specialty Metal Suppliers**: Companies like McNICHOLS, Direct Metals, and Marco Specialty Steel specialize in metal products, including aluminum grating. They offer a wide range of grating options and can often provide custom solutions.

2. **Industrial Supply Companies**: Large industrial suppliers such as Grainger, Fastenal, and MSC Industrial Supply carry aluminum grating. These companies often have extensive catalogs and can provide quick shipping for standard sizes.

3. **Online Marketplaces**: Websites like Amazon and eBay sometimes have listings for aluminum grating, especially for smaller projects or DIY purposes. However, availability and variety might be limited compared to specialized suppliers.

4. **Local Metal Fabricators**: Many local metal fabrication shops can either supply aluminum grating or order it for you. This option is particularly useful if you need custom sizes or specific fabrication services.

5. **Construction Material Suppliers**: Companies that supply materials for construction projects, such as Metal Supermarkets, often carry aluminum grating. They can be a good resource for both standard and custom orders.

6. **Direct from Manufacturers**: Some manufacturers sell directly to consumers or businesses. Companies like Nucor Grating and Ohio Gratings Inc. may offer direct sales or can direct you to a distributor.

7. **Online Metal Retailers**: Websites like OnlineMetals.com and MetalsDepot.com offer a variety of metal products, including aluminum grating, with the convenience of online ordering and delivery.

When purchasing, consider factors such as the type of grating (e.g., bar, plank, expanded), load requirements, and environmental conditions to ensure you select the right product for your needs.