Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Raw Materials

- Metals

- Aluminum

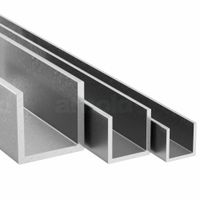

- Aluminum Angles Channels

.....Read More

Frequently Asked Questions

What are the common uses of aluminum angles and channels?

Aluminum angles and channels are versatile structural components used in various industries due to their strength, lightweight nature, and resistance to corrosion. Common uses include:

1. **Construction and Architecture**: Aluminum angles and channels are used in framing, supports, and structural reinforcements. They are ideal for window frames, door frames, and curtain walls due to their aesthetic appeal and durability.

2. **Transportation**: In the automotive and aerospace industries, these components are used for manufacturing vehicle frames, supports, and panels. Their lightweight properties contribute to fuel efficiency and performance.

3. **Manufacturing and Fabrication**: Aluminum angles and channels serve as essential components in machinery, equipment, and assembly lines. They provide structural support and are used in the fabrication of racks, shelves, and workstations.

4. **Electrical and Electronics**: These components are used in the construction of enclosures, housings, and supports for electrical equipment. Their non-magnetic properties make them suitable for sensitive electronic applications.

5. **Marine Applications**: Due to their corrosion resistance, aluminum angles and channels are used in boat building and marine structures, including docks, gangways, and ladders.

6. **Signage and Display**: They are used in the construction of sign frames, display stands, and exhibition booths, offering a combination of strength and lightweight properties.

7. **HVAC Systems**: Aluminum channels are used in ductwork and ventilation systems due to their ability to withstand environmental conditions and ease of installation.

8. **Furniture and Interior Design**: These components are used in the design of modern furniture, fixtures, and interior elements, providing a sleek and contemporary look.

Overall, aluminum angles and channels are integral to various applications, offering a balance of strength, weight, and resistance to environmental factors.

How do you cut aluminum angles and channels?

To cut aluminum angles and channels, follow these steps:

1. **Select the Right Tools**: Use a miter saw with a carbide-tipped blade designed for cutting non-ferrous metals. Alternatively, a hacksaw with a fine-toothed blade or a jigsaw with a metal-cutting blade can be used for smaller or thinner pieces.

2. **Measure and Mark**: Use a tape measure to determine the length needed. Mark the cut line clearly with a pencil or a scribe for precision.

3. **Secure the Material**: Clamp the aluminum securely to a workbench or a stable surface to prevent movement during cutting. Use a vice or C-clamps to hold it in place.

4. **Set Up the Saw**: If using a miter saw, adjust the angle and depth settings as needed. Ensure the blade is sharp and properly aligned.

5. **Safety Precautions**: Wear safety goggles, gloves, and ear protection. Ensure the work area is clear of obstructions.

6. **Cutting Process**:

- For a miter saw, align the blade with the marked line, start the saw, and slowly lower the blade through the aluminum.

- For a hacksaw, use steady, even strokes along the marked line.

- For a jigsaw, guide the blade along the line with a slow, steady motion.

7. **Finishing Touches**: After cutting, use a file or sandpaper to smooth any rough edges or burrs.

8. **Clean Up**: Remove any metal shavings from the work area to prevent injury or damage.

By following these steps, you can achieve clean, precise cuts on aluminum angles and channels.

What are the differences between aluminum angles and channels?

Aluminum angles and channels are both structural components used in construction and manufacturing, but they differ in shape, application, and properties.

1. **Shape**:

- **Aluminum Angles**: These have an "L" shape with two legs that meet at a right angle. The legs can be of equal or unequal length.

- **Aluminum Channels**: These have a "C" or "U" shape with a flat back and two parallel flanges or lips extending from the back.

2. **Applications**:

- **Aluminum Angles**: Commonly used for framing, bracing, and support applications. They are ideal for corner protection and can be used in various structural applications due to their right-angle design.

- **Aluminum Channels**: Often used for tracks, slides, and structural support. They are suitable for applications requiring a flat surface for mounting or sliding components.

3. **Load-Bearing Capacity**:

- **Aluminum Angles**: Provide good support for loads applied perpendicular to the axis of the angle. They are effective in applications where two-dimensional support is needed.

- **Aluminum Channels**: Offer better support for loads distributed along the length of the channel. They are more effective in applications requiring three-dimensional support.

4. **Installation**:

- **Aluminum Angles**: Easier to install in corners and edges due to their shape. They can be bolted, welded, or riveted into place.

- **Aluminum Channels**: Require more precise alignment for installation, especially when used as tracks or guides.

5. **Aesthetic and Design**:

- **Aluminum Angles**: Provide a clean, sharp look suitable for modern designs.

- **Aluminum Channels**: Offer a more robust appearance and can be used to conceal wiring or other components.

6. **Cost**:

- Generally, the cost can vary based on size, thickness, and alloy, but channels may be more expensive due to their larger material volume.

What grades of aluminum are used for angles and channels?

The most common grades of aluminum used for angles and channels are 6061 and 6063.

6061 aluminum is known for its strength, weldability, and corrosion resistance. It is often used in structural applications where strength is a priority. This grade is heat-treatable and offers good mechanical properties, making it suitable for heavy-duty structures, marine applications, and aerospace components.

6063 aluminum, on the other hand, is often referred to as an architectural alloy. It is known for its excellent finish and is more easily extruded than 6061. This makes it ideal for applications where aesthetics are important, such as window frames, door frames, and other architectural components. While it is not as strong as 6061, it offers good corrosion resistance and is also heat-treatable.

Both grades are widely used in the construction of angles and channels due to their versatility and favorable properties.

How do you join aluminum angles and channels?

To join aluminum angles and channels, you can use several methods depending on the application, strength requirements, and tools available:

1. **Welding**: Use TIG (Tungsten Inert Gas) welding for a strong, permanent bond. Clean the aluminum surfaces thoroughly to remove oxides and use a filler rod compatible with the aluminum alloy. Ensure proper heat control to prevent warping.

2. **Riveting**: Drill holes through the overlapping sections of the angles and channels. Insert rivets and use a rivet gun to secure them. This method is suitable for applications where welding is not feasible.

3. **Bolting**: Drill aligned holes in the pieces to be joined. Use bolts, nuts, and washers to fasten them together. This allows for disassembly if needed. Ensure the bolts are made of a compatible material to prevent galvanic corrosion.

4. **Adhesive Bonding**: Use a high-strength epoxy or structural adhesive designed for metal bonding. Clean the surfaces and apply the adhesive evenly. Clamp the pieces together until the adhesive cures. This method is useful for lightweight applications.

5. **Mechanical Fasteners**: Use brackets, clips, or custom-designed fasteners to join the angles and channels. This method is often used in modular or adjustable assemblies.

6. **Brazing/Soldering**: Use a low-temperature aluminum brazing rod and a torch. Clean the surfaces and apply flux to prevent oxidation. Heat the joint evenly and apply the brazing rod to form a bond. This method is less common due to the difficulty in controlling heat.

Choose the method based on the specific requirements of your project, considering factors like load-bearing capacity, environmental conditions, and the need for disassembly.

What are the benefits of using aluminum angles and channels?

Aluminum angles and channels offer several benefits, making them popular in various applications:

1. **Lightweight**: Aluminum is significantly lighter than steel, reducing the overall weight of structures and making it easier to handle and transport.

2. **Corrosion Resistance**: Aluminum naturally forms a protective oxide layer, making it highly resistant to corrosion and ideal for outdoor and marine environments.

3. **Strength-to-Weight Ratio**: Despite being lightweight, aluminum provides excellent strength, making it suitable for structural applications where weight is a concern.

4. **Versatility**: Aluminum angles and channels come in various sizes and thicknesses, allowing for flexibility in design and application across industries such as construction, automotive, and aerospace.

5. **Ease of Fabrication**: Aluminum is easy to cut, machine, and weld, facilitating quick and efficient fabrication processes.

6. **Aesthetic Appeal**: Aluminum has a modern, sleek appearance and can be anodized or painted for enhanced visual appeal, making it a popular choice in architectural applications.

7. **Recyclability**: Aluminum is 100% recyclable without loss of properties, making it an environmentally friendly option that supports sustainability efforts.

8. **Thermal Conductivity**: Aluminum has excellent thermal conductivity, beneficial in applications requiring heat dissipation, such as in heat sinks and cooling systems.

9. **Non-Magnetic**: Aluminum is non-magnetic, making it suitable for applications where magnetic interference needs to be minimized.

10. **Cost-Effective**: While the initial cost may be higher than some materials, the durability, low maintenance, and recyclability of aluminum can lead to cost savings over time.

These benefits make aluminum angles and channels a preferred choice for engineers and designers seeking a balance of performance, durability, and aesthetics.

How do you calculate the load capacity of aluminum angles and channels?

To calculate the load capacity of aluminum angles and channels, follow these steps:

1. **Determine Material Properties**: Identify the aluminum alloy and temper, then find its yield strength and modulus of elasticity from material property tables.

2. **Cross-Sectional Properties**: Calculate the moment of inertia (I) and section modulus (S) for the specific shape and size of the angle or channel. These can be found in engineering handbooks or calculated using geometric formulas.

3. **Loading Conditions**: Define the type of loading (e.g., point load, uniformly distributed load) and support conditions (e.g., simply supported, fixed).

4. **Calculate Bending Stress**: Use the formula:

\[

\sigma = \frac{M}{S}

\]

where \( \sigma \) is the bending stress, \( M \) is the maximum moment, and \( S \) is the section modulus.

5. **Check Against Yield Strength**: Ensure that the calculated bending stress does not exceed the yield strength of the material.

6. **Deflection Check**: Calculate deflection using:

\[

\delta = \frac{FL^3}{48EI}

\]

for a simply supported beam with a central point load, where \( F \) is the load, \( L \) is the length, \( E \) is the modulus of elasticity, and \( I \) is the moment of inertia. Ensure deflection is within acceptable limits.

7. **Factor of Safety**: Apply a factor of safety (typically between 1.5 and 3) to ensure reliability under unexpected conditions.

8. **Buckling Check**: For long, slender members, check for buckling using Euler's formula:

\[

P_{cr} = \frac{\pi^2EI}{(KL)^2}

\]

where \( P_{cr} \) is the critical load, and \( K \) is the column effective length factor.

By following these steps, you can determine the load capacity of aluminum angles and channels, ensuring they are safe and effective for their intended application.