Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

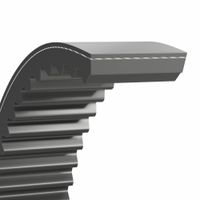

- Power Transmission

- Belts Pulleys

- V Belts

.....Read More

Frequently Asked Questions

What are the different types of V-belts and their applications?

V-belts are categorized based on their cross-sectional shape, size, and application. The main types include:

1. **Classical V-Belts**: These are the most common and are identified by their trapezoidal cross-section. They are used in industrial applications, agriculture, and automotive sectors for power transmission.

2. **Narrow V-Belts**: With a narrower profile, these belts offer higher power capacity and efficiency. They are suitable for high-speed and high-torque applications, such as in heavy machinery and industrial equipment.

3. **Wedge V-Belts**: These belts have a deeper wedge shape, providing better grip and higher power transmission capabilities. They are used in demanding applications like compressors, pumps, and heavy-duty machinery.

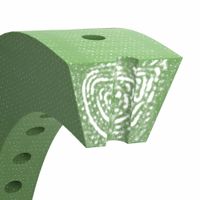

4. **Cogged V-Belts**: Featuring notches or cogs on the inner side, these belts offer flexibility and better heat dissipation. They are ideal for small pulley diameters and high-speed applications, such as in automotive engines and HVAC systems.

5. **Double V-Belts (Hexagonal Belts)**: These belts have a hexagonal cross-section, allowing them to drive pulleys on both sides. They are used in serpentine drives and agricultural machinery where multiple pulleys are involved.

6. **Variable Speed V-Belts**: Designed for variable speed applications, these belts can adjust to different speeds and loads. They are used in machinery requiring speed variation, such as in lathes and milling machines.

7. **Joined V-Belts**: Consisting of multiple V-belts joined together, these belts provide stability and prevent belt turnover. They are used in applications with pulsating loads, like in crushers and vibrating screens.

Each type of V-belt is designed to meet specific operational requirements, ensuring efficient power transmission and longevity in various mechanical systems.

How do I determine the correct size and length of a V-belt for my system?

To determine the correct size and length of a V-belt for your system, follow these steps:

1. **Identify Belt Type**: Determine the type of V-belt needed (e.g., classical, narrow, or fractional horsepower) based on the application and pulley design.

2. **Measure Pulley Diameters**: Measure the diameter of both the driver (small) and driven (large) pulleys. Use a caliper or a flexible tape measure for accuracy.

3. **Measure Center Distance**: Measure the distance between the centers of the two pulleys. This is crucial for calculating the belt length.

4. **Calculate Belt Length**: Use the formula for belt length:

\[

L = 2C + 1.57(D + d) + \frac{(D - d)^2}{4C}

\]

where \(L\) is the belt length, \(C\) is the center distance, \(D\) is the diameter of the larger pulley, and \(d\) is the diameter of the smaller pulley.

5. **Check Belt Width**: Ensure the belt width matches the pulley groove. The belt should sit flush with the top of the pulley groove without being too tight or too loose.

6. **Consider Belt Tension**: Ensure the belt has the correct tension. A belt that is too tight can cause excessive wear, while a loose belt can slip and reduce efficiency.

7. **Consult Manufacturer Specifications**: Refer to the equipment or belt manufacturer’s specifications for recommended belt sizes and types for your specific application.

8. **Use a Belt Sizing Tool**: If available, use a belt sizing tool or calculator provided by belt manufacturers for precise measurements.

9. **Trial Fit**: Once you have selected a belt, perform a trial fit to ensure it operates smoothly without slippage or excessive tension.

10. **Adjust as Necessary**: If the belt does not fit correctly, re-evaluate your measurements and calculations, and adjust accordingly.

What is the difference between standard and cogged V-belts?

Standard V-belts and cogged V-belts are both used in power transmission systems, but they have distinct differences:

1. **Design**:

- **Standard V-belts**: These belts have a continuous, smooth surface and a trapezoidal cross-section. They are made from rubber or synthetic materials with embedded tensile cords for strength.

- **Cogged V-belts**: These belts have notches or cogs on the inner side, which allow for greater flexibility and heat dissipation. The cogs are designed to fit into the grooves of the pulley.

2. **Flexibility**:

- **Standard V-belts**: Less flexible due to their solid construction, which can limit their use in applications with smaller pulley diameters.

- **Cogged V-belts**: More flexible because of the cogs, making them suitable for smaller pulley diameters and reducing bending stress.

3. **Efficiency**:

- **Standard V-belts**: Generally less efficient due to higher bending resistance and heat generation.

- **Cogged V-belts**: More efficient as the cogs reduce bending resistance and improve airflow, leading to less heat buildup and energy loss.

4. **Heat Dissipation**:

- **Standard V-belts**: Tend to retain more heat, which can lead to faster wear and reduced lifespan.

- **Cogged V-belts**: Better at dissipating heat due to increased surface area and airflow, enhancing durability.

5. **Applications**:

- **Standard V-belts**: Suitable for general-purpose applications where high flexibility and efficiency are not critical.

- **Cogged V-belts**: Ideal for high-performance applications requiring greater efficiency, flexibility, and heat resistance.

6. **Cost**:

- **Standard V-belts**: Typically less expensive due to simpler construction.

- **Cogged V-belts**: Often more costly but offer better performance and longevity in demanding applications.

How do I install and tension a V-belt properly?

1. **Safety First**: Ensure the machine is turned off and disconnected from the power source.

2. **Inspect Components**: Check pulleys for wear or damage. Ensure they are aligned and clean.

3. **Select the Correct Belt**: Use the manufacturer's specifications to choose the right V-belt size and type.

4. **Remove Old Belt**: Loosen the tensioning device or adjust the motor base to remove the old belt.

5. **Install New Belt**: Place the new V-belt over the pulleys. Ensure it sits properly in the pulley grooves.

6. **Align Pulleys**: Use a straight edge or laser alignment tool to ensure pulleys are aligned. Misalignment can cause premature wear.

7. **Tension the Belt**: Adjust the tensioning device or motor base to apply tension. The belt should have a slight deflection when pressed with moderate force. Refer to the manufacturer’s guidelines for the correct deflection or tension force.

8. **Check Tension**: Use a belt tension gauge to ensure the tension is within the recommended range. Adjust as necessary.

9. **Secure Components**: Tighten all bolts and fasteners to secure the motor or tensioning device in place.

10. **Test Run**: Reconnect the power and run the machine briefly. Observe the belt for proper operation and listen for unusual noises.

11. **Recheck Tension**: After a short run-in period, recheck the belt tension and adjust if necessary.

12. **Regular Maintenance**: Periodically inspect the belt for wear and re-tension as needed to ensure optimal performance and longevity.

What are the advantages of using link V-belts?

Link V-belts offer several advantages over traditional V-belts:

1. **Flexibility and Versatility**: Link V-belts are highly flexible and can be easily adjusted to fit various pulley sizes and configurations. This adaptability makes them suitable for a wide range of applications and allows for quick installation and replacement without the need for dismantling components.

2. **Reduced Vibration and Noise**: The design of link V-belts helps in dampening vibrations and reducing noise levels during operation. This results in smoother performance and less wear on machinery components, contributing to longer equipment life.

3. **Ease of Installation and Maintenance**: Unlike traditional V-belts, link V-belts can be installed without the need for special tools or equipment. They can be assembled and disassembled quickly, which simplifies maintenance and reduces downtime.

4. **Durability and Longevity**: Made from high-quality materials, link V-belts are resistant to oil, chemicals, and extreme temperatures. This enhances their durability and extends their service life, making them a cost-effective choice in the long run.

5. **Reduced Inventory Costs**: Since link V-belts can be adjusted to fit different sizes, they reduce the need to stock multiple belt sizes. This minimizes inventory costs and simplifies inventory management.

6. **Improved Efficiency**: The precise fit and reduced slippage of link V-belts lead to improved power transmission efficiency. This can result in energy savings and better overall performance of the machinery.

7. **Safety**: The ease of installation and removal reduces the risk of injury during maintenance. Additionally, the ability to quickly replace a damaged section of the belt without removing the entire belt enhances operational safety.

These advantages make link V-belts a preferred choice in various industrial and mechanical applications.

How do I maintain and troubleshoot V-belt drive systems?

To maintain and troubleshoot V-belt drive systems, follow these steps:

1. **Inspection**: Regularly inspect belts for wear, cracks, fraying, or glazing. Check pulleys for alignment and wear. Ensure the belt tension is correct; too tight can cause bearing wear, too loose can cause slippage.

2. **Alignment**: Ensure pulleys are properly aligned. Misalignment can cause uneven wear and reduce belt life. Use a straight edge or laser alignment tool to check.

3. **Tensioning**: Adjust belt tension according to manufacturer specifications. Use a tension gauge to ensure accuracy. Proper tension prevents slippage and extends belt life.

4. **Cleaning**: Keep belts and pulleys clean from oil, grease, and debris. Contaminants can cause slippage and premature wear.

5. **Lubrication**: Avoid lubricating belts as it can cause slippage. Ensure bearings and other components are properly lubricated to prevent overheating.

6. **Replacement**: Replace belts showing signs of wear or damage. Always replace belts in matched sets to ensure even tension and load distribution.

7. **Troubleshooting**:

- **Slippage**: Check tension and adjust if necessary. Inspect for oil or grease contamination.

- **Noise**: Squealing may indicate slippage or misalignment. Check tension and alignment.

- **Vibration**: Inspect for misalignment, worn pulleys, or damaged belts.

- **Overheating**: Ensure proper tension and alignment. Check for overloading or inadequate ventilation.

8. **Documentation**: Keep records of maintenance activities, including inspections, adjustments, and replacements. This helps in identifying patterns and planning preventive maintenance.

By following these steps, you can ensure the efficient operation and longevity of V-belt drive systems.

What are the signs of wear or failure in a V-belt?

Signs of wear or failure in a V-belt include:

1. **Cracking and Fraying**: Visible cracks or frayed edges on the belt indicate material degradation, often due to age, excessive heat, or improper tension.

2. **Glazing**: A shiny or glazed appearance on the belt surface suggests slippage, often caused by insufficient tension or misalignment, leading to overheating and hardening of the belt.

3. **Uneven Wear**: Uneven wear patterns, such as one side being more worn than the other, can indicate misalignment of pulleys or improper installation.

4. **Belt Slippage**: If the belt slips on the pulleys, it may be due to insufficient tension, wear, or contamination with oil or grease.

5. **Noise**: Squealing or chirping noises during operation can be a sign of slippage, misalignment, or improper tension.

6. **Belt Stretching**: Excessive stretching or elongation of the belt can lead to loss of tension and slippage, often due to overloading or material fatigue.

7. **Visible Damage**: Cuts, tears, or missing chunks from the belt indicate physical damage, possibly from foreign objects or improper handling.

8. **Pulley Wear**: Excessive wear on the pulleys can also indicate a problem with the belt, such as misalignment or incorrect tension.

9. **Vibration**: Increased vibration in the machinery can be a sign of belt wear or misalignment.

10. **Burn Marks**: Burn marks on the belt surface suggest overheating, often due to slippage or excessive friction.

11. **Loss of Tension**: Frequent need to retighten the belt indicates stretching or wear.

12. **Material Hardening**: A hardened or brittle belt is a sign of aging or exposure to high temperatures.

Regular inspection and maintenance are crucial to identify these signs early and prevent equipment failure.