Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Power Transmission

- Belts Pulleys

- Timing Belt Pulleys Idlers

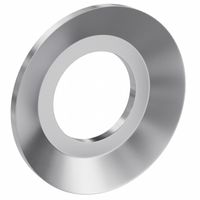

- Timing Belt Pulley Bar Stock Flanges

.....Read More

Frequently Asked Questions

What is timing belt pulley bar stock?

Timing belt pulley bar stock is a raw material used in the manufacturing of timing belt pulleys. These pulleys are essential components in mechanical systems, particularly in engines and machinery, where they synchronize the rotation of the crankshaft and camshaft to ensure proper timing of engine valves. The bar stock is typically made from materials like aluminum, steel, or plastic, chosen for their durability, strength, and resistance to wear.

The bar stock is produced in long cylindrical or rectangular shapes, allowing manufacturers to cut and machine it into specific pulley designs and sizes. This raw form provides flexibility in creating custom pulleys tailored to specific applications, whether for automotive engines, industrial machinery, or other mechanical systems.

The process of transforming bar stock into a finished pulley involves several machining operations, such as turning, milling, and drilling, to achieve the desired dimensions and features, including grooves or teeth that match the timing belt's profile. These grooves ensure a secure fit and efficient power transmission between the belt and the pulley.

Using bar stock for pulley production offers advantages like cost-effectiveness, as it allows for bulk purchasing and reduces waste by enabling precise cutting and shaping. Additionally, it provides the opportunity for manufacturers to maintain quality control over the material properties and dimensions, ensuring the final product meets specific performance and durability standards.

How do you cut timing belt pulley bar stock to the desired length?

To cut timing belt pulley bar stock to the desired length, follow these steps:

1. **Measure and Mark**: Use a caliper or measuring tape to determine the desired length of the pulley. Mark the cutting point on the bar stock with a scribe or marker for precision.

2. **Secure the Bar Stock**: Place the bar stock in a vise or a lathe chuck to hold it securely. Ensure it is tightly clamped to prevent movement during cutting.

3. **Select the Cutting Tool**: Choose an appropriate cutting tool based on the material of the bar stock. A bandsaw is commonly used for metal bar stock, while a hacksaw or a cutoff wheel can be used for smaller or softer materials.

4. **Cutting Process**:

- If using a bandsaw, align the marked point with the saw blade. Turn on the saw and gently guide the blade through the bar stock, applying steady pressure.

- For a hacksaw, position the blade on the marked line and use long, even strokes to cut through the material.

- If using a cutoff wheel, ensure the wheel is rated for the material. Align the wheel with the mark and cut through the stock with steady pressure.

5. **Deburring**: After cutting, the edges may be rough. Use a file, deburring tool, or sandpaper to smooth the cut edges and remove any burrs.

6. **Final Inspection**: Measure the cut piece to ensure it matches the desired length. Check for any imperfections or irregularities in the cut.

7. **Safety Precautions**: Always wear appropriate personal protective equipment (PPE) such as safety glasses and gloves during the cutting process to protect against metal shavings and sharp edges.

What materials are timing belt pulley bar stocks made from?

Timing belt pulley bar stocks are typically made from materials that offer a balance of strength, durability, and machinability. Common materials include:

1. **Aluminum**: Lightweight and corrosion-resistant, aluminum is often used for its ease of machining and good thermal conductivity. It is suitable for applications where weight reduction is crucial.

2. **Steel**: Known for its strength and durability, steel is used in applications requiring high load capacity and resistance to wear. It can be carbon steel or alloy steel, depending on the specific requirements.

3. **Stainless Steel**: Offers excellent corrosion resistance and is used in environments where exposure to moisture or chemicals is a concern. It is also strong and durable, making it suitable for demanding applications.

4. **Cast Iron**: Provides good wear resistance and vibration damping properties. It is often used in heavy-duty applications where these characteristics are beneficial.

5. **Plastic/Polymer**: Materials like nylon or acetal are used for lightweight applications where noise reduction and corrosion resistance are important. They are not as strong as metals but offer good wear resistance and low friction.

6. **Brass/Bronze**: These materials offer good machinability and corrosion resistance. They are used in applications where low friction and good wear properties are needed.

Each material is chosen based on the specific requirements of the application, such as load capacity, environmental conditions, and cost considerations.

How do timing belt pulley flanges work with bar stock?

Timing belt pulley flanges are designed to keep the timing belt aligned on the pulley, preventing it from slipping off during operation. When working with bar stock, which is raw material in the form of long bars, the process involves machining the bar stock to create the pulley with integrated or attached flanges.

The flanges are typically positioned on either side of the pulley. They act as barriers that guide the timing belt, ensuring it remains centered on the pulley grooves. This is crucial for maintaining the synchronization between the driving and driven components in a mechanical system.

To create a timing belt pulley with flanges from bar stock, the following steps are generally involved:

1. **Material Selection**: Choose a suitable bar stock material, such as aluminum, steel, or plastic, based on the application's strength, weight, and environmental requirements.

2. **Machining**: Use CNC machines or lathes to shape the bar stock into the desired pulley profile. This includes cutting the grooves that match the timing belt's teeth and forming the pulley’s outer diameter.

3. **Flange Formation**: The flanges can be machined directly from the bar stock as part of the pulley or attached separately. If separate, they are often press-fitted, welded, or bolted onto the pulley.

4. **Finishing**: The pulley and flanges are finished to ensure smooth surfaces, reducing friction and wear on the timing belt.

5. **Quality Control**: Inspect the pulley for dimensional accuracy and ensure the flanges are properly aligned and secured.

By integrating flanges with the pulley, the system achieves reliable belt tracking, reducing the risk of misalignment and potential mechanical failure.

What are the benefits of using timing belt pulley bar stock for custom applications?

Timing belt pulley bar stock offers several benefits for custom applications:

1. **Customization**: Bar stock allows for the creation of pulleys tailored to specific requirements, including unique sizes, shapes, and tooth profiles, ensuring compatibility with custom machinery.

2. **Material Variety**: Available in various materials such as aluminum, steel, and plastic, bar stock can be selected based on the application's strength, weight, and environmental conditions.

3. **Cost-Effectiveness**: Purchasing bar stock in bulk can be more economical than ordering custom pulleys individually, especially for small production runs or prototyping.

4. **Flexibility**: It provides the flexibility to modify designs quickly, accommodating changes in project specifications without the need for new tooling or molds.

5. **Reduced Lead Time**: Using bar stock can significantly reduce lead times, as it eliminates the need for waiting on custom orders from manufacturers.

6. **Precision**: Bar stock can be machined to high precision, ensuring accurate tooth profiles and alignment, which is crucial for maintaining the efficiency and longevity of timing belt systems.

7. **Prototyping and Testing**: Ideal for prototyping, bar stock allows engineers to test and refine designs before committing to mass production, reducing the risk of costly errors.

8. **Versatility**: Suitable for a wide range of applications, from automotive to industrial machinery, bar stock can be adapted to various operational demands.

9. **Durability**: High-quality bar stock ensures that the resulting pulleys are durable and capable of withstanding the stresses of operation, reducing maintenance and replacement costs.

10. **Innovation**: Encourages innovation by allowing designers to experiment with new configurations and materials, potentially leading to improved performance and efficiency.

Overall, timing belt pulley bar stock provides a versatile, cost-effective, and efficient solution for custom applications, enabling precise and tailored pulley production.

How do you select the right timing belt pulley flange for your application?

To select the right timing belt pulley flange for your application, consider the following factors:

1. **Belt Type and Size**: Ensure compatibility with the belt's width, pitch, and profile. The flange should match the belt's specifications to prevent slippage and ensure efficient power transmission.

2. **Material**: Choose a material that suits the operating environment. Common materials include aluminum for lightweight applications, steel for strength, and plastic for corrosion resistance.

3. **Load Requirements**: Assess the load the pulley will handle. Heavier loads may require flanges with higher strength and durability.

4. **Operating Environment**: Consider temperature, humidity, and exposure to chemicals. Select flanges that can withstand these conditions without degrading.

5. **Speed and Torque**: Ensure the flange can handle the system's speed and torque requirements. High-speed applications may need flanges with tighter tolerances.

6. **Alignment and Tracking**: Flanges help maintain belt alignment. Choose flanges that provide adequate guidance to prevent belt misalignment and ensure smooth operation.

7. **Installation and Maintenance**: Consider ease of installation and maintenance. Flanges that are easy to install and require minimal maintenance can reduce downtime.

8. **Cost**: Balance cost with performance requirements. While cheaper options may be tempting, they might not offer the durability or performance needed for demanding applications.

9. **Supplier Support**: Choose a reputable supplier who can provide technical support and ensure the availability of replacement parts.

10. **Customization**: If standard flanges do not meet your needs, consider custom options to fit specific application requirements.

By evaluating these factors, you can select a timing belt pulley flange that ensures optimal performance, longevity, and reliability for your specific application.

What are the common applications for timing belt pulley bar stock and flanges?

Timing belt pulley bar stock and flanges are commonly used in various applications across different industries due to their ability to efficiently transfer motion and power. Here are some common applications:

1. **Automotive Industry**: Used in engines to synchronize the rotation of the crankshaft and camshaft, ensuring that the engine's valves open and close at the proper times during each cylinder's intake and exhaust strokes.

2. **Manufacturing and Automation**: Employed in conveyor systems, robotic arms, and automated machinery to ensure precise movement and positioning. They help in maintaining the timing and synchronization of different machine parts.

3. **Aerospace**: Utilized in aircraft systems for controlling and synchronizing various mechanical components, ensuring reliability and precision in operations.

4. **Textile Industry**: Used in textile machinery for the precise movement of looms and other equipment, ensuring consistent fabric production.

5. **Printing Industry**: Employed in printing presses to synchronize the movement of paper and printing plates, ensuring high-quality print output.

6. **Agricultural Machinery**: Used in equipment like combines and tractors to synchronize various mechanical functions, improving efficiency and performance.

7. **Medical Equipment**: Utilized in devices such as MRI machines and other diagnostic equipment where precise movement and timing are critical.

8. **Food Processing**: Used in machinery for packaging, sorting, and processing food products, ensuring hygiene and efficiency.

9. **HVAC Systems**: Employed in heating, ventilation, and air conditioning systems to control the timing and movement of components like fans and compressors.

10. **Renewable Energy**: Used in wind turbines and solar tracking systems to ensure the precise movement and alignment of components for optimal energy capture.

These applications benefit from the timing belt pulley bar stock and flanges' ability to provide reliable, low-maintenance, and efficient power transmission.