Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Power Transmission

- Bearings

- Rolling Element Bearings

- Mounted Rolling Element Bearings

.....Read More

Frequently Asked Questions

What are the main types of mounted rolling-element bearings?

The main types of mounted rolling-element bearings are:

1. **Ball Bearings**: These bearings use balls as the rolling elements and are designed to support radial and axial loads. They are versatile and commonly used in applications requiring low friction and high-speed performance.

2. **Roller Bearings**: These bearings use cylindrical, spherical, or tapered rollers as the rolling elements. They are suitable for applications with heavy radial loads and can also accommodate some axial loads. Types include:

- **Cylindrical Roller Bearings**: Ideal for high radial loads and moderate speeds.

- **Spherical Roller Bearings**: Designed to handle heavy radial loads and misalignment.

- **Tapered Roller Bearings**: Capable of supporting both radial and axial loads, often used in automotive applications.

3. **Needle Roller Bearings**: These bearings have long, thin rollers, making them suitable for applications with limited radial space and high load capacity. They are often used in automotive and industrial machinery.

4. **Thrust Bearings**: Specifically designed to handle axial loads. They come in various forms, such as:

- **Ball Thrust Bearings**: Suitable for low-speed applications with light axial loads.

- **Roller Thrust Bearings**: Used for higher axial load capacities.

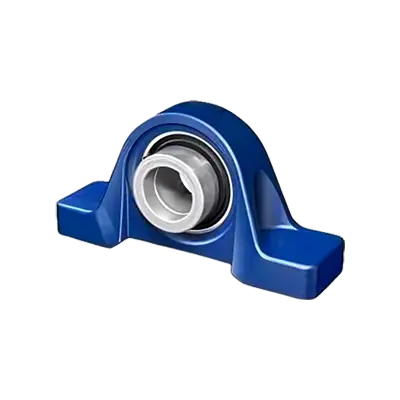

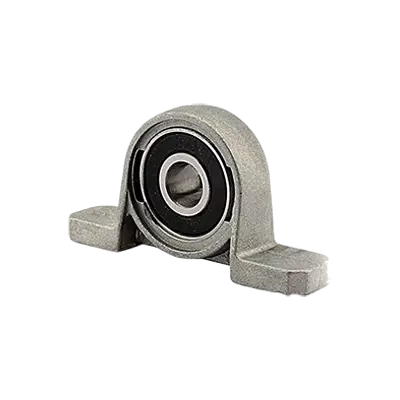

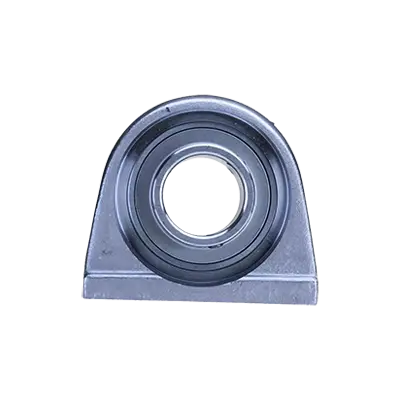

5. **Mounted Units**: These are pre-assembled bearing units that include the bearing, housing, and sealing. They simplify installation and maintenance. Types include:

- **Pillow Block Bearings**: Mounted on a pedestal or block, used for supporting rotating shafts.

- **Flange Bearings**: Mounted using a flange, suitable for applications where the shaft is perpendicular to the mounting surface.

Each type of bearing is selected based on the specific requirements of the application, including load capacity, speed, alignment, and environmental conditions.

How do flange-mount bearings differ from pillow block bearings?

Flange-mount bearings and pillow block bearings are both types of mounted bearings used to support rotating shafts, but they differ in design, mounting style, and applications.

Flange-mount bearings are designed with a flange on their outer ring, which allows them to be mounted to a surface perpendicular to the shaft. They typically come in two, three, or four-bolt configurations, providing a secure and stable mounting option. The flange design helps in aligning the bearing and shaft, making them suitable for applications where precise alignment is crucial. Flange-mount bearings are often used in applications where the shaft is parallel to the mounting surface, such as in conveyor systems, fans, and blowers.

Pillow block bearings, on the other hand, consist of a bearing housed in a pedestal or block, which is mounted on a flat surface parallel to the shaft. The housing is usually made of cast iron or steel and provides support and protection for the bearing. Pillow block bearings are designed to accommodate misalignment and are often used in applications where the shaft is horizontal and parallel to the mounting surface. They are commonly found in agricultural machinery, conveyor systems, and industrial equipment.

In summary, the primary differences between flange-mount and pillow block bearings lie in their mounting configurations and applications. Flange-mount bearings are used for perpendicular mounting and precise alignment, while pillow block bearings are used for parallel mounting and can accommodate some misalignment.

What are the applications of take-up unit bearings?

Take-up unit bearings are used in various applications where there is a need to maintain tension or alignment in conveyor systems and other machinery. These bearings are designed to accommodate misalignment and provide a means to adjust the position of the shaft to maintain proper tension. Here are some key applications:

1. **Conveyor Systems**: In material handling, take-up unit bearings are crucial for maintaining belt tension in conveyor systems. They ensure smooth operation by compensating for belt stretch and wear, preventing slippage and misalignment.

2. **Agricultural Equipment**: These bearings are used in machinery like combine harvesters and balers, where they help maintain tension in belts and chains, ensuring efficient operation and reducing downtime.

3. **Mining and Quarrying**: In harsh environments, take-up unit bearings are used in conveyors and crushers to handle heavy loads and maintain alignment, which is critical for continuous operation and reducing maintenance costs.

4. **Food and Beverage Industry**: They are employed in processing and packaging lines to maintain tension in conveyor belts, ensuring consistent product flow and reducing the risk of contamination due to misalignment.

5. **Textile Industry**: In textile machinery, take-up unit bearings help maintain tension in yarns and fabrics, ensuring uniform quality and reducing the risk of defects.

6. **Automotive Manufacturing**: These bearings are used in assembly lines to maintain tension in conveyor systems, ensuring smooth and efficient production processes.

7. **Pulp and Paper Industry**: In paper mills, take-up unit bearings help maintain tension in conveyor belts and rollers, ensuring consistent paper quality and reducing machine wear.

8. **Recycling Plants**: They are used in sorting and processing lines to maintain belt tension, ensuring efficient material handling and reducing downtime.

Overall, take-up unit bearings are essential for maintaining operational efficiency, reducing maintenance costs, and prolonging the lifespan of machinery across various industries.

How do you replace insert bearings in a mounted bearing housing?

1. **Safety First**: Ensure the machinery is turned off and locked out. Wear appropriate personal protective equipment.

2. **Remove the Housing**: Loosen and remove the bolts or screws securing the bearing housing to its mount. Carefully detach the housing from the machinery.

3. **Extract the Old Bearing**:

- Loosen the set screws or locking collar on the bearing.

- Use a bearing puller or gently tap the bearing out of the housing with a mallet, ensuring not to damage the housing.

4. **Clean the Housing**: Thoroughly clean the inside of the housing to remove any debris, dirt, or old lubricant. Inspect for any damage or wear.

5. **Prepare the New Bearing**: Check the new bearing for any defects. Apply a thin layer of lubricant to the bearing surface to ease installation.

6. **Install the New Bearing**:

- Align the bearing with the housing bore.

- Gently press or tap the bearing into place using a mallet or press, ensuring it is seated evenly and securely.

7. **Secure the Bearing**:

- Tighten the set screws or locking collar to secure the bearing in place.

- Ensure the bearing can rotate freely without obstruction.

8. **Reattach the Housing**: Position the housing back onto the machinery. Align it properly and secure it with bolts or screws.

9. **Test the Installation**:

- Rotate the shaft to ensure smooth operation.

- Run the machinery at low speed to check for any unusual noises or vibrations.

10. **Final Checks**: Re-tighten all fasteners after a short period of operation and ensure proper lubrication is maintained.

What materials are commonly used for bearing housings?

Bearing housings are typically made from materials that offer a balance of strength, durability, and resistance to environmental factors. Common materials include:

1. **Cast Iron**: Widely used due to its good machinability, wear resistance, and vibration damping properties. It is suitable for general-purpose applications.

2. **Steel**: Offers high strength and durability. Often used in applications requiring higher load capacities and where impact resistance is crucial.

3. **Ductile Iron**: Combines the strength of steel with the machinability of cast iron. It is used in applications where higher tensile strength and toughness are needed.

4. **Aluminum**: Lightweight and corrosion-resistant, making it suitable for applications where weight is a concern. It is often used in aerospace and automotive industries.

5. **Bronze**: Known for its excellent corrosion resistance and good wear properties. It is used in marine applications and environments with high moisture levels.

6. **Stainless Steel**: Offers excellent corrosion resistance and is used in food processing, chemical, and pharmaceutical industries where hygiene and resistance to corrosive substances are critical.

7. **Plastic/Polymer**: Used in applications requiring lightweight and corrosion-resistant materials. Suitable for low-load and low-speed applications.

8. **Composite Materials**: These include combinations of materials like fiberglass-reinforced plastics, offering high strength-to-weight ratios and corrosion resistance. Used in specialized applications.

Each material is chosen based on specific application requirements, including load capacity, environmental conditions, and cost considerations.

How do bearing caps protect mounted bearings?

Bearing caps protect mounted bearings by providing structural support, alignment, and containment. They secure the bearing in place, preventing it from moving or becoming misaligned during operation. This ensures that the bearing can handle the loads and stresses it encounters without shifting, which could lead to premature wear or failure.

The cap also acts as a shield against contaminants such as dust, dirt, and moisture, which can infiltrate the bearing and degrade its performance. By sealing the bearing, the cap helps maintain the lubrication within the bearing, reducing friction and wear. This prolongs the bearing's lifespan and ensures smooth operation.

Additionally, bearing caps help distribute the load evenly across the bearing, minimizing stress concentrations that could lead to damage. They are designed to fit snugly over the bearing, providing a uniform surface that supports the bearing's outer ring. This even distribution of forces helps prevent deformation or cracking of the bearing components.

In summary, bearing caps play a crucial role in maintaining the integrity and performance of mounted bearings by providing support, alignment, protection from contaminants, and load distribution.

What maintenance is required for mounted rolling-element bearings?

Maintenance for mounted rolling-element bearings involves several key practices to ensure optimal performance and longevity:

1. **Regular Inspection**: Periodically check for signs of wear, corrosion, or damage. Look for unusual noises, vibrations, or temperature changes during operation, which can indicate issues.

2. **Lubrication**: Proper lubrication is crucial. Use the correct type and amount of lubricant as specified by the manufacturer. Regularly check and replenish lubricant levels, and replace it entirely at recommended intervals to prevent contamination and ensure smooth operation.

3. **Alignment**: Ensure that the bearing is properly aligned with the shaft and housing. Misalignment can lead to uneven load distribution, increased friction, and premature failure.

4. **Load Management**: Avoid overloading the bearing beyond its rated capacity. Excessive loads can cause deformation and reduce the bearing's lifespan.

5. **Contamination Control**: Protect bearings from contaminants such as dust, dirt, and moisture. Use seals and shields as necessary, and ensure the surrounding environment is clean.

6. **Temperature Monitoring**: Keep an eye on operating temperatures. Excessive heat can degrade lubricants and materials, leading to failure. Use temperature sensors if necessary.

7. **Vibration Analysis**: Conduct regular vibration analysis to detect early signs of imbalance, misalignment, or other issues that could lead to failure.

8. **Replacement**: Replace bearings at the end of their service life or if they show signs of significant wear or damage. Always use the correct replacement parts to ensure compatibility and performance.

9. **Documentation**: Maintain detailed records of maintenance activities, inspections, and any issues encountered. This helps in tracking performance and planning future maintenance.

By adhering to these maintenance practices, the performance and lifespan of mounted rolling-element bearings can be significantly enhanced.