- Home

- Pneumatics

- Air Compressors Vacuum Pumps Blowers

- Air Compressors

- Air Compressor Accessories

.....Read More

Air Compressor Air Filter Replacement Elements

Air Compressor Covers

Air Compressor Intake Filters & Silencers

Air Compressor Oils

Air Compressor Parts Kits

Air Compressor Separator Kits

Air Compressor System Controllers

Air Compressor Valves

Engine Driven Compressor Controls

Low Oil Guards

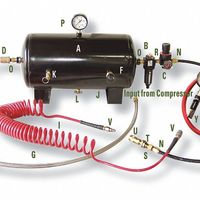

Pneumatic Tank Manifolds

Stationary Electric Air Compressor Accessories

Vehicle Mounted Air Compressor Accessories

Frequently Asked Questions

What are the essential accessories needed for air compressor maintenance?

How often should I change the oil in my air compressor?

What type of filters are best for air compressors?

How do I know when to replace air compressor valves?

What are the signs of a failing air compressor cover?

How can I extend the lifespan of my air compressor?

Where can I buy replacement parts for my air compressor?