Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Pipe Hose Tube Fittings

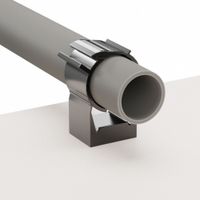

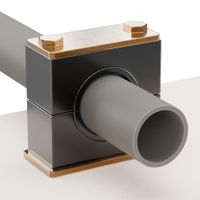

- Tube Pipe Routing Clamps Supports Hangers

- Surface Mount Tube Pipe Clamps

.....Read More

Frequently Asked Questions

What are the different types of tube and pipe clamps?

There are several types of tube and pipe clamps, each designed for specific applications and environments:

1. **Standard Pipe Clamps**: These are the most common type, used for general-purpose applications. They typically consist of a metal band with a bolt for tightening.

2. **U-Bolt Clamps**: Shaped like the letter "U," these clamps are used to secure pipes to a surface or to hang them from a support structure.

3. **Cushioned Clamps**: These have a rubber or plastic lining to reduce vibration and noise, making them ideal for applications where noise reduction is important.

4. **Hinged Clamps**: These clamps have a hinge mechanism that allows for easy installation and removal without the need to completely disassemble the clamp.

5. **Riser Clamps**: Specifically designed to support vertical pipe runs, these clamps are used in plumbing and HVAC systems.

6. **Saddle Clamps**: Used to secure pipes to a flat surface, these clamps have a saddle-like shape that cradles the pipe.

7. **Beam Clamps**: These are used to attach pipes to structural beams without the need for drilling or welding.

8. **Spring Clamps**: These clamps use a spring mechanism to apply constant pressure, useful for applications where thermal expansion and contraction occur.

9. **Hydraulic Pipe Clamps**: Designed for high-pressure hydraulic systems, these clamps are robust and often feature a heavy-duty design.

10. **Plastic Pipe Clamps**: Made from durable plastic materials, these are used in applications where metal clamps might corrode.

11. **Quick-Release Clamps**: These allow for rapid installation and removal, ideal for temporary setups or frequent maintenance.

12. **Heavy-Duty Clamps**: Built for industrial applications, these clamps can handle large pipes and high-pressure systems.

Each type of clamp is selected based on factors like pipe size, material, environmental conditions, and specific application requirements.

How do you install strut-mounted clamps?

1. **Preparation**: Gather necessary tools and materials, including the strut-mounted clamps, strut channel, screws or bolts, a drill, a wrench, and a measuring tape.

2. **Measure and Mark**: Determine the location where the strut channel will be installed. Use a measuring tape to mark the exact positions on the surface where the channel will be mounted. Ensure the alignment is straight and level.

3. **Cut the Strut Channel**: If the strut channel is not pre-cut to the required length, use a saw to cut it to size. Ensure the cut is clean and straight.

4. **Install the Strut Channel**: Position the strut channel on the marked locations. Drill holes into the surface through the pre-drilled holes in the channel. Secure the channel using appropriate screws or bolts, ensuring it is firmly attached.

5. **Position the Clamps**: Slide or position the strut-mounted clamps onto the strut channel. The clamps should align with the items they are intended to hold, such as pipes or cables.

6. **Secure the Clamps**: Tighten the clamps using a wrench or screwdriver. Ensure they are snug but not overly tight to avoid damaging the items being secured.

7. **Adjust and Align**: Check the alignment of the clamps and make any necessary adjustments to ensure they are holding the items securely and in the correct position.

8. **Final Inspection**: Inspect the entire installation to ensure all components are securely fastened and properly aligned. Make any final adjustments as needed.

9. **Clean Up**: Remove any debris or tools from the work area to complete the installation process.

What are cushioned beta clamps used for?

Cushioned beta clamps are used primarily in industrial and mechanical applications to secure and support pipes, tubes, hoses, and cables. They are designed to provide a stable and secure hold while minimizing vibration, noise, and wear. The cushioning element, typically made from rubber or other elastomeric materials, absorbs shocks and reduces the transmission of vibrations, which can be crucial in maintaining the integrity and longevity of the piping or tubing system.

These clamps are commonly used in industries such as automotive, aerospace, marine, and manufacturing, where they help in organizing and securing fluid or gas lines, electrical conduits, and other cylindrical components. The cushioned design prevents metal-to-metal contact, reducing the risk of abrasion and corrosion, which can lead to leaks or system failures.

In addition to their protective function, cushioned beta clamps facilitate easy installation and maintenance. They often come with a two-part design that allows for quick assembly and disassembly, making it easier to inspect or replace the secured components without dismantling the entire system. This feature is particularly beneficial in complex systems where downtime needs to be minimized.

Overall, cushioned beta clamps are essential for ensuring the safe and efficient operation of systems that involve the transport of fluids, gases, or electrical currents, providing both mechanical support and protection against environmental and operational stresses.

How do strap clamps differ from loop clamps?

Strap clamps and loop clamps are both used to secure objects, but they differ in design, application, and functionality.

Strap Clamps:

1. Design: Strap clamps consist of a flat, flexible strap, often made of metal or durable plastic, with a mechanism to tighten and secure the strap around an object.

2. Functionality: They are adjustable and can be tightened to apply pressure, making them suitable for holding workpieces in place during machining or assembly processes.

3. Application: Commonly used in industrial settings, strap clamps are ideal for securing large or irregularly shaped objects. They are often used in woodworking, metalworking, and automotive industries.

4. Versatility: The adjustable nature allows them to accommodate various sizes and shapes, providing a strong and secure hold.

5. Pressure: They can apply significant pressure, which is useful for tasks requiring a firm grip.

Loop Clamps:

1. Design: Loop clamps are typically U-shaped or circular, made from metal or plastic, with a single or double hole for mounting.

2. Functionality: They are designed to hold cylindrical objects, such as pipes, tubes, or cables, in place by encircling them and securing them to a surface.

3. Application: Commonly used in plumbing, electrical, and automotive applications, loop clamps are ideal for organizing and securing cables, hoses, or pipes.

4. Stability: They provide a fixed, stable hold, but are less adjustable compared to strap clamps.

5. Installation: Usually mounted with screws or bolts, loop clamps offer a permanent or semi-permanent solution for securing objects.

In summary, strap clamps are adjustable and versatile, suitable for applying pressure to various objects, while loop clamps are fixed and ideal for securing cylindrical items in place.

What is the purpose of nail clamps in plumbing?

Nail clamps in plumbing are used to secure pipes to a fixed surface, such as walls, floors, or ceilings. Their primary purpose is to hold pipes in place, preventing movement that could lead to leaks, misalignment, or damage. By securing pipes, nail clamps help maintain the integrity of the plumbing system and ensure that pipes remain in their intended positions.

These clamps are typically made of metal or plastic and are designed to fit snugly around the pipe. They come with nails or screws that are driven into the surface to anchor the clamp securely. Nail clamps are available in various sizes to accommodate different pipe diameters, ensuring a proper fit and effective support.

In addition to providing stability, nail clamps help reduce noise caused by water flow and pipe vibrations. By holding the pipes firmly, they minimize the rattling and banging sounds that can occur when water rushes through the system. This is particularly important in residential settings where noise reduction is a priority.

Furthermore, nail clamps play a role in maintaining the proper slope of drainage pipes. By securing pipes at specific intervals, they help ensure that the pipes are angled correctly to allow for efficient drainage and prevent water from pooling or backing up.

Overall, nail clamps are a crucial component in plumbing installations, contributing to the durability, functionality, and quiet operation of the system.

How do tube fastening clips work?

Tube fastening clips work by securing tubes, pipes, or cables in place, preventing movement and reducing vibration. They typically consist of a clip or clamp that encircles the tube and a mechanism to tighten and hold it securely. The clip is often made from materials like plastic, metal, or rubber, chosen based on the application and environment.

The basic operation involves placing the tube within the clip's opening. The clip is then closed around the tube, and a fastening mechanism, such as a screw, bolt, or snap-fit, is engaged to tighten the clip. This creates a firm grip on the tube, holding it in place against a surface or within a system.

Some clips have additional features like cushioning to protect the tube from abrasion or thermal expansion. Others may include quick-release mechanisms for easy removal and reinstallation. The design and material of the clip are selected based on factors like the tube's size, the environment (e.g., exposure to chemicals or temperature extremes), and the required strength of the fastening.

In summary, tube fastening clips provide a simple yet effective solution for organizing and securing tubes, ensuring stability and reducing wear and tear in various applications.

What are the benefits of using bolt-close clamps?

Bolt-close clamps offer several benefits, including:

1. **High Clamping Force**: They provide a strong and secure hold, ensuring that components remain tightly fastened during operation.

2. **Durability**: Made from robust materials, bolt-close clamps are designed to withstand high pressure and stress, making them suitable for heavy-duty applications.

3. **Versatility**: These clamps can be used in a variety of settings, from industrial machinery to automotive applications, due to their adaptable design.

4. **Precision**: They allow for precise control over the clamping force, which is crucial in applications requiring exact specifications.

5. **Safety**: By securely fastening components, bolt-close clamps help prevent accidents caused by loose parts, enhancing overall safety.

6. **Resistance to Vibration**: Their design minimizes the risk of loosening due to vibrations, making them ideal for dynamic environments.

7. **Ease of Use**: Despite their robust nature, bolt-close clamps are relatively easy to install and adjust, saving time and effort.

8. **Cost-Effectiveness**: Their durability and reliability reduce the need for frequent replacements, offering long-term cost savings.

9. **Corrosion Resistance**: Many bolt-close clamps are made from materials that resist corrosion, extending their lifespan in harsh environments.

10. **Consistency**: They provide consistent performance, which is essential for maintaining the quality and reliability of the assembly.

11. **Minimal Maintenance**: Once installed, they require little maintenance, reducing downtime and operational costs.

12. **Compatibility**: Available in various sizes and configurations, they can be tailored to fit specific requirements, enhancing their applicability across different industries.