Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

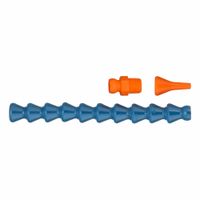

- Pipe Hose Tube Fittings

- Hose Hose Fittings Hose Reels

- Flexible Hose Systems

.....Read More

Frequently Asked Questions

What are flexible hose systems used for in machining?

Flexible hose systems in machining are primarily used for the delivery and management of fluids, such as coolants and lubricants, to the cutting area. These systems are crucial for several reasons:

1. **Cooling**: During machining, tools and workpieces can generate significant heat due to friction. Flexible hose systems deliver coolant directly to the cutting zone, reducing the temperature and preventing overheating, which can lead to tool wear or failure.

2. **Lubrication**: Proper lubrication reduces friction between the tool and the workpiece, enhancing tool life and improving surface finish. Flexible hoses ensure that lubricants are applied precisely where needed.

3. **Chip Removal**: Machining processes often produce metal chips that can obstruct the cutting area. Flexible hoses can direct high-pressure fluid streams to clear chips away, maintaining a clean work environment and preventing damage to the tool or workpiece.

4. **Versatility**: These systems can be easily adjusted to accommodate different machine setups and workpiece geometries. Their flexibility allows for quick repositioning, ensuring optimal fluid delivery regardless of the machining operation.

5. **Safety and Cleanliness**: By effectively managing fluids and chips, flexible hose systems contribute to a safer and cleaner work environment. They help contain fluids, reducing the risk of spills and slips, and minimize airborne particles that could be harmful if inhaled.

6. **Cost Efficiency**: By extending tool life and improving machining efficiency, flexible hose systems can reduce operational costs. They help maintain consistent machining conditions, leading to higher quality products and less rework.

Overall, flexible hose systems are integral to modern machining operations, enhancing performance, safety, and cost-effectiveness.

How do coolant hose systems help in cutting operations?

Coolant hose systems play a crucial role in cutting operations by delivering coolant fluids directly to the cutting zone. This process serves several important functions:

1. **Temperature Control**: Cutting operations generate significant heat due to friction between the cutting tool and the workpiece. Coolant hose systems deliver fluids that absorb and dissipate this heat, preventing overheating. This helps maintain the integrity of both the tool and the workpiece, reducing the risk of thermal damage and deformation.

2. **Lubrication**: The coolant fluid acts as a lubricant, reducing friction between the cutting tool and the material. This minimizes tool wear and extends the life of the cutting tool, leading to cost savings and improved efficiency.

3. **Chip Removal**: During cutting, chips or swarf are produced. Coolant hose systems help in flushing these chips away from the cutting area, preventing them from interfering with the cutting process. This ensures a cleaner cut and reduces the likelihood of tool breakage or damage.

4. **Surface Finish**: By maintaining optimal temperature and lubrication, coolant systems contribute to a better surface finish on the workpiece. This is particularly important in precision machining where surface quality is critical.

5. **Tool Performance**: Consistent delivery of coolant ensures that the cutting tool operates under optimal conditions, enhancing its performance and accuracy. This is vital for maintaining tight tolerances in machining operations.

6. **Safety**: By controlling heat and removing chips, coolant systems help create a safer working environment, reducing the risk of fire hazards and improving overall operational safety.

In summary, coolant hose systems are integral to efficient and effective cutting operations, enhancing tool life, workpiece quality, and operational safety.

What components are typically included in a flexible hose system?

A flexible hose system typically includes the following components:

1. **Hose**: The primary component, made from materials like rubber, PVC, or metal, designed to transport fluids or gases. It provides flexibility and strength to withstand pressure and environmental conditions.

2. **End Fittings**: Connectors attached to the ends of the hose, allowing it to be connected to other components or systems. Common types include threaded, flanged, or quick-connect fittings, made from materials like brass, stainless steel, or plastic.

3. **Couplings**: Devices used to connect two hoses or a hose to a fitting, ensuring a secure and leak-proof connection. They can be permanent or detachable, depending on the application.

4. **Clamps**: Used to secure the hose onto fittings or couplings, preventing leaks and ensuring stability. They come in various types, such as worm gear, spring, or T-bolt clamps.

5. **Protective Covers**: Shields the hose from external damage, abrasion, or environmental factors. These can be made from materials like nylon or metal mesh.

6. **Reinforcement Layers**: Embedded within the hose, these layers provide additional strength and pressure resistance. They can be made from materials like textile, wire, or synthetic fibers.

7. **Gaskets and Seals**: Ensure a tight seal between hose connections, preventing leaks. They are typically made from rubber, silicone, or other elastomers.

8. **Adapters**: Allow hoses to connect to different sizes or types of fittings, providing versatility in various applications.

9. **Support Brackets or Hangers**: Used to support the hose system, preventing sagging and reducing stress on connections.

10. **Valves**: Control the flow of fluid or gas within the system, allowing for regulation or shut-off as needed.

11. **Swivel Joints**: Allow for movement and rotation of the hose without causing stress or damage, enhancing flexibility and lifespan.

How do you configure and customize a flexible hose system?

To configure and customize a flexible hose system, follow these steps:

1. **Identify Application Requirements**: Determine the purpose, fluid type, pressure, temperature, and environmental conditions. This will guide material and design choices.

2. **Select Hose Material**: Choose materials based on compatibility with the fluid and environmental conditions. Common materials include rubber, PVC, silicone, and stainless steel.

3. **Determine Hose Size**: Calculate the required inner diameter to ensure adequate flow rate and pressure. Consider the outer diameter for fitting compatibility.

4. **Choose Hose Length**: Measure the distance between connection points, accounting for movement and flexibility needs. Avoid excessive length to minimize pressure drop.

5. **Select End Fittings**: Choose fittings compatible with the hose material and system connections. Options include threaded, flanged, quick-connect, and cam-lock fittings.

6. **Consider Reinforcement**: For high-pressure applications, select hoses with appropriate reinforcement, such as braided or spiral wire.

7. **Evaluate Bend Radius**: Ensure the hose can bend without kinking or reducing flow. Check manufacturer specifications for minimum bend radius.

8. **Assess Flexibility and Movement**: Consider the hose's ability to handle dynamic movements. Use swivel joints or flexible connectors if necessary.

9. **Incorporate Safety Features**: Add protective covers, guards, or sleeves to prevent abrasion, kinking, or external damage.

10. **Test and Validate**: Conduct pressure and leak tests to ensure system integrity. Verify that the hose meets all operational requirements.

11. **Document and Label**: Clearly label hoses with specifications and maintenance schedules. Maintain documentation for future reference and compliance.

12. **Regular Maintenance**: Implement a maintenance plan to inspect, clean, and replace hoses as needed to ensure longevity and performance.

What materials are flexible hoses made from to resist chemicals?

Flexible hoses designed to resist chemicals are typically made from materials that offer excellent chemical resistance, durability, and flexibility. Common materials include:

1. **PTFE (Polytetrafluoroethylene):** Known for its outstanding chemical resistance, PTFE hoses can handle a wide range of aggressive chemicals and high temperatures. They are non-reactive and have a low coefficient of friction.

2. **FEP (Fluorinated Ethylene Propylene):** Similar to PTFE, FEP offers excellent chemical resistance and is often used in applications requiring transparency and flexibility.

3. **PFA (Perfluoroalkoxy):** PFA hoses provide high chemical resistance and can withstand high temperatures, making them suitable for harsh chemical environments.

4. **EPDM (Ethylene Propylene Diene Monomer):** EPDM is resistant to a variety of chemicals, including acids and alkalis. It is also known for its weather and ozone resistance.

5. **Viton (Fluoroelastomer):** Viton hoses are highly resistant to chemicals, oils, and high temperatures. They are often used in applications involving aggressive chemicals and fuels.

6. **Nitrile Rubber (NBR):** Nitrile hoses offer good resistance to oils and chemicals, particularly hydrocarbons. They are commonly used in fuel and oil transfer applications.

7. **Polyurethane:** Known for its flexibility and abrasion resistance, polyurethane hoses can handle certain chemicals and are often used in applications requiring durability.

8. **Stainless Steel:** While not inherently flexible, stainless steel hoses are often used with a flexible design to provide excellent chemical resistance and mechanical strength.

9. **Composite Materials:** These hoses are made from multiple layers of different materials, providing a balance of chemical resistance, flexibility, and strength.

Each material has its specific advantages and limitations, and the choice depends on the particular chemicals involved, temperature requirements, and application conditions.

How do antistatic hoses work in reducing static buildup?

Antistatic hoses are designed to prevent the accumulation of static electricity, which can occur when materials move through the hose. These hoses work by incorporating conductive materials into their construction, which helps dissipate static charges.

The primary mechanism involves the use of conductive or semi-conductive materials, such as carbon or metal fibers, embedded within the hose walls. These materials provide a path for static electricity to flow, effectively grounding the charge and preventing buildup. The conductive elements are often integrated into the hose's inner lining or embedded throughout the hose material.

Additionally, antistatic hoses may feature a conductive helix, which is a spiral wire that runs along the length of the hose. This helix can be connected to a grounding point, further enhancing the hose's ability to dissipate static charges.

By reducing static buildup, antistatic hoses minimize the risk of static discharge, which can be hazardous in environments with flammable materials or sensitive electronic equipment. This makes them essential in industries such as chemical processing, pharmaceuticals, and electronics manufacturing, where static electricity can pose significant safety and operational challenges.

What are the benefits of using flexible hose systems in metalworking?

Flexible hose systems in metalworking offer several benefits:

1. **Versatility**: They can be easily adjusted and positioned to accommodate various machine setups and workpiece configurations, enhancing operational flexibility.

2. **Ease of Installation**: Flexible hoses are simpler to install compared to rigid piping, reducing setup time and labor costs.

3. **Vibration Absorption**: They absorb vibrations and movements from machinery, minimizing wear and tear on equipment and reducing noise levels.

4. **Space Efficiency**: Their ability to bend and curve allows them to fit into tight spaces, optimizing the use of available workspace.

5. **Reduced Maintenance**: Flexible hoses are less prone to leaks and require less maintenance than rigid systems, leading to lower downtime and repair costs.

6. **Improved Safety**: By accommodating machine movements and reducing the risk of leaks, they enhance workplace safety.

7. **Cost-Effectiveness**: Lower installation and maintenance costs, combined with increased durability, make them a cost-effective choice.

8. **Enhanced Fluid Delivery**: They provide consistent and reliable fluid delivery, crucial for cooling and lubrication in metalworking processes.

9. **Corrosion Resistance**: Many flexible hoses are made from materials that resist corrosion, extending their lifespan in harsh environments.

10. **Customization**: Available in various materials, sizes, and configurations, they can be tailored to specific applications and requirements.

11. **Quick Replacement**: In case of damage, flexible hoses can be quickly replaced without extensive downtime.

12. **Compatibility**: They are compatible with a wide range of fluids and gases used in metalworking, ensuring broad applicability.

Overall, flexible hose systems enhance efficiency, safety, and cost-effectiveness in metalworking operations.