Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Material Handling

- Structural Framing Systems

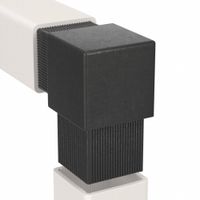

- Press Fit Framing Systems

.....Read More

Frequently Asked Questions

What are press-fit framing systems?

Press-fit framing systems are construction methods that utilize components designed to be assembled without the need for traditional fasteners like nails, screws, or adhesives. These systems rely on precision-engineered parts that fit together snugly, often using friction and tension to maintain structural integrity. The components are typically manufactured with high precision, allowing them to interlock or press into place securely.

The primary advantage of press-fit systems is their ease and speed of assembly. Since they do not require additional fastening materials, they can significantly reduce construction time and labor costs. This makes them particularly appealing for modular construction, prefabricated buildings, and temporary structures where quick assembly and disassembly are beneficial.

Press-fit systems are often used in conjunction with materials like engineered wood, metal, or composite materials, which can be manufactured to tight tolerances. The design of these systems often includes features like dovetail joints, mortise and tenon joints, or other interlocking mechanisms that enhance stability and load-bearing capacity.

In addition to speed and efficiency, press-fit framing systems offer environmental benefits. By minimizing the use of additional fasteners and adhesives, they reduce waste and the potential for chemical emissions. Furthermore, the precision manufacturing process often results in less material waste.

These systems are increasingly popular in sustainable building practices, as they align with principles of reducing resource consumption and promoting recyclability. However, they require careful design and engineering to ensure that the press-fit connections can withstand the loads and stresses they will encounter in use.

How do press-fit framing systems work?

Press-fit framing systems work by using precision-engineered components that are designed to fit together without the need for traditional fasteners like screws or nails. These systems typically consist of metal or composite materials that are manufactured to exact specifications, allowing for a snug and secure fit when assembled.

The process begins with the design phase, where components are engineered to interlock or press together. This often involves creating profiles or shapes that can slide or snap into place, providing structural integrity through friction and the precise alignment of parts. The components are usually manufactured using advanced techniques such as extrusion, casting, or machining to ensure high accuracy and consistency.

During assembly, the components are aligned and pressed together using manual force or specialized tools. The press-fit connection relies on the interference fit, where the parts are slightly larger than the openings they are meant to fit into, creating a tight bond once assembled. This method eliminates the need for additional hardware, reducing assembly time and potential points of failure.

Press-fit systems are commonly used in applications where speed, efficiency, and ease of assembly are critical. They are popular in industries such as construction, automotive, and electronics, where they provide benefits like reduced labor costs, improved aesthetics, and enhanced structural performance.

Overall, press-fit framing systems offer a streamlined approach to construction and assembly, leveraging precision engineering to create durable and reliable connections without the need for traditional fastening methods.

What are the benefits of using press-fit framing systems?

Press-fit framing systems offer several benefits:

1. **Ease of Assembly**: These systems are designed for quick and straightforward assembly, reducing the need for specialized tools or skilled labor. Components fit together seamlessly, minimizing construction time.

2. **Cost-Effective**: By reducing labor costs and construction time, press-fit systems can be more economical than traditional framing methods. The precision of prefabricated components also reduces material waste.

3. **Flexibility and Modularity**: Press-fit systems are highly adaptable, allowing for easy modifications and expansions. This modularity is ideal for projects requiring frequent updates or changes.

4. **Precision and Quality**: Manufactured under controlled conditions, press-fit components ensure high precision and consistent quality, leading to more reliable and durable structures.

5. **Sustainability**: These systems often use recyclable materials and generate less waste, contributing to more sustainable construction practices. The efficiency of the assembly process also reduces the carbon footprint.

6. **Safety**: The simplicity of the assembly process reduces the risk of on-site accidents. The need for fewer tools and heavy machinery enhances worker safety.

7. **Aesthetic Appeal**: Press-fit systems can offer sleek and modern designs, providing an aesthetically pleasing finish without compromising structural integrity.

8. **Reduced On-Site Disruption**: Faster assembly times and less noise and dust generation minimize disruption to surrounding areas, which is particularly beneficial in urban environments.

9. **Durability and Strength**: Despite their ease of assembly, press-fit systems are engineered to be robust and capable of withstanding various environmental stresses.

10. **Versatility**: Suitable for a wide range of applications, from residential to commercial and industrial projects, press-fit systems offer versatility in design and function.

Can press-fit framing systems be reconfigured easily?

Yes, press-fit framing systems can be reconfigured easily. These systems are designed for flexibility and adaptability, allowing for quick assembly and disassembly without the need for specialized tools or permanent fasteners. The components typically include modular profiles and connectors that can be easily adjusted or replaced, making it simple to modify the structure as needed. This reconfigurability is particularly advantageous in environments where space or functional requirements frequently change, such as in manufacturing, retail, or exhibition settings. The ease of reconfiguration also reduces downtime and labor costs, as changes can be implemented swiftly and efficiently.

What materials are used in press-fit framing systems?

Press-fit framing systems, commonly used in construction and manufacturing, utilize a variety of materials to ensure structural integrity, ease of assembly, and durability. The primary materials include:

1. **Aluminum**: Often used for its lightweight properties, corrosion resistance, and ease of machining. Aluminum extrusions are popular in press-fit systems due to their strength-to-weight ratio and ability to be anodized for additional surface protection.

2. **Steel**: Utilized for its strength and durability, steel components in press-fit systems are typically galvanized or coated to prevent rust and corrosion. Steel is preferred in applications requiring higher load-bearing capacity.

3. **Stainless Steel**: Chosen for its superior corrosion resistance and aesthetic appeal, stainless steel is used in environments where hygiene and cleanliness are critical, such as in food processing or medical applications.

4. **Plastics and Composites**: These materials are used for connectors, spacers, and other non-load-bearing components. They offer benefits like electrical insulation, chemical resistance, and reduced weight.

5. **Rubber and Elastomers**: Employed for gaskets, seals, and vibration dampening components, these materials provide flexibility and resilience, ensuring tight fits and reducing noise and wear.

6. **Brass and Copper**: Occasionally used for their electrical conductivity and resistance to corrosion, especially in applications involving electrical components or where antimicrobial properties are desired.

These materials are selected based on the specific requirements of the application, including environmental conditions, load requirements, and desired longevity. The combination of these materials in press-fit systems allows for versatile and efficient construction solutions.

Are press-fit framing systems strong and durable?

Press-fit framing systems are considered strong and durable due to several key factors. These systems utilize precision-engineered components that are designed to fit together tightly without the need for additional fasteners like nails or screws. This tight fit ensures a robust connection between components, which contributes to the overall strength of the structure.

The materials used in press-fit systems, often high-quality metals or engineered wood products, are selected for their strength and durability. These materials are resistant to common issues such as warping, corrosion, and degradation over time, which enhances the longevity of the structure.

The design of press-fit systems also plays a crucial role in their durability. The interlocking nature of the components distributes loads evenly across the structure, reducing stress on individual joints and minimizing the risk of failure. This load distribution is particularly beneficial in areas subject to dynamic forces, such as wind or seismic activity.

Additionally, the precision manufacturing process ensures that each component is produced to exact specifications, reducing the likelihood of defects that could compromise the system's integrity. This precision also facilitates quick and accurate assembly, which can reduce construction time and labor costs.

However, the durability of press-fit systems can be influenced by factors such as the quality of installation and environmental conditions. Proper installation by skilled professionals is essential to ensure that the system performs as intended. Moreover, while these systems are designed to withstand various environmental conditions, extreme or prolonged exposure to harsh environments may still impact their longevity.

In summary, press-fit framing systems are strong and durable due to their precision-engineered components, high-quality materials, and efficient load distribution. Proper installation and maintenance are crucial to maximizing their performance and lifespan.

How do press-fit framing systems compare to traditional framing methods?

Press-fit framing systems offer several advantages over traditional framing methods. They are designed for quick assembly, reducing construction time significantly. This is achieved through the use of pre-engineered components that fit together without the need for nails or screws, unlike traditional methods that rely heavily on manual fastening and labor-intensive processes.

The precision of press-fit systems ensures a high level of accuracy and consistency in construction, minimizing errors and material waste. This precision is often achieved through computer-aided design and manufacturing, which allows for exact specifications and reduces the likelihood of on-site adjustments.

In terms of structural integrity, press-fit systems can provide comparable or even superior strength to traditional methods. The interlocking nature of the components distributes loads more evenly, enhancing the overall stability of the structure. Additionally, these systems often use high-quality materials that are engineered for durability and performance.

From an environmental perspective, press-fit systems are generally more sustainable. They produce less waste due to their precision and efficient use of materials. Furthermore, the reduced need for on-site cutting and modification decreases the environmental impact associated with construction debris.

However, press-fit systems may have limitations in terms of design flexibility. Traditional framing allows for more customization and adaptability to unique architectural designs. Additionally, the initial cost of press-fit systems can be higher due to the need for specialized components and technology.

Overall, press-fit framing systems offer a modern, efficient alternative to traditional methods, with benefits in speed, precision, and sustainability, though they may not always be suitable for projects requiring high levels of customization.