- Home

- Material Handling

- Lifting Pulling Positioning

- Hoists Trolleys

- Replacement Components For Hoists

.....Read More

Brakes & Brake Components for Hoists

Chains, Containers, Guides, Blocks & Pins for Hoists

Handles & Grips for Lever Chain Hoists

Hooks, Hook Blocks & Hook Latches for Hoists

Labels for Hoists & Trolleys

Motors, Gears & Capacitors for Hoists

Pendant Stations & Cords for Hoists

Replacement Parts for Hoists & Trolleys

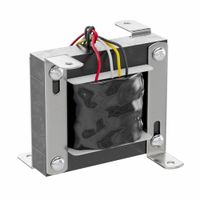

Transformers for Hoists

Frequently Asked Questions

What are the most common replacement parts needed for hoist repair?

How do I choose the right hook block for my hoist?

What is the importance of using proper lifting chains and hooks?

How can I ensure the safe operation of my hoist?

What are the signs that a hoist motor or brake needs replacement?

How do I maintain and inspect hoist components for longevity?

What should I consider when selecting a pendant station for my hoist?