Call +(254) 703 030 000 / 751 483 999 / 721 704 777

.....Read More

Frequently Asked Questions

What are mold and die milling tools used for?

Mold and die milling tools are specialized cutting tools used in the manufacturing process to shape and form materials into specific designs, typically for creating molds and dies. These tools are essential in industries such as automotive, aerospace, electronics, and consumer goods, where precision and accuracy are critical.

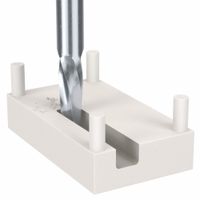

Mold milling tools are used to create molds, which are hollow cavities that shape materials like plastic, metal, or rubber into desired forms. These tools are designed to handle complex geometries and intricate details, ensuring that the final product meets exact specifications. They are often used in injection molding, blow molding, and compression molding processes.

Die milling tools, on the other hand, are used to create dies, which are specialized tools used to cut or shape material, often metal, through processes like stamping, forging, or extrusion. Dies require high precision and durability to withstand the forces involved in shaping materials.

Both mold and die milling tools are typically made from high-speed steel, carbide, or other durable materials to ensure longevity and performance. They come in various shapes and sizes, including end mills, ball nose cutters, and face mills, each designed for specific tasks such as roughing, finishing, or contouring.

The use of computer numerical control (CNC) machines has enhanced the capabilities of mold and die milling tools, allowing for greater precision, repeatability, and efficiency in the manufacturing process. This technology enables the production of complex parts with tight tolerances, reducing the need for manual intervention and increasing overall productivity.

In summary, mold and die milling tools are crucial for producing high-quality molds and dies, enabling the mass production of complex parts with precision and efficiency.

How do tapered sides benefit mold and die milling tools?

Tapered sides in mold and die milling tools offer several benefits that enhance the efficiency and quality of the machining process. Firstly, the taper provides increased tool strength and rigidity. This is crucial when cutting through hard materials, as it reduces the likelihood of tool deflection and breakage, leading to more precise and accurate cuts.

Secondly, tapered tools improve chip evacuation. The angled sides facilitate the removal of chips from the cutting area, reducing the risk of re-cutting and minimizing heat buildup. This results in a smoother surface finish and prolongs the tool's lifespan by preventing excessive wear.

Additionally, tapered tools allow for better access to complex geometries. In mold and die applications, intricate shapes and deep cavities are common. The tapered design enables the tool to reach into tight spaces and undercuts that would be challenging for straight-sided tools, enhancing the tool's versatility.

The taper also aids in reducing cutting forces. By distributing the cutting load more evenly along the tool's length, it minimizes stress concentrations, which can lead to tool failure. This distribution of forces contributes to a more stable machining process, improving the overall quality of the finished product.

Furthermore, tapered tools can enhance the surface finish of the workpiece. The gradual engagement and disengagement of the tool with the material reduce the likelihood of tool marks and chatter, resulting in a finer finish.

Lastly, the use of tapered tools can lead to cost savings. Their durability and efficiency reduce the need for frequent tool changes and rework, optimizing production time and lowering operational costs. Overall, tapered sides in milling tools are a strategic design choice that enhances performance, precision, and cost-effectiveness in mold and die manufacturing.

What is the purpose of die-sinking milling cutters?

Die-sinking milling cutters are specialized tools used primarily in the manufacturing process of creating dies, molds, and complex cavities in metalworking. Their primary purpose is to shape and form intricate and precise cavities in a workpiece, typically made of metal, by removing material through cutting. These cutters are essential in industries such as automotive, aerospace, and consumer goods, where precision and accuracy in mold and die creation are critical.

The die-sinking process involves the use of a milling machine equipped with these cutters to carve out detailed and complex shapes that are often required for producing parts with specific geometries. The cutters are designed to handle the demands of cutting through tough materials, such as hardened steel, and are available in various shapes and sizes to accommodate different design requirements.

Die-sinking milling cutters are engineered to provide high precision and surface finish, which are crucial for ensuring that the final product meets the desired specifications. They are capable of producing intricate details, such as sharp corners, deep cavities, and complex contours, which are often challenging to achieve with other machining processes.

Additionally, these cutters are designed to withstand the high stresses and temperatures generated during the milling process, ensuring durability and longevity. The use of die-sinking milling cutters enhances the efficiency and effectiveness of the die-making process, reducing production time and costs while maintaining high-quality standards.

In summary, the purpose of die-sinking milling cutters is to facilitate the creation of precise and complex cavities in metal workpieces, essential for producing high-quality dies and molds used in various industrial applications.

How are runner cutters used in mold-making?

Runner cutters are specialized tools used in mold-making to create channels, known as runners, within a mold. These channels are essential for directing molten material, such as plastic or metal, from the injection point to the various cavities of the mold. The design and implementation of runners are crucial for ensuring efficient and uniform filling of the mold cavities, which directly impacts the quality and consistency of the final product.

Runner cutters are typically used in the machining process to carve out these channels in the mold base. They come in various shapes and sizes, depending on the specific requirements of the mold design. The most common types of runner cutters include straight, tapered, and round cutters, each serving different purposes based on the flow characteristics needed for the material being used.

In practice, the use of runner cutters involves precise machining to ensure that the runners are smooth and free of obstructions, which could impede the flow of material and lead to defects in the molded parts. The dimensions and layout of the runners are carefully calculated to balance the flow rate and pressure, minimizing waste and optimizing cycle times.

Additionally, runner cutters are used to create cold runners or hot runners, depending on the mold system. Cold runners are simpler and less expensive, but they can lead to material waste. Hot runners, on the other hand, keep the material in a molten state, reducing waste but increasing the complexity and cost of the mold.

Overall, runner cutters play a vital role in mold-making by ensuring that the material is efficiently and effectively distributed throughout the mold, leading to high-quality, consistent products.

What applications require tapered end mills?

Tapered end mills are essential in various applications due to their unique geometry, which allows for precision and versatility in machining. They are primarily used in:

1. **Mold and Die Making**: Tapered end mills are crucial in the mold and die industry for creating intricate cavities and complex shapes. Their tapered design allows for the smooth creation of draft angles, which are necessary for the easy removal of molds.

2. **Aerospace Components**: In aerospace manufacturing, tapered end mills are used to machine components with complex geometries and tight tolerances. They are ideal for creating angled surfaces and intricate details in lightweight materials like aluminum and titanium.

3. **Automotive Industry**: These tools are used to produce parts with precise angles and contours, such as engine components and transmission parts, where accuracy and surface finish are critical.

4. **Prototyping**: Tapered end mills are often employed in prototyping to create detailed and accurate models. Their ability to produce fine details and smooth finishes makes them suitable for creating prototypes that closely resemble the final product.

5. **Jewelry Making**: In the jewelry industry, tapered end mills are used to craft detailed designs and patterns in precious metals. Their precision allows for the creation of intricate and delicate features.

6. **Woodworking**: Tapered end mills are used in woodworking to create detailed carvings and decorative elements. They are particularly useful for producing tapered edges and complex profiles in wood.

7. **Engraving**: These tools are used in engraving applications to produce fine details and intricate patterns on various materials, including metals, plastics, and wood.

8. **3D Contouring**: Tapered end mills are ideal for 3D contouring applications, where they can smoothly transition between different depths and angles, providing a high-quality surface finish.

Overall, tapered end mills are indispensable in industries requiring precision machining of complex shapes and angles.

How do you choose the right milling tool for mold-making?

Choosing the right milling tool for mold-making involves several key considerations:

1. **Material Compatibility**: Select tools made from materials like carbide or high-speed steel, which are suitable for the specific mold material, such as steel, aluminum, or copper alloys.

2. **Tool Geometry**: Opt for tools with appropriate geometries. For roughing, use tools with larger diameters and fewer flutes for efficient material removal. For finishing, choose tools with more flutes and smaller diameters for finer surface finishes.

3. **Coating**: Consider coated tools, such as TiN, TiAlN, or DLC, to enhance tool life and performance by reducing friction and heat generation.

4. **Tool Type**: Use end mills for general milling, ball nose end mills for 3D contouring, and corner radius end mills for improved strength and reduced chipping.

5. **Size and Length**: Select the tool size and length based on the mold cavity dimensions and depth. Longer tools may be needed for deep cavities but can introduce deflection issues.

6. **Machine Capability**: Ensure the tool is compatible with the machine's spindle speed, power, and rigidity to avoid chatter and achieve desired precision.

7. **Cutting Parameters**: Match the tool with appropriate cutting speeds, feeds, and depths of cut to optimize performance and tool life.

8. **Complexity and Precision**: For intricate designs, use high-precision tools with tighter tolerances to achieve the required detail and accuracy.

9. **Cost and Availability**: Balance the cost of the tool with its expected performance and availability, considering the project's budget and timeline.

10. **Supplier Support**: Choose tools from reputable suppliers who offer technical support and guidance for optimal tool selection and usage.

By considering these factors, you can select the most suitable milling tool for efficient and precise mold-making.

What materials are commonly used for mold and die milling tools?

Materials commonly used for mold and die milling tools include:

1. **High-Speed Steel (HSS):** Known for its toughness and resistance to high temperatures, HSS is often used for milling tools that require durability and the ability to withstand the heat generated during cutting.

2. **Carbide:** Comprising tungsten carbide particles bonded with cobalt, carbide tools are extremely hard and wear-resistant, making them ideal for high-speed applications and for cutting hard materials.

3. **Cermet:** A composite material made of ceramic and metallic materials, cermet tools offer a balance between toughness and wear resistance, suitable for finishing operations.

4. **Ceramic:** Made from alumina or silicon nitride, ceramic tools are used for high-speed machining of hard materials due to their excellent heat resistance and hardness.

5. **Cubic Boron Nitride (CBN):** Second only to diamond in hardness, CBN tools are used for machining hard ferrous materials, offering excellent wear resistance and thermal stability.

6. **Polycrystalline Diamond (PCD):** Known for its extreme hardness and wear resistance, PCD is used for non-ferrous and abrasive materials, providing a high-quality surface finish.

7. **Tool Steels:** Various grades of tool steels, such as D2 or A2, are used for their toughness and ability to maintain a sharp edge, suitable for less demanding applications.

8. **Coated Tools:** Tools are often coated with materials like titanium nitride (TiN), titanium carbonitride (TiCN), or aluminum oxide (Al2O3) to enhance their wear resistance, reduce friction, and extend tool life.

These materials are selected based on the specific requirements of the milling operation, including the type of material being machined, the desired surface finish, and the production speed.