Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Machining

- Machinery

- Metal Fabrication Machines

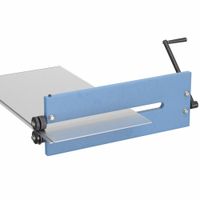

- Metal Rolling Machines

.....Read More

Frequently Asked Questions

What are the different types of metal rolling machines?

1. **Two-High Rolling Mills**: These have two opposing rolls and are used for initial breakdown of ingots. They can be non-reversing or reversing.

2. **Three-High Rolling Mills**: Consist of three rolls positioned one above the other. The workpiece passes through the bottom and middle rolls, then reverses direction to pass through the middle and top rolls.

3. **Four-High Rolling Mills**: Feature two smaller work rolls and two larger backup rolls. The backup rolls provide support to prevent deflection of the work rolls.

4. **Cluster Rolling Mills**: Utilize multiple backup rolls for each work roll, allowing for the rolling of very thin sheets.

5. **Tandem Rolling Mills**: Comprise a series of rolling stands, allowing for continuous rolling of the workpiece through multiple stages.

6. **Planetary Rolling Mills**: Have a large backup roll surrounded by a number of smaller planetary rolls, which rotate around the backup roll.

7. **Sendzimir Mills (Z-Mills)**: Use a cluster of rolls for high precision and are often used for rolling stainless steel and non-ferrous metals.

8. **Continuous Rolling Mills**: Designed for the continuous production of long products like rods and wires, using multiple stands in sequence.

9. **Ring Rolling Mills**: Used for producing seamless rings, where the ring is expanded by the pressure of the rolls.

10. **Pilger Mills**: Used for reducing the diameter and wall thickness of tubes, employing a reciprocating motion.

11. **Skew Rolling Mills**: Used for producing balls for ball bearings and grinding media, where the workpiece is rotated and deformed by skewed rolls.

12. **Universal Rolling Mills**: Capable of rolling both flat and long products, with horizontal and vertical rolls.

13. **Hydraulic Rolling Mills**: Utilize hydraulic systems for precise control of roll positioning and pressure.

How do slip and plate rolling machines work?

Slip and plate rolling machines are used to form metal sheets into cylindrical shapes or curves.

Slip rolling machines consist of three rollers: two at the bottom and one at the top. The bottom rollers are fixed, while the top roller is adjustable. The metal sheet is fed between the top and bottom rollers. As the top roller is adjusted downward, it applies pressure on the sheet, bending it into a curve. The sheet is then passed back and forth through the rollers, gradually forming a cylinder. The top roller can be removed or "slipped" out to release the finished cylinder, hence the name "slip roll."

Plate rolling machines, also known as plate bending machines, operate similarly but are designed for thicker and larger metal plates. They typically have three or four rollers. In a three-roll machine, the top roller is fixed, and the two bottom rollers are adjustable. The plate is fed between the top and bottom rollers, and the bottom rollers move upward to apply pressure, bending the plate. In a four-roll machine, the top and bottom rollers are fixed, while the side rollers are adjustable, allowing for more precise control and pre-bending of the plate edges.

Both machines rely on the principle of rolling to gradually shape the metal. The process involves multiple passes, with adjustments made to the roller positions to achieve the desired curvature. These machines are essential in industries like manufacturing, construction, and shipbuilding, where precise metal shaping is required.

What materials can be used with metal rolling machines?

Metal rolling machines are versatile tools used to shape and form various materials. The primary materials that can be used with these machines include:

1. **Steel**: This is the most common material used in metal rolling. It includes various types such as carbon steel, stainless steel, and alloy steel. Steel is favored for its strength, durability, and versatility.

2. **Aluminum**: Known for its lightweight and corrosion-resistant properties, aluminum is often used in applications where weight is a concern, such as in the automotive and aerospace industries.

3. **Copper**: With excellent electrical and thermal conductivity, copper is used in electrical applications and for making pipes and tubes.

4. **Brass**: An alloy of copper and zinc, brass is used for decorative purposes and in applications requiring low friction, such as gears and locks.

5. **Titanium**: Valued for its high strength-to-weight ratio and corrosion resistance, titanium is used in aerospace, medical devices, and high-performance applications.

6. **Nickel Alloys**: These are used in high-temperature and corrosive environments, such as in chemical processing and power generation.

7. **Magnesium**: Known for being lightweight, magnesium is used in applications where reducing weight is critical, such as in automotive and aerospace components.

8. **Zinc**: Often used for galvanizing steel to prevent rust, zinc can also be rolled into sheets for various applications.

9. **Lead**: Used in applications requiring radiation shielding and soundproofing due to its density.

10. **Precious Metals**: Gold, silver, and platinum can be rolled for use in jewelry and electronics.

These materials can be processed into sheets, bars, rods, and other shapes, depending on the specific requirements of the application. The choice of material depends on factors such as mechanical properties, corrosion resistance, weight, and cost.

What are the key features to look for in a metal rolling machine?

When selecting a metal rolling machine, consider the following key features:

1. **Material Compatibility**: Ensure the machine can handle the specific types of metal you intend to work with, such as steel, aluminum, or copper.

2. **Capacity and Size**: Check the machine's capacity in terms of thickness and width of the metal sheets it can process. This should align with your production needs.

3. **Roll Configuration**: Choose between two-roll, three-roll, or four-roll configurations based on precision and ease of use requirements. Four-roll machines offer better control and are easier to operate.

4. **Power Source**: Decide between manual, hydraulic, or electric-powered machines. Hydraulic and electric machines offer more power and efficiency for heavy-duty tasks.

5. **Control System**: Look for advanced control systems with digital displays for precision and ease of operation. CNC controls can enhance automation and repeatability.

6. **Durability and Build Quality**: Opt for machines made from high-quality materials to ensure longevity and reliability under heavy use.

7. **Safety Features**: Ensure the machine includes safety mechanisms such as emergency stop buttons, safety guards, and overload protection.

8. **Ease of Maintenance**: Consider machines with accessible components for easy maintenance and servicing.

9. **Speed and Efficiency**: Evaluate the machine's rolling speed and efficiency to match your production timelines.

10. **Versatility**: Some machines offer additional features like bending or cutting, which can be beneficial for diverse applications.

11. **Brand Reputation and Support**: Choose reputable brands known for quality and customer support, including availability of spare parts and technical assistance.

12. **Cost and ROI**: Balance the initial investment with the machine's capabilities and potential return on investment.

These features will help ensure you select a metal rolling machine that meets your operational needs and enhances productivity.

How do you maintain and care for a metal rolling machine?

To maintain and care for a metal rolling machine, follow these steps:

1. **Regular Cleaning**: Clean the machine daily to remove metal shavings, dust, and debris. Use a soft brush or cloth to prevent scratches.

2. **Lubrication**: Apply appropriate lubricants to moving parts regularly to reduce friction and wear. Check the manufacturer's guidelines for recommended lubricants and intervals.

3. **Inspection**: Conduct routine inspections for signs of wear, damage, or misalignment. Pay special attention to rollers, bearings, and gears.

4. **Alignment**: Ensure rollers are properly aligned to prevent uneven rolling and material damage. Adjust as necessary.

5. **Tightening**: Check and tighten all bolts, nuts, and screws periodically to maintain structural integrity and prevent vibrations.

6. **Calibration**: Regularly calibrate the machine to ensure precision in operations. Follow the manufacturer's instructions for calibration procedures.

7. **Cooling System**: If equipped, maintain the cooling system by checking fluid levels and ensuring there are no leaks or blockages.

8. **Electrical Components**: Inspect electrical connections and components for signs of wear or damage. Replace any faulty wiring or components immediately.

9. **Safety Features**: Test safety features such as emergency stops and guards to ensure they are functioning correctly.

10. **Training**: Ensure operators are well-trained in machine operation and maintenance procedures to prevent misuse and accidents.

11. **Documentation**: Keep detailed records of maintenance activities, inspections, and repairs to track the machine's condition and schedule future maintenance.

12. **Professional Servicing**: Schedule regular professional servicing to address complex issues and ensure the machine operates at peak efficiency.

By adhering to these maintenance practices, you can extend the lifespan of your metal rolling machine and ensure its optimal performance.

What safety precautions should be taken when using metal rolling machines?

1. **Training and Certification**: Ensure operators are properly trained and certified to use the machine.

2. **Personal Protective Equipment (PPE)**: Wear appropriate PPE, including gloves, safety glasses, steel-toed boots, and hearing protection.

3. **Machine Guarding**: Ensure all guards and safety devices are in place and functioning properly to prevent accidental contact with moving parts.

4. **Emergency Stop Mechanisms**: Familiarize yourself with the location and operation of emergency stop buttons and ensure they are easily accessible.

5. **Regular Maintenance**: Conduct routine maintenance checks to ensure the machine is in good working condition and free from defects.

6. **Clear Work Area**: Keep the area around the machine clean and free of obstructions to prevent tripping and ensure easy access to controls.

7. **Proper Material Handling**: Use appropriate tools and techniques for loading and unloading materials to avoid manual handling injuries.

8. **Safe Operating Procedures**: Follow the manufacturer’s guidelines and standard operating procedures for safe machine operation.

9. **Two-Person Rule**: Implement a two-person rule for certain operations to ensure assistance is available in case of an emergency.

10. **Avoid Loose Clothing and Jewelry**: Do not wear loose clothing, jewelry, or anything that could get caught in the machine.

11. **Pre-Operation Inspection**: Conduct a pre-operation inspection to check for any visible damage or issues with the machine.

12. **Lockout/Tagout Procedures**: Use lockout/tagout procedures during maintenance or when the machine is not in use to prevent accidental start-up.

13. **Awareness and Focus**: Stay alert and focused while operating the machine, avoiding distractions.

14. **Communication**: Maintain clear communication with other workers in the area to coordinate operations and ensure safety.

15. **Emergency Preparedness**: Be prepared for emergencies by knowing the location of first aid kits and emergency exits.

How do you choose the right metal rolling machine for your needs?

To choose the right metal rolling machine, consider the following factors:

1. **Material Type and Thickness**: Determine the type of metal (steel, aluminum, etc.) and its thickness. Different machines are designed to handle specific materials and thickness ranges.

2. **Capacity and Size**: Assess the machine's capacity in terms of width and diameter of the rolls. Ensure it can accommodate the size of the metal sheets or plates you intend to roll.

3. **Type of Rolling Machine**: Decide between initial-pinch, pyramid, or double-pinch machines based on your specific rolling needs. Each type offers different advantages in terms of precision and ease of use.

4. **Production Volume**: Consider the volume of production. For high-volume production, a more robust and automated machine may be necessary, while smaller operations might suffice with a manual or semi-automatic machine.

5. **Precision and Tolerance**: Evaluate the precision and tolerance levels required for your projects. Some machines offer higher precision, which is crucial for applications demanding tight tolerances.

6. **Automation and Control Features**: Look for machines with advanced control systems for ease of operation and increased efficiency. CNC-controlled machines offer high precision and repeatability.

7. **Budget**: Determine your budget, balancing between cost and the features you need. Consider both the initial investment and long-term operational costs.

8. **Space and Installation**: Ensure you have adequate space for the machine and consider the installation requirements, including power supply and foundation needs.

9. **Manufacturer and Support**: Choose a reputable manufacturer known for quality and reliability. Consider the availability of customer support, training, and maintenance services.

10. **Future Needs**: Anticipate future production needs and choose a machine that can adapt to potential changes in your operations.

By evaluating these factors, you can select a metal rolling machine that aligns with your operational requirements and business goals.