Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

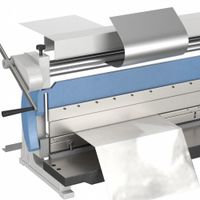

- Machining

- Machinery

- Metal Fabrication Machines

- Ironworkers Combination Machines

.....Read More

Frequently Asked Questions

What is an ironworker machine used for?

An ironworker machine is a versatile tool used in metalworking to perform various tasks such as shearing, punching, notching, bending, and forming metal materials. These machines are essential in fabrication shops, manufacturing plants, and construction sites due to their ability to handle heavy-duty operations efficiently and accurately.

Ironworker machines are designed to work with a range of materials, including steel, aluminum, and other metals, making them ideal for producing components for structures, machinery, and other industrial applications. They are equipped with multiple stations, each dedicated to a specific function, allowing operators to switch between tasks without needing separate machines. This multi-functionality enhances productivity and reduces the need for additional equipment.

The shearing station is used to cut metal sheets and plates to size, while the punching station creates holes of various shapes and sizes in metal workpieces. The notching station is employed to cut out sections or corners of metal sheets, facilitating the creation of complex shapes and designs. Bending and forming stations allow for the shaping of metal into desired angles and curves, essential for creating brackets, frames, and other structural components.

Ironworker machines are available in different sizes and capacities, catering to small workshops and large industrial operations. They can be manually operated, hydraulic, or powered by electric motors, with hydraulic models being the most common due to their power and precision.

Overall, ironworker machines are indispensable in the metalworking industry, providing a cost-effective and efficient solution for processing metal materials, reducing labor costs, and improving production speed and quality.

How does a hydraulic ironworker machine work?

A hydraulic ironworker machine operates using hydraulic power to perform various metalworking tasks such as shearing, punching, notching, and bending. The machine consists of a robust frame housing multiple workstations, each designed for specific operations.

The core component is the hydraulic system, which includes a hydraulic pump, reservoir, valves, and cylinders. The pump draws hydraulic fluid from the reservoir and pressurizes it, sending it through valves to the cylinders. These cylinders convert hydraulic energy into mechanical force, driving the machine's tools.

For shearing, the machine uses a set of blades to cut metal sheets or bars. The operator positions the material under the blade, and the hydraulic cylinder lowers the upper blade to shear the metal against a fixed lower blade.

In punching, the machine uses a punch and die set. The operator places the metal under the punch, and the hydraulic cylinder forces the punch through the material, creating holes of various shapes and sizes.

Notching involves removing sections from the edge of metal sheets. The operator aligns the material with the notching tool, and the hydraulic system drives the tool to cut out the desired section.

Bending is achieved by pressing the metal between a punch and a die, forming it into the desired angle or shape. The hydraulic force ensures precise and consistent bends.

The machine's versatility and efficiency make it essential in metal fabrication, allowing for quick tool changes and adjustments to accommodate different materials and thicknesses. Safety features, such as guards and emergency stops, ensure operator protection during operation.

What are the different types of ironworker machines?

Ironworker machines are versatile tools used in metalworking to shear, notch, and punch holes in steel plates and profiles. The different types include:

1. **Hydraulic Ironworkers**: These use hydraulic systems to deliver powerful force, making them suitable for heavy-duty tasks. They are known for their precision and efficiency.

2. **Mechanical Ironworkers**: Operate using mechanical systems, typically with a flywheel. They are generally faster than hydraulic models but may not handle as heavy loads.

3. **Single-Operator Ironworkers**: Designed for one person to operate, these machines are compact and suitable for smaller workshops or less intensive tasks.

4. **Dual-Operator Ironworkers**: Allow two operators to work simultaneously on different tasks, increasing productivity. They are ideal for larger operations.

5. **Manual Ironworkers**: Operated by hand, these are suitable for light-duty tasks and are often used in small workshops or for educational purposes.

6. **CNC Ironworkers**: Equipped with computer numerical control, these machines offer high precision and automation, suitable for complex and repetitive tasks.

7. **Portable Ironworkers**: Lightweight and mobile, these machines can be easily transported to different job sites, ideal for on-site work.

8. **Stationary Ironworkers**: Fixed in one location, these are typically more robust and powerful, suitable for heavy-duty industrial applications.

Each type of ironworker machine is designed to meet specific needs, from small-scale operations to large industrial applications, offering various capabilities in terms of force, speed, and precision.

What maintenance is required for an ironworker machine?

Regular maintenance of an ironworker machine is crucial to ensure its optimal performance and longevity. Key maintenance tasks include:

1. **Lubrication**: Regularly lubricate all moving parts, including gears, bearings, and pivot points, to reduce friction and prevent wear. Use the manufacturer-recommended lubricants.

2. **Inspection**: Conduct routine inspections for any signs of wear, damage, or misalignment in components such as blades, punches, and dies. Replace or repair any worn or damaged parts immediately.

3. **Blade and Die Maintenance**: Sharpen or replace blades and dies as needed to ensure clean cuts and punches. Dull tools can lead to poor-quality work and increased machine strain.

4. **Hydraulic System**: Check hydraulic fluid levels regularly and top up as necessary. Inspect hoses and connections for leaks or damage. Replace hydraulic filters according to the manufacturer's schedule.

5. **Electrical System**: Inspect electrical connections and wiring for signs of wear or damage. Ensure that all safety switches and emergency stops are functioning correctly.

6. **Alignment and Calibration**: Regularly check and adjust the alignment and calibration of the machine to ensure precision in operations. Misalignment can lead to inaccurate cuts and increased wear.

7. **Cleaning**: Keep the machine clean from metal shavings, dust, and debris. Regular cleaning prevents buildup that can interfere with machine operation.

8. **Safety Checks**: Regularly test safety features and guards to ensure they are operational. This includes checking emergency stop buttons and safety interlocks.

9. **Documentation**: Maintain a detailed log of all maintenance activities, inspections, and repairs. This helps in tracking the machine's condition and planning future maintenance.

10. **Training**: Ensure operators are trained in proper machine use and maintenance procedures to prevent misuse and extend the machine's life.

Adhering to these maintenance practices will help in minimizing downtime and extending the service life of an ironworker machine.

How do you choose the right ironworker machine for your needs?

To choose the right ironworker machine, first assess your specific needs by considering the types of materials you will work with, such as steel, aluminum, or other metals, and the thickness of these materials. Determine the primary operations you require, such as punching, shearing, notching, or bending, and prioritize these based on your workflow.

Next, evaluate the machine's capacity, ensuring it can handle the maximum thickness and size of materials you plan to process. Consider the tonnage required for your operations, as this will affect the machine's ability to perform tasks efficiently.

Consider the machine's versatility and the range of attachments or tooling options available, which can expand its functionality. Look for features like adjustable stroke length, quick-change tooling systems, and multi-station capabilities to enhance productivity and flexibility.

Assess the machine's build quality and durability, focusing on the frame construction and components to ensure it can withstand heavy use. Check for reputable brands known for reliability and good customer support.

Evaluate the machine's ease of use, including the control system and safety features, to ensure it aligns with your operators' skill levels and safety standards. Consider the machine's footprint and power requirements to ensure it fits within your workspace and infrastructure.

Finally, consider your budget, balancing the initial cost with long-term value, including maintenance, repair costs, and potential downtime. Compare different models and manufacturers, read reviews, and, if possible, see demonstrations or consult with industry experts to make an informed decision.

What are the benefits of using a combination machine?

A combination machine offers several benefits, particularly in woodworking and metalworking environments:

1. **Space Efficiency**: Combination machines integrate multiple functions into a single unit, saving valuable floor space in workshops, which is especially beneficial for small or home-based operations.

2. **Cost-Effectiveness**: Purchasing a combination machine is often more economical than buying separate machines for each function. This can be a significant advantage for hobbyists or small businesses with limited budgets.

3. **Versatility**: These machines typically combine functions such as sawing, planing, jointing, and drilling, allowing users to perform a variety of tasks without needing multiple machines. This versatility can enhance productivity and workflow efficiency.

4. **Convenience**: With all functions in one machine, users can switch between tasks more easily and quickly, reducing downtime and increasing overall efficiency.

5. **Reduced Maintenance**: Maintaining one machine instead of several can simplify upkeep and reduce maintenance costs. It also minimizes the need for spare parts and service calls.

6. **Ease of Use**: Combination machines are often designed with user-friendly controls and interfaces, making them accessible to both beginners and experienced operators.

7. **Consistent Quality**: By using a single machine for multiple tasks, users can achieve consistent quality and precision across different operations, as the machine settings and alignments remain constant.

8. **Enhanced Safety**: With fewer machines in the workshop, there are fewer opportunities for accidents. Additionally, combination machines often come with integrated safety features to protect users during operation.

9. **Flexibility**: These machines can be adapted to various project requirements, making them suitable for a wide range of applications and materials.

Overall, combination machines offer a practical solution for maximizing efficiency, reducing costs, and maintaining high-quality output in various manufacturing and crafting environments.

How do you safely operate an ironworker machine?

To safely operate an ironworker machine, follow these steps:

1. **Training and Familiarization**: Ensure you are properly trained and familiar with the specific model of the ironworker machine you will be using. Understand its functions, controls, and safety features.

2. **Personal Protective Equipment (PPE)**: Wear appropriate PPE, including safety glasses, gloves, steel-toed boots, and hearing protection to protect against noise and flying debris.

3. **Pre-Operation Inspection**: Conduct a thorough inspection of the machine before use. Check for any signs of wear, damage, or malfunction. Ensure all guards and safety devices are in place and functioning.

4. **Work Area Preparation**: Keep the work area clean and free of obstructions. Ensure adequate lighting and ventilation. Mark off the operational area to keep unauthorized personnel away.

5. **Material Handling**: Use proper lifting techniques or mechanical aids to handle heavy materials. Ensure materials are securely positioned and clamped before operation.

6. **Machine Setup**: Adjust the machine settings according to the material specifications and the task at hand. Double-check the alignment and positioning of the material.

7. **Operation**: Operate the machine using the designated controls. Keep hands and body parts away from moving parts. Use push sticks or other tools to guide materials when necessary.

8. **Emergency Procedures**: Be aware of the machine’s emergency stop functions and know how to quickly shut down the machine if needed.

9. **Post-Operation**: After use, turn off the machine and disconnect the power supply. Clean the machine and work area, and report any issues to maintenance personnel.

10. **Regular Maintenance**: Follow the manufacturer’s maintenance schedule to ensure the machine remains in safe working condition.

By adhering to these guidelines, you can minimize the risk of accidents and ensure safe operation of an ironworker machine.