Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Machining

- Clamping Workholding Positioning

- Stationary Fixturing

.....Read More

Frequently Asked Questions

What are stationary fixturing tools used for?

Stationary fixturing tools are used to securely hold, support, and position workpieces during manufacturing processes to ensure precision, stability, and repeatability. These tools are essential in various industries, including automotive, aerospace, electronics, and metalworking, where high accuracy and consistency are critical.

The primary purpose of stationary fixturing tools is to maintain the workpiece in a fixed position relative to the machine tool or processing equipment. This stability is crucial for operations such as machining, welding, assembly, inspection, and testing. By preventing movement or vibration, fixturing tools help achieve precise cuts, welds, or measurements, thereby enhancing the quality and accuracy of the final product.

Stationary fixturing tools also facilitate increased production efficiency. By allowing quick and easy loading and unloading of workpieces, they reduce setup times and enable faster transitions between different production stages. This efficiency is particularly beneficial in high-volume manufacturing environments where time savings can lead to significant cost reductions.

Moreover, these tools contribute to worker safety by minimizing the need for manual handling of workpieces during operations. By securely holding the workpiece, they reduce the risk of accidents and injuries associated with manual adjustments or movements.

Fixturing tools come in various forms, including clamps, jigs, vices, and custom-designed fixtures tailored to specific applications. They can be made from materials like steel, aluminum, or composites, depending on the requirements of the task and the properties of the workpiece.

In summary, stationary fixturing tools are vital components in manufacturing processes, ensuring precision, efficiency, and safety by securely holding workpieces in place during various operations.

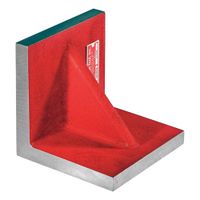

How do angle plates ensure precision in machining?

Angle plates ensure precision in machining by providing a stable and accurate reference surface for workpieces. They are typically made from cast iron or steel, which offers rigidity and resistance to deformation. The precision-ground surfaces of angle plates maintain perpendicularity, ensuring that the workpiece is held at a precise angle, usually 90 degrees, relative to the machine table or another reference surface.

The use of angle plates allows for the accurate alignment of workpieces during machining operations such as drilling, milling, or grinding. By securely clamping the workpiece to the angle plate, machinists can prevent movement or vibration, which could lead to errors or inconsistencies in the final product. This stability is crucial for maintaining tight tolerances and achieving the desired surface finish.

Angle plates also facilitate the machining of complex geometries by allowing workpieces to be oriented in various positions. This versatility enables machinists to perform multiple operations without repositioning the workpiece, reducing setup time and minimizing the risk of misalignment.

Furthermore, angle plates often feature slots or holes for clamping, which enhance their adaptability to different workholding requirements. This flexibility ensures that angle plates can accommodate a wide range of workpiece sizes and shapes, further contributing to precision in machining.

In summary, angle plates ensure precision in machining by providing a stable, accurate, and versatile reference surface that maintains the correct orientation of workpieces, minimizes movement, and supports complex machining operations.

What is the purpose of box parallels in machining applications?

Box parallels in machining applications serve several critical purposes:

1. **Workpiece Support and Stability**: Box parallels provide a stable and elevated platform for workpieces during machining. They ensure that the workpiece is securely positioned above the machine table, allowing for better access and machining operations.

2. **Height Adjustment**: They help in adjusting the height of the workpiece to align it with the cutting tool. This is crucial for operations that require precise depth control, such as drilling, milling, or boring.

3. **Clearance and Access**: By elevating the workpiece, box parallels create necessary clearance for cutting tools and machine components. This is particularly important for operations that involve through-holes or require access to the underside of the workpiece.

4. **Parallelism and Flatness**: Box parallels are manufactured to high standards of parallelism and flatness. They ensure that the workpiece is parallel to the machine table, which is essential for maintaining dimensional accuracy and consistency in machining operations.

5. **Versatility**: They can be used in various setups and configurations, accommodating different sizes and shapes of workpieces. This versatility makes them a valuable tool in both standard and custom machining applications.

6. **Reduction of Vibration**: By providing a solid and stable base, box parallels help in reducing vibrations during machining. This leads to improved surface finish and accuracy of the machined parts.

7. **Facilitation of Clamping**: Box parallels often have slots or holes that facilitate easy clamping of the workpiece. This ensures that the workpiece remains securely in place during machining, preventing movement that could lead to errors.

Overall, box parallels are essential for achieving precision, stability, and efficiency in machining processes.

How do collet indexers enhance four-axis machining?

Collet indexers enhance four-axis machining by providing precise and efficient workpiece positioning and rotation capabilities. They allow for the secure clamping of workpieces, which is crucial for maintaining accuracy and repeatability during machining operations. By using collets, which are known for their high gripping force and concentricity, collet indexers ensure that the workpiece is held firmly in place, reducing the risk of slippage or misalignment.

In four-axis machining, the addition of a rotary axis (typically the A-axis) allows for the machining of complex geometries and features on multiple sides of a workpiece without the need for repositioning. Collet indexers facilitate this by enabling quick and accurate indexing of the workpiece to the desired angle or position. This capability is particularly beneficial for operations such as drilling, milling, and tapping on cylindrical or irregularly shaped parts.

Furthermore, collet indexers contribute to increased productivity by minimizing setup times and reducing the need for multiple fixtures. Their ability to quickly change collets to accommodate different workpiece sizes and shapes enhances the flexibility of the machining process. This adaptability is essential in environments where a variety of parts are produced in small to medium batches.

Overall, collet indexers improve the efficiency, precision, and versatility of four-axis machining, making them a valuable tool in modern manufacturing processes.

What are fixture plates and how do they work?

Fixture plates, also known as tooling plates, are flat, precision-ground plates used in manufacturing and machining to hold workpieces securely in place during operations. They are typically made from materials like aluminum, steel, or cast iron, chosen for their durability and resistance to wear.

Fixture plates work by providing a stable and repeatable platform for mounting workpieces. They have a grid of threaded holes or slots that allow for the attachment of clamps, vises, or other workholding devices. This grid system enables precise positioning and alignment of the workpiece, ensuring consistent machining results.

The primary function of fixture plates is to reduce setup time and increase efficiency in production. By using a fixture plate, operators can quickly swap out workpieces without the need to recalibrate the machine for each new part. This repeatability is crucial in high-volume manufacturing environments where time and precision are critical.

Fixture plates also enhance flexibility in machining operations. They can accommodate a wide variety of workpiece shapes and sizes, making them suitable for different projects without the need for custom fixtures. This adaptability reduces costs and streamlines the production process.

In summary, fixture plates are essential tools in machining that provide a stable, repeatable, and flexible platform for securing workpieces. They improve efficiency, precision, and adaptability in manufacturing operations.

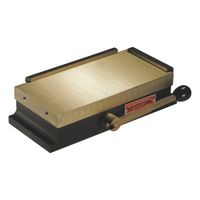

How do magnetic chucks hold workpieces without clamps?

Magnetic chucks hold workpieces without the need for mechanical clamps by utilizing magnetic force to secure the material in place. These devices are commonly used in machining operations such as grinding, milling, and turning. The core principle behind their operation is the use of a magnetic field to create an attractive force between the chuck and the ferromagnetic workpiece.

The magnetic chuck consists of a series of magnets, which can be either permanent magnets or electromagnets. Permanent magnetic chucks use strong, permanent magnets to generate a consistent magnetic field. The workpiece is placed on the chuck, and the magnetic field penetrates the material, creating a strong bond that holds it securely in place. This setup is advantageous for its simplicity and energy efficiency, as it does not require an external power source.

Electromagnetic chucks, on the other hand, use an electric current to generate a magnetic field. When the current flows through the coil within the chuck, it creates a magnetic field that attracts the workpiece. The strength of the magnetic field can be adjusted by varying the current, allowing for precise control over the holding force. This type of chuck requires a continuous power supply to maintain the magnetic field, but it offers the advantage of easy demagnetization, allowing for quick release of the workpiece.

Both types of magnetic chucks provide a uniform holding force across the entire surface of the workpiece, minimizing distortion and ensuring stability during machining. This method eliminates the need for mechanical clamps, reducing setup time and allowing for unobstructed access to the workpiece, which is particularly beneficial for complex machining operations.

What is the function of rotary machining tables in precision tasks?

Rotary machining tables, also known as rotary tables, play a crucial role in precision tasks by enabling the accurate and efficient machining of complex parts. These tables allow for the precise rotation of a workpiece around a fixed axis, which is essential for tasks that require intricate detailing and multi-axis machining.

The primary function of rotary machining tables is to provide a stable and precise platform for the workpiece, allowing it to be rotated at specific angles. This capability is vital for operations such as milling, drilling, and cutting, where the workpiece needs to be accessed from multiple angles without repositioning it manually. By facilitating continuous rotation, rotary tables enhance the accuracy and repeatability of machining processes, which is critical in industries like aerospace, automotive, and medical device manufacturing.

Rotary tables are often integrated with CNC (Computer Numerical Control) systems, which further enhances their precision by allowing for automated control of the rotation angle and speed. This integration enables complex geometries to be machined with high precision, reducing the likelihood of human error and increasing production efficiency.

Additionally, rotary tables can be used for indexing, which involves dividing a workpiece into equal segments for machining. This is particularly useful in tasks that require symmetrical features, such as gear cutting or the creation of circular patterns.

In summary, rotary machining tables are indispensable in precision tasks due to their ability to provide accurate rotational control, enhance machining flexibility, and improve the overall quality of the finished product. Their integration with CNC systems further amplifies their utility, making them a vital component in modern manufacturing processes.