Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Machining

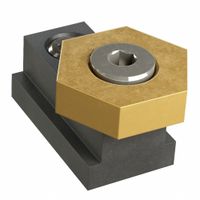

- Clamping Workholding Positioning

- Machine Table Clamps

.....Read More

Frequently Asked Questions

What are machine table clamps used for?

Machine table clamps are essential tools used in machining and manufacturing processes to securely hold workpieces in place on a machine table. These clamps ensure stability and precision during operations such as milling, drilling, grinding, and other machining tasks. By firmly securing the workpiece, machine table clamps prevent movement and vibration, which can lead to inaccuracies, defects, or damage to both the workpiece and the machine.

There are various types of machine table clamps, each designed for specific applications and workpiece geometries. Common types include T-slot clamps, step clamps, toggle clamps, and strap clamps. T-slot clamps fit into the T-slots of a machine table, providing a versatile and adjustable clamping solution. Step clamps are used for holding workpieces of varying heights, while toggle clamps offer quick-release mechanisms for fast setup and removal. Strap clamps provide a strong, even pressure across the workpiece surface.

The use of machine table clamps enhances safety by minimizing the risk of workpiece ejection during high-speed operations. They also contribute to efficiency by reducing setup time and allowing for repeatable, consistent positioning of workpieces. In automated and CNC machining environments, precise clamping is crucial for maintaining the accuracy of programmed tool paths and ensuring high-quality output.

Overall, machine table clamps are indispensable in achieving the precision, safety, and efficiency required in modern manufacturing processes.

How do you choose the right machine clamping kit?

To choose the right machine clamping kit, consider the following factors:

1. **Machine Type and Size**: Ensure the clamping kit is compatible with your machine's specifications, including table size and T-slot dimensions.

2. **Material and Durability**: Select kits made from high-quality materials like hardened steel for durability and resistance to wear and tear.

3. **Clamping Force**: Determine the required clamping force based on the machining operation. Heavier operations need stronger clamping.

4. **Versatility**: Opt for kits with a variety of clamping elements such as step blocks, T-nuts, and studs to accommodate different workpieces and setups.

5. **Ease of Use**: Choose kits that are easy to assemble and adjust, reducing setup time and increasing efficiency.

6. **Precision and Stability**: Ensure the kit provides stable and precise clamping to maintain workpiece accuracy during machining.

7. **Cost**: Balance cost with quality and features. Investing in a reliable kit can save money in the long run by reducing downtime and maintenance.

8. **Brand Reputation**: Consider kits from reputable manufacturers known for quality and customer support.

9. **Reviews and Recommendations**: Check user reviews and seek recommendations from industry peers to gauge performance and reliability.

10. **Safety Features**: Ensure the kit includes safety features to prevent accidents and ensure operator safety.

By evaluating these factors, you can select a machine clamping kit that meets your operational needs and enhances machining efficiency.

What are the different types of machine clamps?

Machine clamps are essential tools used to hold workpieces securely in place during machining operations. Here are the different types:

1. **Toggle Clamps**: These are quick-action clamps that use a pivot and lever system to hold workpieces. They are available in various configurations, such as horizontal, vertical, and push-pull.

2. **C-Clamps**: These versatile clamps have a C-shaped frame and a screw mechanism to apply pressure. They are commonly used for temporary holding.

3. **Bar Clamps**: Featuring a long bar with adjustable jaws, these clamps are ideal for holding large workpieces. They provide even pressure distribution.

4. **Pipe Clamps**: Utilizing a pipe as the backbone, these clamps are adjustable and suitable for clamping wide or irregularly shaped objects.

5. **Bench Clamps**: Mounted on workbenches, these clamps provide a stable and adjustable clamping solution for various tasks.

6. **Step Clamps**: Used in milling and machining, these clamps have a stepped design to accommodate different workpiece heights.

7. **Cam Clamps**: These clamps use a cam mechanism to apply pressure quickly and are often used in woodworking and light-duty applications.

8. **Edge Clamps**: Designed to hold the edges of workpieces, these clamps are useful for tasks like gluing or edge banding.

9. **Strap Clamps**: These use a strap or band to apply pressure, making them suitable for irregularly shaped objects.

10. **Magnetic Clamps**: Utilizing magnetic force, these clamps are ideal for holding ferrous materials without marring the surface.

11. **Vacuum Clamps**: These use suction to hold workpieces, often used in CNC machining for delicate or thin materials.

12. **Hydraulic Clamps**: Providing high clamping force, these are used in heavy-duty applications and can be automated for efficiency.

Each type of clamp serves specific purposes and is chosen based on the requirements of the machining operation.

How do step blocks work in clamping setups?

Step blocks are essential components in clamping setups, primarily used in machining and manufacturing processes to secure workpieces. They function by providing adjustable support and height to accommodate various workpiece sizes and shapes. Typically made from hardened steel for durability, step blocks have a series of steps or notches of varying heights on one side, allowing for precise height adjustments.

In a clamping setup, step blocks are paired with clamps and bolts to hold a workpiece firmly on a machine table, such as a milling machine or drill press. The process begins by selecting the appropriate step block height that matches the workpiece's thickness. The step block is then placed under the clamp, with the chosen step resting on the machine table. The clamp is positioned over the workpiece, and a bolt is inserted through the clamp and into the machine table's T-slot or threaded hole.

As the bolt is tightened, the clamp presses down on the workpiece, while the step block provides a stable base, preventing the clamp from tilting or slipping. The stepped design allows for quick adjustments, enabling operators to change the clamping height without needing additional tools or components. This versatility makes step blocks ideal for setups requiring frequent changes or adjustments.

Moreover, step blocks help distribute clamping forces evenly, reducing the risk of workpiece deformation or damage. They also enhance safety by ensuring the workpiece remains securely in place during machining operations. Overall, step blocks are crucial for achieving precision, stability, and efficiency in clamping setups.

What is the purpose of toggle pads in clamping?

Toggle pads in clamping systems serve the purpose of enhancing the efficiency and effectiveness of the clamping process. They are integral components in toggle clamps, which are mechanical devices used to hold workpieces securely in place during various operations such as machining, welding, or assembly. The primary purposes of toggle pads include:

1. **Force Distribution**: Toggle pads help in distributing the clamping force evenly across the surface of the workpiece. This prevents damage or deformation, especially in delicate or soft materials, ensuring that the workpiece remains intact and undamaged during the process.

2. **Stability and Security**: By providing a stable contact surface, toggle pads enhance the security of the clamping action. This stability is crucial for maintaining the precision and accuracy of the operation being performed, as any movement or slippage can lead to errors or defects.

3. **Vibration Damping**: Toggle pads can also serve to dampen vibrations that occur during machining or other operations. This damping effect helps in maintaining the integrity of the workpiece and the quality of the finished product by reducing the risk of chatter marks or other surface imperfections.

4. **Versatility**: Toggle pads can be designed to accommodate various shapes and sizes of workpieces, making them versatile for different applications. They can be easily adjusted or replaced to suit specific requirements, enhancing the adaptability of the clamping system.

5. **Ease of Use**: The design of toggle pads often allows for quick and easy setup and release, improving the efficiency of the workflow. This ease of use is particularly beneficial in high-volume production environments where time savings are critical.

Overall, toggle pads are essential for optimizing the performance of clamping systems, ensuring that workpieces are held securely, accurately, and without damage during industrial processes.

How do T-slot clamps function?

T-slot clamps function by utilizing a T-slot track, which is a common feature on machine tables, workbenches, and other fixtures. These clamps are designed to hold workpieces securely in place during machining, assembly, or other operations. Here's how they work:

1. **T-slot Track**: The T-slot is a specially shaped groove, resembling an inverted "T," that runs along the surface of a table or fixture. This track allows for the insertion and movement of T-slot nuts and bolts.

2. **T-slot Nut**: The T-slot nut is a key component that slides into the T-slot track. It has a threaded hole that allows for the attachment of various clamping devices. The nut's shape prevents it from rotating within the slot, providing a stable base for the clamp.

3. **Clamping Mechanism**: The clamp itself typically consists of a clamping arm and a bolt or screw. The bolt passes through the clamping arm and threads into the T-slot nut. By tightening the bolt, the clamping arm is pressed down onto the workpiece, securing it against the table or fixture.

4. **Adjustability**: T-slot clamps are highly adjustable. The T-slot nut can slide along the track to position the clamp precisely where needed. The clamping arm can also pivot or adjust in height, accommodating various workpiece sizes and shapes.

5. **Versatility**: These clamps are versatile and can be used in a variety of applications, from woodworking to metalworking. They are ideal for holding irregularly shaped objects or for setups that require frequent adjustments.

6. **Secure Hold**: The design ensures a strong, secure hold, minimizing movement or vibration during operations, which is crucial for precision work.

Overall, T-slot clamps provide a flexible, reliable, and efficient method for securing workpieces in a wide range of industrial and workshop settings.

What are the benefits of using machine table clamps?

Machine table clamps offer several benefits that enhance the efficiency and precision of machining operations:

1. **Stability and Security**: Clamps provide a secure hold on the workpiece, preventing movement during machining. This stability is crucial for maintaining accuracy and ensuring that the workpiece does not shift, which could lead to errors or damage.

2. **Precision**: By firmly holding the workpiece in place, clamps allow for precise machining operations. This precision is essential for producing parts with tight tolerances and intricate details.

3. **Versatility**: Machine table clamps come in various designs and sizes, making them suitable for a wide range of applications and workpiece shapes. This versatility allows for quick adjustments and adaptability to different machining tasks.

4. **Efficiency**: Clamps enable quick setup and changeover times, reducing downtime between operations. This efficiency is particularly beneficial in high-volume production environments where time savings can lead to increased productivity.

5. **Safety**: Properly secured workpieces reduce the risk of accidents caused by workpiece movement or ejection during machining. This safety aspect is critical in maintaining a safe working environment for operators.

6. **Cost-Effectiveness**: By minimizing errors and rework, clamps contribute to cost savings. They also extend the life of cutting tools by reducing vibrations and ensuring consistent contact with the workpiece.

7. **Improved Surface Finish**: Stable clamping reduces vibrations and chatter, leading to a better surface finish on the machined part. This improvement is important for both aesthetic and functional reasons.

8. **Customization**: Many clamps can be customized or adjusted to fit specific workpieces or machining requirements, offering tailored solutions for unique challenges.

Overall, machine table clamps are essential tools that enhance the quality, efficiency, and safety of machining processes.