Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Machining

- Clamping Workholding Positioning

- Indexing Positioning Equipment

.....Read More

Frequently Asked Questions

What are the main types of indexing and positioning equipment used in machining?

The main types of indexing and positioning equipment used in machining include:

1. **Rotary Tables**: These are used to position workpieces at precise angles for machining operations. They can be manually operated or CNC-controlled, allowing for accurate rotation and positioning.

2. **Indexing Heads (Dividing Heads)**: These devices allow for the precise division of a workpiece into equal parts. They are essential for operations like gear cutting, where exact spacing is crucial.

3. **CNC Indexers**: These are computer-controlled devices that provide high precision and flexibility in positioning workpieces. They are often used in conjunction with CNC machines for complex operations.

4. **Fixture Plates**: These are flat plates with a grid of holes or slots that allow for the secure mounting and positioning of workpieces. They provide a stable base for machining operations.

5. **Jigs and Fixtures**: Custom-designed tools that hold, support, and locate a workpiece during machining. They ensure repeatability, accuracy, and interchangeability in manufacturing processes.

6. **Tailstocks**: Used in conjunction with rotary tables or lathes, tailstocks provide support for long workpieces, ensuring stability and precision during machining.

7. **Linear Positioning Systems**: These systems use linear guides and actuators to move workpieces or tools along a straight path with high precision. They are essential for operations requiring exact linear movement.

8. **Pallet Systems**: These systems allow for quick and accurate positioning of workpieces on machine tools. They enable fast changeovers and increased productivity in manufacturing environments.

9. **Angle Plates**: Used to hold workpieces at a specific angle relative to the machine table. They are essential for machining operations that require angled cuts or drilling.

10. **Vices and Clamps**: These are used to hold workpieces securely in place during machining. They come in various designs to accommodate different shapes and sizes of workpieces.

How do plungers work in positioning equipment setups?

Plungers, often referred to as spring plungers or indexing plungers, are mechanical components used in positioning equipment setups to ensure precise alignment, secure holding, and accurate positioning of parts. They consist of a body, a spring, and a plunger tip. The body is typically threaded, allowing it to be easily installed into a fixture or equipment. The spring provides the necessary force to push the plunger tip outward.

In operation, the plunger is inserted into a hole or slot on the equipment or workpiece. The spring force keeps the plunger tip engaged with the surface, maintaining the position of the component. This engagement ensures that the part remains in the desired location, even when subjected to external forces or vibrations. The plunger can be retracted by applying a force against the spring, allowing for repositioning or removal of the component.

Plungers are crucial in applications requiring repeatable positioning, such as in jigs, fixtures, and assembly lines. They provide a simple yet effective means of achieving consistent alignment and positioning without the need for complex mechanisms. The use of plungers can significantly reduce setup time and improve the accuracy and efficiency of manufacturing processes.

Different types of plungers are available, including those with various tip shapes (e.g., flat, rounded, or pointed) and materials (e.g., steel, stainless steel, or plastic), to suit specific applications. Some plungers also feature locking mechanisms to prevent accidental retraction, enhancing safety and reliability in critical applications. Overall, plungers are essential components in positioning equipment setups, offering a reliable and cost-effective solution for maintaining precise alignment and positioning.

What is the purpose of locating pins in machining fixtures?

Locating pins in machining fixtures serve the critical purpose of ensuring precise and repeatable positioning of a workpiece during machining operations. These pins are integral to the fixture design, providing a reference point that aligns the workpiece in a consistent orientation relative to the cutting tools and machine axes. This alignment is crucial for maintaining dimensional accuracy and ensuring that each part produced meets the specified tolerances.

The primary functions of locating pins include:

1. **Positioning**: Locating pins accurately position the workpiece in the fixture, ensuring that it is correctly aligned for machining. This prevents misalignment that could lead to defects or variations in the finished product.

2. **Repeatability**: By providing a consistent reference point, locating pins enable the fixture to repeatedly position multiple workpieces in the same orientation. This repeatability is essential for high-volume production where uniformity and consistency are critical.

3. **Stability**: Locating pins help stabilize the workpiece within the fixture, reducing movement or vibration during machining. This stability is vital for achieving precise cuts and maintaining the integrity of the machining process.

4. **Orientation**: Locating pins ensure that the workpiece is oriented correctly, which is particularly important for parts with complex geometries or features that must be machined in a specific sequence.

5. **Efficiency**: By simplifying the setup process, locating pins reduce the time and effort required to position each workpiece, thereby increasing overall production efficiency.

In summary, locating pins are essential components in machining fixtures, providing the necessary precision, repeatability, and stability to produce high-quality parts efficiently.

How do positioning feet ensure repeatability in machining processes?

Positioning feet play a crucial role in ensuring repeatability in machining processes by providing a stable and consistent reference point for the workpiece or the machine itself. These feet are designed to maintain the alignment and level of the machine, which is essential for precision machining. By ensuring that the machine is consistently positioned, positioning feet help in minimizing variations that can occur due to machine movement or vibration.

Firstly, positioning feet help in maintaining the machine's level. A machine that is not level can lead to uneven cutting, which affects the repeatability of the machining process. By keeping the machine level, positioning feet ensure that each machining operation starts from the same baseline, reducing errors and improving consistency.

Secondly, positioning feet absorb vibrations and shocks that can occur during machining. Vibrations can lead to tool deflection and workpiece movement, both of which can cause deviations in the machining process. By dampening these vibrations, positioning feet help maintain the tool's path and the workpiece's position, ensuring that each cut is consistent with the previous one.

Additionally, positioning feet facilitate quick and accurate setup of the machine. When a machine is moved or reconfigured, positioning feet allow it to be returned to its original position with high precision. This repeatability in setup is crucial for batch production, where multiple parts need to be machined to the same specifications.

In summary, positioning feet ensure repeatability in machining processes by maintaining machine level, absorbing vibrations, and enabling precise machine setup. This leads to consistent machining operations, reduced errors, and improved quality of the final product.

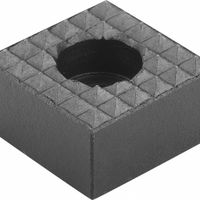

What are the benefits of using positioning grippers with serrated surfaces?

Positioning grippers with serrated surfaces offer several benefits in industrial and manufacturing applications:

1. **Enhanced Grip Stability**: The serrated surface increases the contact area between the gripper and the object, providing a more secure hold. This reduces the risk of slippage, especially when handling smooth or slippery materials.

2. **Improved Precision**: The increased friction from the serrated surface allows for more precise positioning of objects. This is crucial in applications requiring exact placement, such as assembly lines or robotic operations.

3. **Versatility**: Serrated grippers can handle a variety of materials and shapes, from flat to irregular surfaces. This adaptability makes them suitable for diverse applications without the need for frequent tool changes.

4. **Reduced Damage**: While providing a firm grip, the serrated design can distribute pressure more evenly across the object's surface, minimizing the risk of damage or deformation, especially on delicate items.

5. **Increased Load Capacity**: The enhanced grip allows the gripper to handle heavier loads without compromising stability, improving efficiency in material handling tasks.

6. **Durability**: Serrated surfaces are often more resistant to wear and tear, extending the lifespan of the gripper. This durability is beneficial in high-frequency operations, reducing maintenance costs and downtime.

7. **Cost-Effectiveness**: By reducing slippage and damage, serrated grippers can lower operational costs associated with product loss and equipment maintenance.

8. **Safety**: A more secure grip reduces the likelihood of dropped objects, enhancing workplace safety and reducing the risk of injury or equipment damage.

Overall, positioning grippers with serrated surfaces provide a reliable, versatile, and efficient solution for handling a wide range of materials in various industrial settings.

How can indexing equipment improve the accuracy of machining operations?

Indexing equipment enhances the accuracy of machining operations by providing precise control over the positioning and movement of workpieces or tools. This precision is crucial for achieving tight tolerances and consistent quality in manufactured parts.

1. **Consistent Positioning**: Indexing devices, such as rotary tables and indexing heads, allow for the exact positioning of a workpiece at specific angles or intervals. This ensures that each machining operation is performed at the correct location, reducing errors and improving repeatability.

2. **Reduced Human Error**: By automating the positioning process, indexing equipment minimizes the potential for human error. Manual adjustments can lead to inaccuracies, but automated indexing ensures that each step is executed with precision.

3. **Enhanced Multi-Axis Machining**: In complex machining operations involving multiple axes, indexing equipment facilitates the accurate alignment of the workpiece or tool. This is essential for operations like drilling, milling, or cutting at various angles, ensuring that each cut is made precisely as intended.

4. **Improved Efficiency**: Indexing equipment can quickly and accurately reposition workpieces, reducing downtime between operations. This efficiency not only speeds up the production process but also maintains high levels of accuracy throughout.

5. **Repeatability**: The ability to return to exact positions repeatedly is a key advantage of indexing equipment. This repeatability is vital for batch production, where each part must meet the same specifications.

6. **Complex Geometries**: For parts with complex geometries, indexing equipment allows for precise machining from multiple angles and orientations, ensuring that intricate designs are executed accurately.

Overall, indexing equipment is a critical component in modern machining operations, providing the precision and control necessary to produce high-quality parts consistently.

What factors should be considered when selecting positioning equipment for a specific application?

When selecting positioning equipment for a specific application, consider the following factors:

1. **Load Capacity**: Ensure the equipment can handle the weight and size of the load, including any dynamic forces during operation.

2. **Precision and Accuracy**: Determine the required level of precision and accuracy for the application, as this will influence the choice of equipment with appropriate resolution and repeatability.

3. **Speed and Acceleration**: Evaluate the necessary speed and acceleration to meet the application's cycle time requirements without compromising performance.

4. **Environment**: Consider environmental conditions such as temperature, humidity, dust, and potential exposure to chemicals or moisture, which may affect equipment performance and durability.

5. **Space Constraints**: Assess the available space for installation and operation, ensuring the equipment fits within the physical constraints of the application area.

6. **Control System Compatibility**: Ensure compatibility with existing control systems and software, including communication protocols and integration capabilities.

7. **Power Requirements**: Check the power supply specifications and ensure the equipment can operate efficiently within the available power infrastructure.

8. **Maintenance and Reliability**: Consider the maintenance needs and reliability of the equipment, including ease of access for servicing and the availability of spare parts.

9. **Cost**: Evaluate the total cost of ownership, including initial purchase price, installation, maintenance, and potential downtime costs.

10. **Safety**: Ensure the equipment meets safety standards and includes necessary safety features to protect operators and the surrounding environment.

11. **Flexibility and Scalability**: Consider the potential for future modifications or expansions, ensuring the equipment can adapt to changing needs.

12. **Supplier Support**: Assess the level of technical support and service provided by the supplier, including training, troubleshooting, and after-sales service.