- Home

- Lab Supplies

- Lab Storage Transport

.....Read More

Frequently Asked Questions

What are the best practices for storing lab equipment and samples?

How do you safely transport vaccines and lab samples?

What types of containers are recommended for heating and storing lab samples?

How do lab sampling bags ensure sterility and safety?

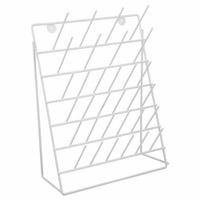

What are the benefits of using lab storage racks for organizing equipment?

How do specimen transfer bags ensure safe handling and disposal?

What features should I look for in lab mailers for sample protection during shipping?

How do lab carts and accessories improve workflow in a laboratory?

What are the advantages of using stainless steel containers in a lab setting?

How do specimen transport coolers maintain the temperature of samples during transit?