Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

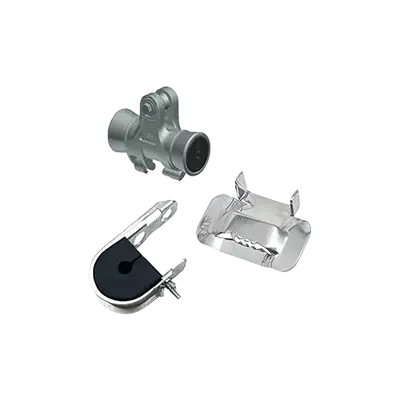

- Information Communication Network

- Osp Hardware

.....Read More

Frequently Asked Questions

What is OSP Hardware?

OSP (Outside Plant) Hardware refers to the physical infrastructure and components used in telecommunications and networking that are located outside of buildings. This includes the equipment and materials necessary for the installation, operation, and maintenance of communication networks. Key components of OSP hardware include:

1. **Cables**: These are the backbone of OSP, including fiber optic cables, copper cables, and coaxial cables, which transmit data over long distances.

2. **Conduits and Ducts**: Protective pathways for cables, often buried underground or installed on poles, to safeguard against environmental damage.

3. **Poles and Towers**: Structures that support aerial cables and antennas, providing elevation for signal transmission.

4. **Enclosures and Cabinets**: Weatherproof housings that protect sensitive equipment like switches, routers, and power supplies from environmental elements.

5. **Splice Closures**: Devices used to join and protect fiber optic or copper cable splices, ensuring signal integrity and protection from moisture and contaminants.

6. **Cross-Connects and Patch Panels**: Hardware that facilitates the connection and management of cables, allowing for network configuration and troubleshooting.

7. **Grounding and Bonding Equipment**: Essential for safety and equipment protection, these components prevent electrical surges and static discharge.

8. **Power Supply Systems**: Includes backup batteries and generators to ensure continuous operation during power outages.

9. **Network Interface Devices (NIDs)**: Serve as the demarcation point between the service provider's network and the customer's premises.

10. **Antennas and Transceivers**: Used in wireless communication to transmit and receive signals.

OSP hardware is crucial for the reliable delivery of telecommunications services, including internet, telephone, and television, and requires regular maintenance to ensure optimal performance and longevity.

What are the key components of OSP Hardware?

The key components of Outside Plant (OSP) hardware include:

1. **Cables**: These are the primary medium for data transmission and include fiber optic cables, copper cables, and coaxial cables. They are designed to withstand environmental conditions.

2. **Conduits and Ducts**: These protective pathways house and protect cables from physical damage and environmental factors. They facilitate easy installation and maintenance.

3. **Poles and Towers**: Used to support aerial cables and other equipment, these structures are crucial for maintaining the physical infrastructure of OSP.

4. **Enclosures and Cabinets**: These provide secure housing for equipment such as splice closures, distribution frames, and network interface devices, protecting them from environmental elements.

5. **Splice Closures**: These are used to protect and organize fiber optic splices, ensuring the integrity and performance of the network.

6. **Cross-Connects and Patch Panels**: These components facilitate the connection and management of cables, allowing for flexible network configurations and easy troubleshooting.

7. **Terminals and Pedestals**: These are access points for connecting customer premises to the network, often housing connection points and splitters.

8. **Grounding and Bonding Equipment**: Essential for safety and performance, these components protect the network from electrical surges and ensure proper operation.

9. **Manholes and Handholes**: Underground access points that allow technicians to access and manage cables and other infrastructure components.

10. **Network Interface Devices (NIDs)**: These devices serve as the demarcation point between the service provider's network and the customer's premises, facilitating service delivery and troubleshooting.

11. **Splitters and Amplifiers**: Used in fiber and coaxial networks, these components distribute and boost signals to ensure optimal performance across the network.

12. **Markers and Labels**: These are used for identification and maintenance purposes, ensuring that all components are easily identifiable and accessible.

How does OSP Hardware support telecommunications networks?

OSP (Outside Plant) hardware supports telecommunications networks by providing the physical infrastructure necessary for the transmission of data over long distances. This includes a variety of components and systems that are installed outside of buildings to facilitate connectivity and communication.

1. **Cabling**: OSP hardware includes fiber optic and copper cables that are laid underground, on poles, or through conduits. These cables form the backbone of telecommunications networks, enabling high-speed data transmission.

2. **Conduits and Ducts**: These are protective pathways for cables, safeguarding them from environmental damage and physical wear. They also allow for easier maintenance and upgrades.

3. **Poles and Towers**: Used to support aerial cables and antennas, these structures are essential for maintaining line-of-sight communication and expanding network reach.

4. **Enclosures and Cabinets**: These protect sensitive equipment like switches, routers, and power supplies from environmental factors such as moisture, dust, and temperature extremes.

5. **Splice Closures**: These are used to join and protect fiber optic cables, ensuring signal integrity and minimizing loss during transmission.

6. **Cross-Connects and Patch Panels**: These components facilitate the routing and rerouting of connections, allowing for network flexibility and scalability.

7. **Power Supply Systems**: OSP hardware includes backup power solutions like batteries and generators to ensure network reliability during power outages.

8. **Monitoring and Control Systems**: These systems provide real-time data on network performance and environmental conditions, enabling proactive maintenance and rapid response to issues.

By integrating these components, OSP hardware ensures robust, reliable, and efficient telecommunications networks, supporting everything from voice calls to high-speed internet and data services.

What types of cables are used in OSP Hardware?

In Outside Plant (OSP) hardware, several types of cables are commonly used to ensure reliable communication and data transmission. These include:

1. **Fiber Optic Cables**: These are the backbone of modern telecommunications, offering high bandwidth and long-distance transmission capabilities. They are used for both aerial and underground installations and come in single-mode and multi-mode types.

2. **Copper Cables**: Traditional copper cables, such as twisted pair cables, are still used in OSP for shorter distances. They include Category 5e, Category 6, and Category 6a cables, primarily for DSL and telephone services.

3. **Coaxial Cables**: Used for cable television and internet services, coaxial cables are known for their shielding, which reduces electromagnetic interference. They are suitable for both aerial and underground installations.

4. **Hybrid Cables**: These combine fiber optic and copper cables in a single sheath, allowing for both power and data transmission. They are often used in Fiber to the Antenna (FTTA) applications.

5. **Ribbon Cables**: These are a type of fiber optic cable where multiple fibers are arranged in a flat, ribbon-like structure. They are used for high-density applications and are easy to splice.

6. **Armored Cables**: Designed for harsh environments, these cables have an additional protective layer to prevent damage from rodents, moisture, and physical impact. They are used in both fiber optic and copper cable types.

7. **Aerial Cables**: Specifically designed for overhead installations, these cables are reinforced to withstand environmental factors like wind and ice.

8. **Buried Cables**: These are designed for direct burial underground and are equipped with protective layers to resist moisture and physical damage.

Each type of cable is selected based on the specific requirements of the OSP environment, including distance, bandwidth, and environmental conditions.

How are fiber optic cables installed in OSP infrastructure?

Fiber optic cables in OSP (Outside Plant) infrastructure are installed through a series of steps:

1. **Planning and Design**: Engineers conduct site surveys to determine the best route, considering factors like terrain, existing infrastructure, and environmental impact. Detailed plans and permits are obtained.

2. **Trenching and Duct Installation**: Trenches are dug along the planned route. Conduits or ducts are laid in these trenches to protect the fiber cables. In urban areas, micro-trenching or directional boring may be used to minimize disruption.

3. **Cable Pulling or Blowing**: Fiber optic cables are either pulled through the ducts using a winch or blown using compressed air. Blowing is preferred for longer distances as it reduces stress on the cables.

4. **Splicing and Termination**: Cables are spliced at various points to connect different sections. Fusion splicing is commonly used for its low loss and high reliability. Termination involves connecting the fiber to network equipment using connectors.

5. **Testing and Documentation**: After installation, cables are tested for signal loss, continuity, and performance using OTDR (Optical Time-Domain Reflectometer) and other testing equipment. Results are documented for future reference.

6. **Backfilling and Restoration**: Trenches are backfilled, and the surface is restored to its original condition. This includes repaving roads or replanting vegetation.

7. **Maintenance and Monitoring**: Regular inspections and maintenance are conducted to ensure the integrity of the fiber network. Monitoring systems may be installed to detect faults or performance issues.

This process ensures a reliable and efficient fiber optic network in OSP infrastructure.

What is the role of enclosures in OSP Hardware?

Enclosures in Outside Plant (OSP) hardware play a critical role in protecting and organizing telecommunications and networking equipment deployed in outdoor environments. These enclosures are designed to safeguard sensitive electronic components from environmental factors such as moisture, dust, temperature fluctuations, and physical damage. By providing a controlled environment, enclosures ensure the reliability and longevity of the equipment housed within.

One of the primary functions of OSP enclosures is to offer weatherproofing. They are typically constructed from durable materials like stainless steel, aluminum, or high-grade plastics, which are resistant to corrosion and can withstand harsh weather conditions. This protection is crucial for maintaining uninterrupted service and preventing equipment failure due to exposure to the elements.

Enclosures also provide security against unauthorized access and vandalism. They are often equipped with locking mechanisms and are designed to be tamper-resistant, ensuring that only authorized personnel can access the equipment. This security feature is vital for protecting sensitive data and maintaining network integrity.

Additionally, enclosures facilitate cable management and organization. They are designed with specific compartments and entry points for cables, allowing for neat and efficient routing. This organization helps in reducing signal interference and makes maintenance and troubleshooting more manageable.

Thermal management is another critical aspect of OSP enclosures. They often include features such as ventilation systems, fans, or heat exchangers to regulate the internal temperature, preventing overheating of the equipment. This thermal control is essential for maintaining optimal performance and preventing damage due to excessive heat.

In summary, enclosures in OSP hardware are essential for environmental protection, security, cable management, and thermal regulation, ensuring the efficient and reliable operation of telecommunications infrastructure in outdoor settings.

How do splitters and amplifiers function in OSP systems?

In Outside Plant (OSP) systems, splitters and amplifiers play crucial roles in managing and distributing optical signals.

**Splitters:**

Optical splitters are passive devices used to divide a single optical signal into multiple signals. They are essential in Passive Optical Networks (PONs) for distributing signals from a central office to multiple endpoints. Splitters work by taking an incoming optical signal and splitting it into several outputs, each carrying a fraction of the original signal's power. The most common types are 1xN or 2xN splitters, where 'N' represents the number of outputs. Splitters are designed to maintain signal integrity while minimizing loss, although some signal attenuation is inevitable due to the division of power among the outputs.

**Amplifiers:**

Optical amplifiers are active devices used to boost the strength of optical signals without converting them to electrical signals. They are crucial in long-distance fiber optic communication to counteract signal attenuation over extended distances. The most common type is the Erbium-Doped Fiber Amplifier (EDFA), which amplifies signals in the C-band and L-band wavelengths. Amplifiers work by using a doped fiber and a pump laser to increase the power of the optical signal passing through. They help maintain signal quality and extend the reach of the network by compensating for losses incurred from fiber attenuation, splitting, and other network components.

Together, splitters and amplifiers ensure efficient signal distribution and strength in OSP systems, enabling reliable and high-capacity communication networks.

What are the environmental considerations for OSP Hardware?

Environmental considerations for Outside Plant (OSP) hardware include:

1. **Weather Resistance**: OSP hardware must withstand various weather conditions such as rain, snow, extreme temperatures, and UV radiation. Materials used should be corrosion-resistant and durable.

2. **Temperature Fluctuations**: Equipment should be able to operate efficiently across a wide temperature range without performance degradation.

3. **Moisture and Humidity**: Sealing and waterproofing are crucial to prevent moisture ingress, which can lead to corrosion and electrical failures.

4. **Wind and Vibration**: Hardware should be designed to endure high winds and vibrations, especially in areas prone to storms or seismic activity.

5. **Pollution and Contaminants**: Consideration for resistance to pollutants, dust, and other airborne contaminants that can affect performance and longevity.

6. **Wildlife and Vegetation**: Protection against damage from animals and plant overgrowth is necessary, including the use of barriers or repellents.

7. **Sustainability**: Use of eco-friendly materials and processes, including recyclability and reduced carbon footprint during manufacturing and installation.

8. **Energy Efficiency**: Minimizing energy consumption of active components to reduce environmental impact and operational costs.

9. **Electromagnetic Interference (EMI)**: Ensuring that hardware does not emit or is not susceptible to EMI, which can affect both the environment and other electronic devices.

10. **Regulatory Compliance**: Adherence to environmental regulations and standards, such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment).

11. **End-of-Life Disposal**: Planning for responsible disposal or recycling of hardware at the end of its lifecycle to minimize environmental impact.

How is OSP Hardware maintained and serviced?

OSP (Outside Plant) hardware is maintained and serviced through a series of structured processes to ensure reliability and performance. Regular inspections are conducted to identify wear and tear, corrosion, or damage caused by environmental factors. Preventive maintenance involves cleaning, tightening connections, and replacing worn components to prevent failures.

Technicians perform routine testing of cables, connectors, and other components to ensure signal integrity and performance. This includes using specialized equipment to measure signal strength, attenuation, and other parameters. Fault detection and diagnostics are crucial, often employing tools like time-domain reflectometers (TDR) to locate faults in cables.

Repairs are carried out promptly when issues are identified. This may involve splicing cables, replacing damaged sections, or repairing connectors. For fiber optics, precise splicing and testing are essential to maintain signal quality.

Documentation is a critical aspect of OSP maintenance. Detailed records of inspections, tests, repairs, and upgrades are maintained to track the history and condition of the infrastructure. This helps in planning future maintenance and upgrades.

Environmental factors such as weather conditions, vegetation growth, and human activities are monitored, and protective measures like weatherproof enclosures, cable shielding, and proper grounding are implemented to mitigate risks.

Training and certification of personnel ensure that maintenance is performed to industry standards. Safety protocols are strictly followed to protect both the technicians and the infrastructure.

Finally, technology upgrades are periodically assessed and implemented to enhance performance and capacity, ensuring the OSP hardware meets current and future demands. This may involve replacing outdated equipment with more advanced technology, such as transitioning from copper to fiber optic cables.

What are the latest advancements in OSP Hardware technology?

The latest advancements in Outside Plant (OSP) hardware technology focus on enhancing the efficiency, reliability, and scalability of telecommunications infrastructure. Key developments include:

1. **Fiber Optic Innovations**: The deployment of bend-insensitive fibers and higher-capacity cables, such as those supporting 200-micron fibers, allows for more compact and efficient installations. These advancements facilitate higher data rates and longer transmission distances without signal degradation.

2. **5G Infrastructure**: The rollout of 5G networks has driven the need for advanced OSP hardware, including small cell technology and distributed antenna systems (DAS). These systems enhance coverage and capacity, particularly in urban environments.

3. **Smart Poles and Cabinets**: Integration of IoT technology into OSP hardware, such as smart poles and cabinets, enables real-time monitoring and management of network components. This leads to improved maintenance and reduced downtime.

4. **Advanced Splicing and Connectivity Solutions**: New splicing machines and connectors offer faster, more reliable fiber connections. Innovations like mechanical splice connectors and fusion splicers with automated features improve installation efficiency.

5. **Environmental Resilience**: OSP hardware is increasingly designed to withstand harsh environmental conditions. This includes the use of corrosion-resistant materials and enclosures that protect against extreme weather, ensuring network reliability.

6. **Power Solutions**: The development of more efficient power supply systems, including renewable energy options like solar-powered OSP equipment, supports sustainable network operations and reduces dependency on traditional power sources.

7. **Modular and Scalable Designs**: Modular OSP hardware allows for easy upgrades and expansions, accommodating future network growth and technological advancements without significant infrastructure overhauls.

These advancements collectively enhance the performance and sustainability of telecommunications networks, supporting the growing demand for high-speed, reliable connectivity.