Call +(254) 703 030 000 / 751 483 999 / 721 704 777

.....Read More

Frequently Asked Questions

What are the best materials for O-rings in sealing applications?

The best materials for O-rings in sealing applications depend heavily on the specific operating conditions, including temperature, pressure, chemical compatibility, and mechanical stress. Some of the most common and effective materials include:

Nitrile (Buna-N): This is a widely used and cost-effective elastomer, offering good resistance to oils, fuels, water, and some solvents. It's suitable for a broad temperature range but has limited resistance to ozone, sunlight, and some strong acids.

Viton (FKM): Known for its excellent chemical resistance, especially to aggressive fuels, oils, and chemicals, and a wide operating temperature range. Viton is often chosen for high-performance and critical sealing applications.

Silicone: Offers superior flexibility and a very broad temperature range, making it ideal for extreme hot or cold environments. However, silicone has poor resistance to abrasion, oils, and fuels, limiting its use in dynamic sealing or harsh chemical applications.

EPDM (Ethylene Propylene Diene Monomer): Provides excellent resistance to ozone, UV radiation, weathering, and polar fluids like water, steam, and some brake fluids. EPDM is not recommended for use with petroleum-based oils and fuels.

Fluorosilicone (FVMQ): Combines the broad temperature range of silicone with improved fuel and oil resistance, making it suitable for aerospace and automotive applications where both extreme temperatures and chemical exposure are present.

Other specialized materials include Kalrez (FFKM) for ultimate chemical resistance in very harsh environments, and Aflas (TFE/P) for excellent resistance to steam, acids, and bases. The selection process should always involve a thorough evaluation of the application's requirements to ensure optimal seal performance and longevity.

How do I choose the right size O-ring for my application?

Please provide a complete question so I can answer it.

What are the benefits of using rubber edging for edge protection?

Rubber edging offers numerous benefits for edge protection due to its inherent properties. Its flexibility allows it to conform to various shapes and curves, providing comprehensive coverage for sharp or abrasive edges on a wide range of materials, including metal, glass, and plastic. This adaptability makes it suitable for diverse applications, from industrial machinery to automotive parts and furniture.

One of the primary advantages of rubber edging is its excellent shock absorption capabilities. It effectively dampens impacts, protecting both the edge and any objects or individuals that may come into contact with it. This reduces the risk of damage, scratches, or injuries. Furthermore, rubber is highly durable and resistant to wear and tear, abrasion, and various environmental factors like UV radiation, ozone, and extreme temperatures. This ensures a long lifespan and consistent performance, even in harsh conditions.

Rubber edging also provides good sealing properties, preventing the ingress of dust, moisture, and other contaminants, which is crucial for protecting sensitive components or maintaining cleanliness. Its anti-slip properties can enhance safety by providing a secure grip on edges, reducing the likelihood of items sliding off. Finally, the material's aesthetic appeal can improve the appearance of products or structures by providing a clean, finished look while concealing rough edges.

How do edge protection grommets prevent wire abrasion?

Edge protection grommets, typically made from flexible materials like rubber or plastic, are crucial components in safeguarding wires, cables, and hoses from abrasion and damage. Their primary function is to provide a protective barrier when these components pass through sharp-edged openings in panels, enclosures, or bulkheads.

The mechanism by which they prevent wire abrasion is multifaceted:1. **Cushioning and Insulation:** Grommets act as a soft cushion, absorbing the friction that would otherwise occur between the wire and the sharp edge of the opening. This cushioning effect distributes pressure evenly, preventing localized stress points that could lead to wear and tear on the wire's insulation.

2. **Smooth Surface:** The inner surface of a grommet is designed to be smooth and free of burrs or irregularities. This smooth contact surface minimizes friction and allows the wire to pass through without catching or snagging, which can cause nicks or cuts in the insulation.

3. **Secure Fit:** Grommets are designed to fit snugly into the panel opening, creating a stable and secure passage for the wire. This secure fit prevents the wire from shifting or rubbing against the sharp edge, especially in environments subject to vibration or movement.

4. **Environmental Protection:** Beyond abrasion, grommets also offer a degree of environmental protection. They can help seal the opening, preventing dust, moisture, and other contaminants from entering the enclosure and potentially damaging the wires or the internal components. Some specialized grommets are also designed for specific environmental challenges, such as high temperatures or chemical exposure.In summary, edge protection grommets are a simple yet effective solution for preventing wire abrasion by providing a cushioned, smooth, and secure passage, thereby extending the lifespan of wires and ensuring the reliability of electrical and mechanical systems.

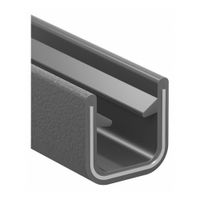

What factors should be considered when selecting rubber edge trim seals?

When selecting rubber edge trim seals, several factors should be considered to ensure optimal performance and longevity. Firstly, the application environment is crucial. This includes exposure to extreme temperatures, UV radiation, chemicals, and moisture, as these can affect the material's durability and sealing capabilities. Secondly, the material composition of the rubber is vital. Common materials include EPDM, PVC, neoprene, and silicone, each offering different properties in terms of flexibility, chemical resistance, and temperature range. The chosen material must be compatible with the environment it will be used in.

Thirdly, the design and profile of the trim seal are important for a secure and effective seal. This includes the grip range, which should match the thickness of the edge it will be applied to, and the bulb or sealing profile, which determines how well it will compress and create a barrier. Fourthly, installation methods should be considered, as some trims require adhesives while others are push-on. Finally, regulatory requirements and industry standards specific to the application should be met to ensure safety and compliance.

How do hole plugs work to seal panel openings?

Hole plugs are designed to seal unwanted or unused panel openings, providing protection against dust, moisture, and other environmental factors, while also offering aesthetic finishing. They typically consist of a cap and flexible fins or barbs on the shank. When inserted into a pre-drilled hole, the fins compress and then expand against the inner wall of the panel, creating a secure, friction-fit seal. Some designs may feature a stepped or ribbed shank to accommodate varying panel thicknesses, while others might include a sealing ring or gasket for enhanced protection against liquids. They are commonly made from durable materials such as nylon, plastic, or rubber, chosen for their resilience, chemical resistance, and insulating properties. Installation is usually quick and tool-free, making them a convenient solution for various applications across industries like electronics, automotive, and manufacturing.

What are the advantages of using nylon bushings for wire protection?

Nylon bushings offer several advantages for wire protection. They provide excellent insulation, preventing electrical shorts and protecting wires from abrasion and sharp edges. Their flexible yet durable nature allows for easy installation while ensuring long-lasting protection. Nylon is also resistant to many chemicals, oils, and solvents, making these bushings suitable for a wide range of environments. Furthermore, they can withstand a broad temperature range, maintaining their protective properties in various conditions. Their lightweight and cost-effective design also makes them an attractive solution for many applications, from automotive and electronics to industrial machinery, ensuring the longevity and safety of electrical wiring.

How do I install rubber edge trim seals on panels?

Installing rubber edge trim seals on panels is a straightforward process that provides both protection and a finished look. These seals are commonly used to cover sharp edges, prevent rattling, and create a weather-tight seal.

Here's a general guide to installing them:1. **Prepare the Surface**: Ensure the panel edge is clean, dry, and free of any debris, grease, or rust. Use a degreaser or alcohol if necessary. A clean surface ensures proper adhesion and a secure fit.

2. **Measure and Cut**: Measure the length of the edge where the trim will be installed. Cut the rubber trim seal to the measured length using a sharp utility knife or heavy-duty scissors. It's often better to cut slightly longer and trim to fit precisely later.

3. **Start Installation**: Begin at one end of the panel. Align the U-channel of the trim with the edge of the panel.

4. **Press and Secure**: Firmly press the trim onto the edge of the panel. Many rubber trims have an internal grip or a built-in adhesive. For trims with an internal grip, simply push it onto the edge until it seats securely. For trims with adhesive, peel back the protective liner as you go, pressing the trim firmly into place. Work your way along the entire length of the panel.

5. **Corners and Curves**: For corners, you can either miter the trim at a 45-degree angle for a cleaner look or carefully bend the trim around the corner. Some trims are designed to flex around curves easily. For sharper bends, you might need to make small relief cuts on the inner side of the trim, being careful not to cut all the way through.

6. **Finishing Touches**: Once installed, run your hand along the entire length of the trim to ensure it is fully seated and securely attached. Trim any excess material for a neat finish.Following these steps will help you achieve a professional and durable installation of rubber edge trim seals on your panels.

What are the common applications for edge protection grommets?

Edge protection grommets are versatile components used across various industries to safeguard wires, cables, hoses, and pipes from sharp edges, friction, and abrasion. Their primary function is to create a smooth, protective barrier, preventing damage that could lead to costly repairs, equipment failure, or safety hazards.

Common applications include: * **Automotive Industry:** Used extensively in vehicles to protect wiring harnesses, fuel lines, and brake lines as they pass through metal panels, reducing vibration-induced wear and tear.

* **Electronics and Electrical Enclosures:** Essential for insulating and protecting sensitive electronic components and their associated wiring from sharp chassis edges, ensuring longevity and preventing short circuits.

* **Aerospace:** In aircraft, grommets are critical for routing hydraulic lines, electrical wiring, and control cables through bulkheads and structural components, providing vibration dampening and chafe protection in demanding environments.

* **Manufacturing and Industrial Machinery:** Applied to protect moving parts, pneumatic and hydraulic lines, and electrical conduits in industrial equipment, machine tools, and robotics, extending the lifespan of critical components.

* **Construction:** Utilized in building structures to protect electrical cables, plumbing pipes, and HVAC ducting where they pass through framing or openings, preventing damage during installation and use.

* **Home Appliances:** Found in refrigerators, washing machines, and other appliances, protecting internal wiring and hosing from vibration and sharp metal edges.

* **Furniture and Office Equipment:** Employed to protect power cords and data cables where they exit desks, cabinets, or computer workstations, maintaining an organized and safe environment.By preventing wear, tear, and short circuits, edge protection grommets contribute significantly to the reliability, safety, and operational efficiency of numerous products and systems.

How do I maintain and replace O-rings to ensure effective sealing?

Maintaining and replacing O-rings are crucial for ensuring effective sealing in various applications. Proper maintenance begins with regular inspection for signs of wear, damage, or degradation, such as cracks, nicks, swelling, or hardening. Clean the O-ring and its groove thoroughly before installation or reinstallation to prevent contamination that could compromise the seal. Always ensure the O-ring is compatible with the fluid or gas it will be exposed to, considering temperature and pressure conditions, as incorrect material can lead to premature failure.

When replacing an O-ring, first, carefully remove the old one, avoiding any damage to the groove or surrounding components. Clean the groove and inspect it for any imperfections. Lubricate the new O-ring with a compatible lubricant before installation. This helps prevent twisting or pinching during assembly and reduces friction, extending the O-ring's lifespan. Install the O-ring correctly into its groove, ensuring it is not stretched or compressed excessively. Over-stretching can reduce its cross-sectional area and sealing effectiveness, while over-compression can lead to permanent deformation. Finally, tighten fasteners to the recommended torque specifications to achieve proper compression without over-stressing the O-ring. Regular maintenance and careful replacement procedures are key to maximizing O-ring life and maintaining a reliable seal.