Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Floor Wall Other Surface Finishes

- Paint Equipment Supplies

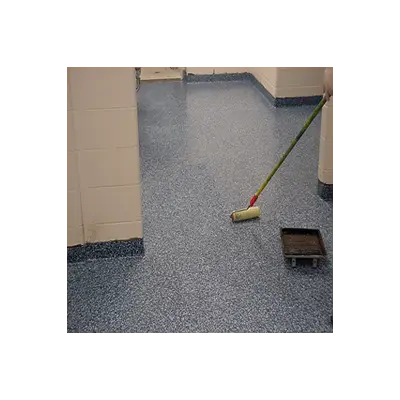

- Floor Coatings

.....Read More

Frequently Asked Questions

What are the benefits of using floor coatings?

Floor coatings offer numerous benefits, enhancing both the functionality and aesthetics of various spaces. Firstly, they provide superior protection against wear and tear, extending the lifespan of the flooring by shielding it from scratches, stains, and chemical spills. This is particularly beneficial in industrial and commercial settings where floors are subject to heavy traffic and harsh conditions.

Secondly, floor coatings improve safety by offering slip-resistant surfaces, reducing the risk of accidents in wet or oily environments. This is crucial in workplaces to ensure compliance with safety regulations and protect employees.

Aesthetically, floor coatings can transform the appearance of a space. Available in a variety of colors and finishes, they can enhance the visual appeal of both residential and commercial interiors, creating a clean and polished look.

Additionally, floor coatings are easy to clean and maintain. Their smooth, non-porous surfaces prevent the accumulation of dust, dirt, and bacteria, making them ideal for environments that require high hygiene standards, such as hospitals and food processing facilities.

Moreover, certain types of floor coatings, like epoxy, offer excellent resistance to temperature fluctuations and moisture, making them suitable for use in areas exposed to extreme conditions.

Finally, floor coatings can be cost-effective in the long run. By reducing maintenance needs and preventing damage, they lower repair and replacement costs. This makes them a wise investment for property owners looking to enhance durability and reduce long-term expenses.

How do I apply epoxy floor coatings?

1. **Preparation**:

- **Clean the Surface**: Remove all furniture and thoroughly clean the floor. Sweep and vacuum to eliminate dust and debris.

- **Repair Damages**: Patch any cracks or holes with a suitable filler and allow it to dry.

- **Etch the Concrete**: Use an etching solution to open up the concrete pores for better adhesion. Rinse thoroughly and let it dry completely.

- **Test for Moisture**: Ensure the floor is dry by taping a plastic sheet overnight. If condensation forms, the floor needs more drying time.

2. **Gather Materials**:

- Epoxy resin and hardener

- Paint roller and brushes

- Mixing bucket and drill with a mixing paddle

- Protective gear (gloves, goggles, mask)

3. **Mixing Epoxy**:

- Follow the manufacturer’s instructions for mixing the resin and hardener. Use a drill with a mixing paddle for a consistent blend.

- Mix only enough epoxy that can be applied within the pot life (working time).

4. **Application**:

- **Prime the Floor**: Apply a thin coat of epoxy primer using a roller. This enhances adhesion and seals the surface.

- **Apply the Base Coat**: Pour the mixed epoxy onto the floor in small sections. Use a roller to spread it evenly, maintaining a wet edge to avoid lap marks.

- **Add Decorative Flakes (Optional)**: Sprinkle decorative flakes onto the wet epoxy for texture and design.

- **Apply the Top Coat**: Once the base coat is dry, apply a clear top coat for added durability and shine.

5. **Curing**:

- Allow the epoxy to cure as per the manufacturer’s instructions, typically 24-72 hours, before walking on it and a full week before heavy use.

6. **Final Inspection**:

- Check for any missed spots or imperfections and touch up if necessary.

What is the best type of floor coating for a garage?

The best type of floor coating for a garage is typically epoxy coating. Epoxy is a durable, long-lasting, and aesthetically pleasing option that provides a high level of protection against stains, chemicals, and abrasions. It consists of a resin and a hardener that, when mixed, create a rigid plastic material that bonds exceptionally well to concrete surfaces.

Epoxy coatings are highly resistant to oil, gasoline, antifreeze, and other chemicals commonly found in garages, making them ideal for automotive workspaces. They also offer excellent resistance to wear and tear from vehicle traffic and heavy equipment. The seamless surface of epoxy is easy to clean and maintain, reducing dust and debris accumulation.

Additionally, epoxy coatings can be customized with various colors, patterns, and finishes, including anti-slip additives for enhanced safety. This allows homeowners to tailor the appearance of their garage floor to their personal preferences while ensuring functionality.

While epoxy is a top choice, it requires proper surface preparation and professional installation to ensure optimal performance and longevity. The concrete must be clean, dry, and free of cracks or damage before application. Once applied, epoxy coatings can last for many years with minimal maintenance.

Other options like polyurethane and polyaspartic coatings offer similar benefits but may come at a higher cost or require specific application conditions. However, for most residential garages, epoxy remains the most cost-effective and reliable choice, balancing durability, aesthetics, and ease of maintenance.

How long do floor coatings last?

The longevity of floor coatings depends on several factors, including the type of coating, the environment in which it is applied, and the level of maintenance it receives. Here is a breakdown of common floor coatings and their typical lifespan:

1. **Epoxy Coatings**: Epoxy coatings are popular for their durability and resistance to wear and chemicals. In residential settings, they can last 5 to 10 years, while in commercial or industrial environments, they may last 2 to 5 years due to heavier traffic and usage.

2. **Polyurethane Coatings**: Known for their flexibility and resistance to abrasion, polyurethane coatings can last 5 to 8 years in residential areas. In commercial settings, they might last 3 to 5 years, depending on the level of foot traffic and maintenance.

3. **Polyaspartic Coatings**: These coatings are highly durable and resistant to UV rays, making them suitable for both indoor and outdoor applications. They can last 7 to 10 years in residential areas and 5 to 7 years in commercial settings.

4. **Acrylic Coatings**: Acrylic coatings are less durable than epoxy or polyurethane but are easier to apply and recoat. They typically last 1 to 3 years, making them more suitable for areas with lighter traffic.

5. **Concrete Stains and Sealers**: These coatings penetrate the surface and provide a decorative finish. They can last 3 to 5 years, depending on the level of exposure to elements and traffic.

Regular maintenance, such as cleaning and reapplying topcoats, can extend the life of floor coatings. Environmental factors like temperature fluctuations, moisture, and exposure to chemicals also play a significant role in determining the lifespan of a floor coating.

Can floor coatings be applied to outdoor surfaces?

Yes, floor coatings can be applied to outdoor surfaces. These coatings are designed to protect and enhance the appearance of outdoor areas such as patios, driveways, walkways, and pool decks. Outdoor floor coatings are formulated to withstand various environmental conditions, including UV exposure, temperature fluctuations, moisture, and heavy foot or vehicle traffic.

There are several types of floor coatings suitable for outdoor use:

1. **Epoxy Coatings**: While traditionally used indoors, some epoxy formulations are designed for outdoor use. They provide a durable, glossy finish that is resistant to chemicals and abrasion. However, they may yellow over time due to UV exposure unless UV-stable versions are used.

2. **Polyurethane Coatings**: These are more UV-stable than epoxy and offer excellent resistance to weathering, making them suitable for outdoor applications. They provide a flexible, durable finish that can handle temperature changes and resist cracking.

3. **Acrylic Coatings**: Acrylic-based coatings are popular for outdoor use due to their UV resistance and ability to withstand weather conditions. They are available in various colors and finishes, providing aesthetic versatility.

4. **Polyaspartic Coatings**: Known for their rapid curing time and UV stability, polyaspartic coatings are ideal for outdoor surfaces. They offer high durability and resistance to chemicals and abrasion.

5. **Concrete Sealers**: These are often used to protect and enhance concrete surfaces. They penetrate the surface to provide protection against moisture, stains, and wear.

When applying floor coatings outdoors, surface preparation is crucial. The surface must be clean, dry, and free of any contaminants to ensure proper adhesion. Additionally, weather conditions should be considered, as extreme temperatures or humidity can affect the application and curing process. Properly applied, outdoor floor coatings can extend the life of the surface and enhance its appearance.

How do I maintain and clean coated floors?

To maintain and clean coated floors effectively, follow these steps:

1. **Regular Sweeping/Dust Mopping**: Use a soft-bristle broom or a microfiber dust mop daily to remove dirt and debris. This prevents scratches and maintains the floor's shine.

2. **Vacuuming**: Use a vacuum cleaner with a hard floor setting to remove fine dust and particles. Avoid using a beater bar as it can damage the coating.

3. **Damp Mopping**: Use a damp mop with a pH-neutral cleaner specifically designed for coated floors. Avoid excessive water as it can seep into seams and cause damage.

4. **Spot Cleaning**: Immediately clean spills with a soft cloth or paper towel to prevent staining. Use a mild cleaner if necessary.

5. **Avoid Harsh Chemicals**: Do not use bleach, ammonia, or abrasive cleaners as they can strip the coating and dull the finish.

6. **Use Floor Mats**: Place mats at entryways to reduce dirt and moisture tracked onto the floor. Ensure mats are non-slip and do not have a rubber backing that can discolor the floor.

7. **Furniture Pads**: Attach felt pads to the bottom of furniture legs to prevent scratches and dents.

8. **Regular Polishing**: Depending on the type of coating, apply a suitable floor polish or wax periodically to restore shine and protect the surface.

9. **Professional Maintenance**: Schedule professional cleaning and recoating as recommended by the floor manufacturer to maintain the integrity and appearance of the coating.

10. **Avoid High Heels and Sharp Objects**: These can cause dents and scratches on the floor surface.

By following these steps, you can ensure your coated floors remain clean, shiny, and in good condition for years.

Are floor coatings resistant to chemicals and stains?

Yes, floor coatings can be resistant to chemicals and stains, but the level of resistance depends on the type of coating used. Epoxy coatings, for example, are highly resistant to a wide range of chemicals, including acids, alkalis, solvents, and oils, making them ideal for industrial and commercial environments where chemical exposure is common. Polyurethane coatings also offer good chemical resistance and are particularly effective against abrasion and impact, making them suitable for areas with heavy foot traffic or machinery.

Polyaspartic coatings provide excellent chemical and stain resistance, along with rapid curing times, which makes them a popular choice for both commercial and residential applications. They are particularly effective against oil, grease, and other common household stains.

Acrylic coatings, while less durable than epoxy or polyurethane, still offer moderate resistance to chemicals and stains and are often used in areas with lighter traffic or where aesthetics are a priority.

The effectiveness of a floor coating in resisting chemicals and stains also depends on the quality of the application and the specific formulation of the product. Proper surface preparation and application are crucial to ensure maximum performance and longevity of the coating.

In summary, while many floor coatings offer resistance to chemicals and stains, the degree of resistance varies based on the type of coating and its application. Selecting the right coating for the specific environment and anticipated exposure is essential to achieving the desired level of protection.