Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Electrical

- Industrial Controls Automation And Machine Safety

- Relays

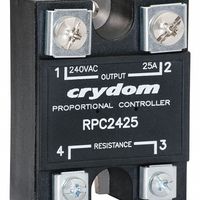

- Solid State Relays

.....Read More

Frequently Asked Questions

What is a solid-state relay and how does it work?

A solid-state relay (SSR) is an electronic switching device that uses semiconductor components to switch on or off the flow of electricity in a circuit. Unlike electromechanical relays, SSRs have no moving parts, which enhances their reliability and longevity.

An SSR typically consists of three main parts: an input circuit, a control circuit, and an output circuit. The input circuit receives a low-voltage control signal, which can be from a microcontroller or other control device. This signal activates the control circuit, which is often an opto-isolator. The opto-isolator provides electrical isolation between the input and output, enhancing safety and preventing interference.

The control circuit then triggers the output circuit, which is usually composed of power semiconductor devices like thyristors, triacs, or transistors. These components handle the high-voltage and high-current load. When the control signal is applied, the semiconductor devices switch on, allowing current to flow through the load. When the control signal is removed, the devices switch off, stopping the current flow.

SSRs offer several advantages over traditional relays, including faster switching times, longer operational life, and silent operation. They are also more resistant to shock and vibration, making them suitable for harsh environments. However, SSRs can generate heat and may require heat sinks for thermal management. They are also more expensive than electromechanical relays and may have higher on-state voltage drops, leading to power losses.

Overall, solid-state relays are ideal for applications requiring high-speed switching, frequent on/off cycles, and enhanced durability, such as in industrial automation, HVAC systems, and lighting controls.

What are the advantages of using solid-state relays over mechanical relays?

Solid-state relays (SSRs) offer several advantages over mechanical relays:

1. **Longevity and Reliability**: SSRs have no moving parts, which reduces wear and tear, leading to a longer lifespan and higher reliability compared to mechanical relays that suffer from contact erosion and mechanical fatigue.

2. **Silent Operation**: SSRs operate silently as they do not have a physical contact mechanism that clicks or makes noise, unlike mechanical relays.

3. **Fast Switching**: SSRs can switch on and off much faster than mechanical relays, making them suitable for applications requiring rapid cycling.

4. **Reduced Electromagnetic Interference (EMI)**: The absence of arcing and bouncing contacts in SSRs minimizes EMI, which is beneficial in sensitive electronic environments.

5. **Vibration and Shock Resistance**: SSRs are more resistant to vibration and shock, as they lack mechanical components that can be displaced or damaged.

6. **Low Power Consumption**: SSRs typically consume less power to operate, as they do not require energy to move physical contacts.

7. **Consistent Performance**: SSRs provide consistent performance over time without the degradation that mechanical contacts experience.

8. **No Contact Bounce**: SSRs eliminate contact bounce, ensuring more precise and reliable switching.

9. **Compact Size**: SSRs are often more compact than mechanical relays, allowing for more efficient use of space in electronic designs.

10. **Wide Range of Applications**: SSRs can handle a wide range of voltages and currents, making them versatile for various applications.

11. **Improved Safety**: SSRs reduce the risk of sparking and arcing, enhancing safety in explosive or flammable environments.

These advantages make SSRs a preferred choice in many modern applications, particularly where reliability, speed, and noise reduction are critical.

How do you choose the right solid-state relay for an application?

1. **Load Type and Rating**: Determine the type of load (resistive, inductive, capacitive) and its power rating. Ensure the SSR can handle the load's current and voltage requirements.

2. **Switching Type**: Choose between zero-crossing (for resistive loads) and random turn-on (for inductive loads) switching types based on the load characteristics.

3. **Control Voltage**: Match the SSR's input control voltage with the available control signal in your application, whether it's AC or DC.

4. **Output Voltage and Current**: Ensure the SSR's output voltage and current ratings exceed the maximum expected load to provide a safety margin.

5. **Heat Dissipation**: Consider the thermal management requirements. SSRs generate heat, so check if a heat sink or fan is necessary to maintain optimal operating temperatures.

6. **Isolation Voltage**: Verify the isolation voltage rating between the input and output to ensure it meets safety standards for your application.

7. **Environmental Conditions**: Assess the operating environment, including temperature, humidity, and potential exposure to dust or chemicals. Choose an SSR with appropriate protection ratings (e.g., IP ratings).

8. **Mounting and Size**: Consider the physical size and mounting options (DIN rail, panel mount) to ensure compatibility with your system's design.

9. **Life Expectancy and Reliability**: Evaluate the SSR's expected lifespan and reliability, especially for critical applications, by checking manufacturer specifications and reviews.

10. **Cost and Availability**: Balance the cost with the required features and ensure the SSR is readily available from reliable suppliers.

11. **Regulatory Compliance**: Ensure the SSR complies with relevant industry standards and certifications (e.g., UL, CE) for safety and performance.

12. **Manufacturer Support**: Consider the level of technical support and warranty offered by the manufacturer for troubleshooting and maintenance.

What are the common applications of solid-state relays?

Solid-state relays (SSRs) are widely used in various applications due to their reliability, fast switching, and long lifespan. Common applications include:

1. **Industrial Automation**: SSRs are used in controlling motors, heaters, and lamps in automated systems. Their ability to handle high-frequency switching without wear makes them ideal for repetitive operations.

2. **HVAC Systems**: In heating, ventilation, and air conditioning systems, SSRs control compressors, fans, and pumps, providing precise temperature regulation and energy efficiency.

3. **Lighting Control**: SSRs are employed in dimming and switching lighting systems, especially in commercial and theatrical settings, due to their silent operation and ability to handle high inrush currents.

4. **Home Appliances**: They are used in ovens, washing machines, and other appliances for controlling heating elements and motors, offering improved safety and performance.

5. **Temperature Control**: SSRs are integral in temperature control systems for industrial ovens, plastic molding machines, and other equipment requiring precise thermal management.

6. **Power Supplies**: In uninterruptible power supplies (UPS) and other power management systems, SSRs provide reliable switching and load management.

7. **Telecommunications**: SSRs are used in telecom equipment for signal routing and protection, benefiting from their fast response and low electromagnetic interference.

8. **Medical Equipment**: In medical devices, SSRs ensure reliable operation of critical components like pumps and heaters, where mechanical relays might fail.

9. **Renewable Energy Systems**: SSRs are used in solar inverters and wind turbines for efficient power conversion and load management.

10. **Transportation**: In electric vehicles and railway systems, SSRs manage power distribution and control auxiliary systems, enhancing durability and performance.

These applications leverage the advantages of SSRs, such as no moving parts, reduced maintenance, and enhanced control precision, making them a preferred choice over traditional electromechanical relays in many scenarios.

How do you troubleshoot a solid-state relay?

1. **Visual Inspection**: Check for physical damage, overheating signs, or burnt components.

2. **Input Voltage Check**: Measure the control input voltage with a multimeter to ensure it matches the relay's specifications.

3. **Output Voltage Check**: With the relay activated, measure the output voltage to verify it is passing the correct voltage to the load.

4. **Load Connection**: Ensure the load is properly connected and within the relay's rated capacity.

5. **Control Signal**: Verify the control signal is present and correct. Check for proper polarity and amplitude.

6. **Continuity Test**: With the relay de-energized, check for continuity across the output terminals to ensure it is open. When energized, it should show continuity.

7. **Temperature Check**: Use an infrared thermometer to check for abnormal heating, which may indicate internal failure.

8. **LED Indicator**: If the relay has an LED indicator, ensure it lights up when the relay is activated.

9. **Noise and Vibration**: Listen for unusual noises or vibrations that may indicate mechanical issues.

10. **Isolation Test**: Perform an insulation resistance test between input and output to ensure proper isolation.

11. **Check for Short Circuits**: Inspect for any short circuits in the load or wiring that may affect relay operation.

12. **Replace if Necessary**: If the relay fails any of these tests, consider replacing it, as solid-state relays are not typically repairable.

13. **Consult Documentation**: Refer to the manufacturer's datasheet or manual for specific troubleshooting steps and specifications.

What are the differences between general-purpose and hazardous-location solid-state relays?

General-purpose solid-state relays (SSRs) and hazardous-location SSRs differ primarily in their design, application, and safety features.

1. **Design and Construction**:

- **General-Purpose SSRs**: These are designed for standard environments and typical industrial applications. They have basic insulation and protection suitable for non-hazardous areas.

- **Hazardous-Location SSRs**: These are specifically engineered to operate safely in environments with explosive gases, dust, or fibers. They feature enhanced insulation, robust enclosures, and are often certified to meet stringent safety standards like ATEX or IECEx.

2. **Materials and Components**:

- **General-Purpose SSRs**: Use standard materials that provide adequate performance in normal conditions.

- **Hazardous-Location SSRs**: Utilize materials that can withstand extreme conditions, such as corrosion-resistant metals and high-temperature plastics, to prevent ignition of flammable substances.

3. **Safety and Certification**:

- **General-Purpose SSRs**: Typically do not require special certifications beyond standard electrical safety.

- **Hazardous-Location SSRs**: Must be certified for use in specific hazardous zones. They undergo rigorous testing to ensure they do not produce sparks or excessive heat that could ignite hazardous materials.

4. **Applications**:

- **General-Purpose SSRs**: Used in applications like lighting control, heating, and motor control in non-hazardous environments.

- **Hazardous-Location SSRs**: Employed in industries such as oil and gas, chemical processing, and mining, where explosive atmospheres are present.

5. **Cost**:

- **General-Purpose SSRs**: Generally less expensive due to simpler design and materials.

- **Hazardous-Location SSRs**: More costly due to specialized design, materials, and certification processes.

How do time-delay solid-state relays function?

Time-delay solid-state relays (SSRs) function by using electronic components to control the timing and switching of electrical circuits without mechanical parts. They consist of an input circuit, a control circuit, and an output circuit. The input circuit receives a control signal, typically a low-voltage DC signal, which activates the relay.

The control circuit is the core of the time-delay function. It includes a timing mechanism, often implemented using a microcontroller or a timer IC, which determines the delay period. When the input signal is received, the control circuit starts the timing process. The delay can be set to a specific duration, ranging from milliseconds to several minutes, depending on the application.

Once the delay period elapses, the control circuit sends a signal to the output circuit. The output circuit typically uses a semiconductor device, such as a triac or a thyristor, to switch the load circuit on or off. This solid-state switching provides several advantages, including faster response times, longer lifespan, and reduced electrical noise compared to electromechanical relays.

Time-delay SSRs are used in applications where precise timing control is required, such as in industrial automation, HVAC systems, and lighting controls. They offer high reliability and are less susceptible to wear and tear, making them suitable for environments with frequent switching operations. Additionally, they provide isolation between the control and load circuits, enhancing safety and protecting sensitive control electronics from high voltages.