- Home

- Electrical

- Cables Conductors

- Instrumentation And Control Cables

.....Read More

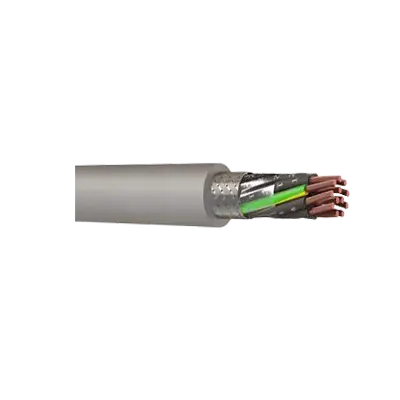

CY Multicore Screened Control Cable

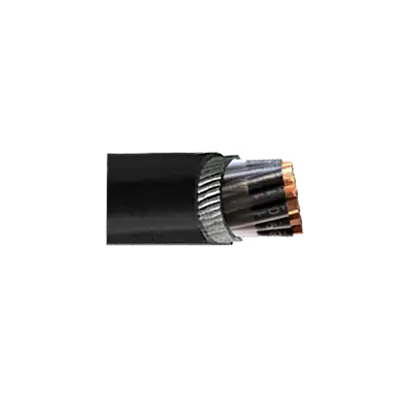

Multicore Control Cable - Armoured

Multicore Control Cable - Unarmoured

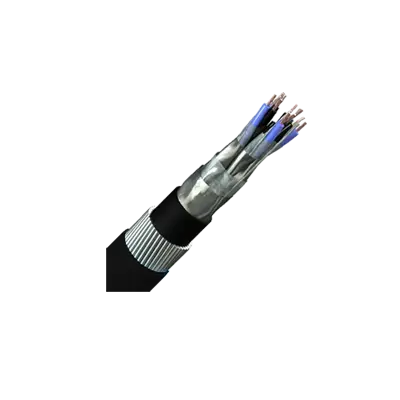

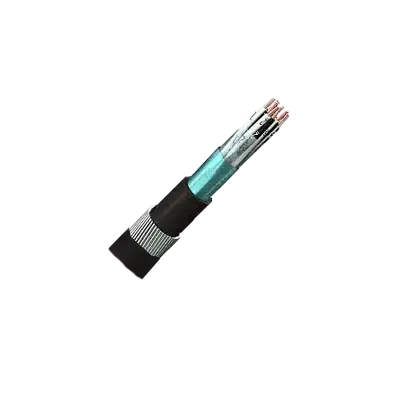

Overall & Individually Screened Armoured Instrumentation Cables

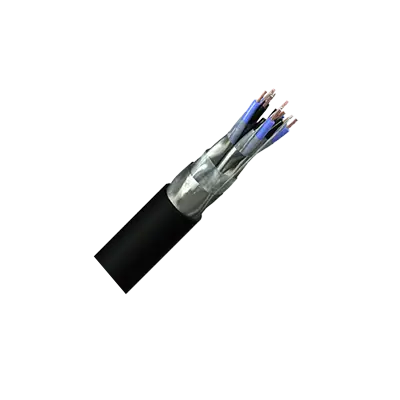

Overall & Individually Screened Unarmoured Instrumentation Cables

Overall Screened Armoured Instrumentation Cables

Overall Screened Unarmoured Instrumentation Cables

Frequently Asked Questions

What are instrumentation and control cables used for?

What are the key differences between instrumentation cables and control cables?

How do you select the right instrumentation and control cable for a specific application?

What are the common materials used in the construction of instrumentation and control cables?

How do shielding and insulation affect the performance of instrumentation and control cables?

What are the standards and certifications for instrumentation and control cables?

How do you install and maintain instrumentation and control cables to ensure optimal performance?