Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Electrical

- Cables Conductors

- Aluminium Aluminium Alloy Conductor

.....Read More

Frequently Asked Questions

What are the advantages of using aluminium conductors over copper?

Aluminium conductors offer several advantages over copper conductors:

1. **Cost-Effectiveness**: Aluminium is significantly cheaper than copper, making it a cost-effective choice for electrical wiring and power transmission. This cost advantage is particularly beneficial for large-scale projects and infrastructure.

2. **Weight**: Aluminium is about one-third the weight of copper, which reduces the overall weight of electrical systems. This is advantageous in applications where weight is a critical factor, such as in aerospace, automotive, and overhead power lines.

3. **Corrosion Resistance**: Aluminium naturally forms a protective oxide layer when exposed to air, which helps prevent further corrosion. This property makes aluminium conductors suitable for outdoor and marine environments.

4. **Flexibility**: Aluminium is more malleable and flexible than copper, allowing for easier installation and handling. This flexibility can be beneficial in complex wiring systems and in situations where conductors need to be bent or shaped.

5. **Thermal Expansion**: Aluminium has a higher coefficient of thermal expansion than copper, which can be advantageous in applications where temperature fluctuations are common. It allows the conductor to expand and contract without causing damage to the connections.

6. **Abundance**: Aluminium is more abundant in the Earth's crust than copper, ensuring a more stable supply and less susceptibility to market fluctuations.

7. **Recyclability**: Aluminium is highly recyclable, and recycling it requires only a fraction of the energy needed to produce new aluminium. This makes it an environmentally friendly option.

8. **Electrical Conductivity**: While copper has higher conductivity, aluminium's conductivity-to-weight ratio is favorable, making it efficient for long-distance power transmission where weight is a concern.

These advantages make aluminium conductors a preferred choice in many applications, despite copper's superior conductivity.

How does the conductivity of aluminium compare to copper?

Aluminium and copper are both widely used conductive materials, but they differ in several key aspects regarding conductivity. Copper is known for its superior electrical conductivity, which is approximately 58.7 million siemens per meter (S/m) at room temperature. Aluminium, on the other hand, has a lower electrical conductivity of about 36 million S/m. This means that copper conducts electricity more efficiently than aluminium.

However, aluminium has a significant advantage in terms of weight. It is about one-third the density of copper, which makes it much lighter. This property is particularly beneficial in applications where weight is a critical factor, such as in overhead power lines and aircraft wiring. When considering conductivity relative to weight, aluminium becomes more competitive. For instance, an aluminium conductor with the same weight as a copper conductor can carry almost twice the electrical current.

In terms of thermal conductivity, copper also outperforms aluminium. Copper's thermal conductivity is about 401 watts per meter-kelvin (W/m·K), while aluminium's is around 237 W/m·K. This makes copper more effective in applications requiring efficient heat dissipation.

Cost is another factor where aluminium has an edge. Aluminium is generally less expensive than copper, which can make it a more cost-effective choice for large-scale projects or where budget constraints are significant.

In summary, while copper has superior electrical and thermal conductivity, aluminium offers advantages in terms of weight and cost. The choice between the two materials often depends on the specific requirements of the application, such as the importance of weight, cost considerations, and the need for maximum conductivity.

What are the common types of aluminium alloy conductors?

Common types of aluminum alloy conductors include:

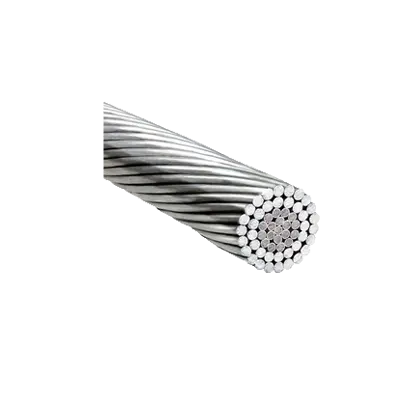

1. **All-Aluminum Conductor (AAC):** Made entirely of aluminum, AAC is used in urban areas where spans are short and supports are close together. It offers excellent conductivity and is lightweight, making it easy to handle and install.

2. **All-Aluminum Alloy Conductor (AAAC):** Composed of aluminum alloy, AAAC provides better strength-to-weight ratio compared to AAC. It is used in areas where higher strength is required without compromising conductivity.

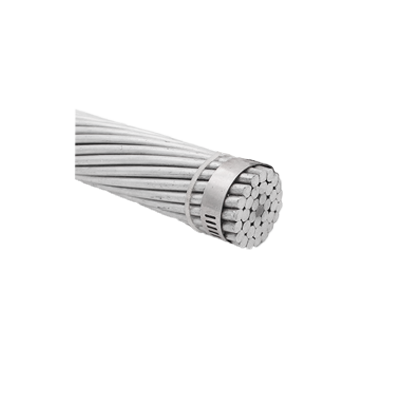

3. **Aluminum Conductor Steel Reinforced (ACSR):** This conductor consists of a core of steel strands surrounded by aluminum strands. The steel core provides high tensile strength, making ACSR suitable for long spans and areas prone to high mechanical stress.

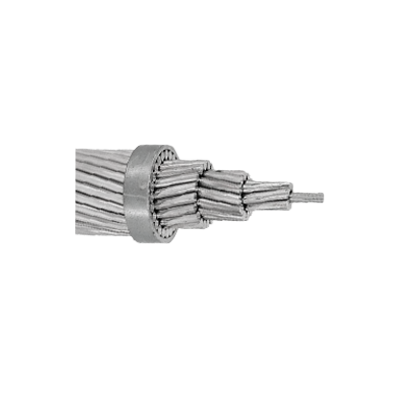

4. **Aluminum Conductor Alloy Reinforced (ACAR):** ACAR combines aluminum alloy strands with a core of aluminum alloy, offering a balance between strength and conductivity. It is used in applications requiring both high strength and good conductivity.

5. **Aluminum Conductor Composite Reinforced (ACCR):** Featuring a composite core, ACCR is designed for high-temperature applications and offers superior strength and conductivity. It is used in areas where traditional conductors would sag excessively under high temperatures.

6. **Aluminum Conductor Composite Core (ACCC):** With a carbon or glass fiber composite core, ACCC provides high strength and low sag characteristics. It is ideal for upgrading existing lines without changing tower structures.

These conductors are chosen based on factors like mechanical strength, conductivity, weight, and environmental conditions. Each type serves specific needs in power transmission and distribution, ensuring efficient and reliable electricity delivery.

How do aluminium conductors perform in terms of corrosion resistance?

Aluminium conductors exhibit good corrosion resistance, primarily due to the formation of a thin, protective oxide layer on their surface when exposed to air. This aluminium oxide layer is highly stable and adherent, preventing further oxidation and protecting the underlying metal from environmental factors. This natural passivation makes aluminium conductors suitable for various applications, including outdoor and marine environments, where they are exposed to moisture and other corrosive elements.

However, aluminium's corrosion resistance can be compromised in certain conditions. In environments with high chloride concentrations, such as coastal areas, aluminium can suffer from pitting corrosion. Additionally, when aluminium is in contact with dissimilar metals, galvanic corrosion can occur, especially if the other metal is more noble. This is often mitigated by using appropriate insulating materials or coatings to prevent direct metal-to-metal contact.

Aluminium conductors are also susceptible to crevice corrosion in areas where moisture can be trapped, such as under fasteners or in joints. Proper design and installation practices, including the use of sealants and protective coatings, can help minimize these risks.

Overall, while aluminium conductors have inherent corrosion resistance due to their oxide layer, their performance can be influenced by environmental conditions and material interactions. Proper material selection, design considerations, and protective measures are essential to ensure their long-term durability and performance in corrosive environments.

What are the applications of aluminium conductors in electrical systems?

Aluminium conductors are widely used in electrical systems due to their favorable properties such as low cost, lightweight, and good conductivity. Here are some key applications:

1. **Overhead Power Lines**: Aluminium conductors are extensively used in overhead power transmission and distribution lines. Their lightweight nature reduces the structural support requirements, making them ideal for long-distance power transmission.

2. **Busbars**: In electrical substations and industrial plants, aluminium busbars are used for distributing power. They offer a cost-effective alternative to copper while providing adequate conductivity and mechanical strength.

3. **Cables**: Aluminium is used in various types of cables, including power cables, service drop cables, and building wire. Its lightweight nature makes it easier to handle and install, especially in large-scale projects.

4. **Transformer Windings**: Aluminium is used in transformer windings due to its good conductivity and cost-effectiveness. It helps in reducing the overall weight and cost of transformers.

5. **Motor Windings**: In some cases, aluminium is used in motor windings, particularly in large motors where weight reduction is crucial.

6. **Aerial Bundled Cables (ABC)**: These are used for overhead power distribution in urban and rural areas. Aluminium conductors in ABC systems help in reducing power theft and improving safety.

7. **Underground Cables**: Aluminium conductors are also used in underground power cables, providing a balance between cost and performance.

8. **Renewable Energy Systems**: Aluminium conductors are used in solar and wind power systems for connecting panels and turbines to the grid, benefiting from their corrosion resistance and lightweight properties.

9. **Building Wiring**: In residential and commercial buildings, aluminium wiring is used for electrical installations, offering a cost-effective alternative to copper.

These applications leverage aluminium's advantages, such as its abundance, recyclability, and resistance to corrosion, making it a preferred choice in various electrical systems.

How do you join or connect aluminium conductors safely?

To join or connect aluminum conductors safely, follow these steps:

1. **Preparation**: Ensure the power is off. Clean the aluminum conductor ends using a wire brush to remove oxidation. This ensures a good electrical connection.

2. **Use of Anti-Oxidant Compound**: Apply an anti-oxidant compound, such as Noalox or Penetrox, to the cleaned conductor ends. This prevents future oxidation and enhances conductivity.

3. **Connector Selection**: Choose connectors specifically designed for aluminum, such as aluminum-to-aluminum or aluminum-to-copper connectors. These are often marked with "AL" or "AL/CU" to indicate compatibility.

4. **Mechanical Connectors**: Use mechanical connectors like split-bolt connectors, compression connectors, or set-screw connectors. Ensure they are rated for aluminum conductors.

5. **Compression Connectors**: If using compression connectors, select the correct die and tool for crimping. Follow the manufacturer's instructions for crimping to ensure a secure connection.

6. **Torque Specifications**: For set-screw connectors, tighten screws to the manufacturer's specified torque using a torque wrench. This ensures a secure connection without damaging the conductor.

7. **Insulation**: After making the connection, insulate it properly using electrical tape or heat-shrink tubing to prevent exposure to moisture and other environmental factors.

8. **Inspection**: Inspect the connection for any visible defects or loose strands. Ensure the connection is tight and secure.

9. **Testing**: Once the connection is made, test it for continuity and resistance to ensure it is functioning correctly.

10. **Regular Maintenance**: Periodically check the connections for signs of corrosion or loosening, especially in environments prone to temperature fluctuations.

By following these steps, you can ensure a safe and reliable connection of aluminum conductors.

What are the potential drawbacks of using aluminium conductors?

Aluminium conductors, while cost-effective and lightweight, have several drawbacks:

1. **Lower Conductivity**: Aluminium has about 61% of the electrical conductivity of copper, meaning larger diameters are needed to carry the same current, which can increase the size and weight of the installation.

2. **Thermal Expansion**: Aluminium expands and contracts more than copper when exposed to temperature changes. This can lead to loosening of connections over time, increasing the risk of overheating and potential fire hazards.

3. **Oxidation**: Aluminium forms an oxide layer when exposed to air, which is non-conductive. This can increase resistance at connections, leading to heat buildup and potential failure if not properly managed with anti-oxidation compounds.

4. **Mechanical Strength**: Aluminium is less ductile and has lower tensile strength compared to copper, making it more prone to breaking under mechanical stress, especially in applications requiring frequent bending or movement.

5. **Creep**: Aluminium is more susceptible to creep, a slow deformation under mechanical stress, which can lead to loosening of connections over time, necessitating regular maintenance and retightening.

6. **Corrosion**: In certain environments, especially where moisture is present, aluminium can corrode, particularly when in contact with other metals, leading to galvanic corrosion.

7. **Installation Challenges**: Special tools and techniques are often required for installing aluminium wiring to ensure safe and reliable connections, which can increase labor costs and complexity.

8. **Compatibility Issues**: Aluminium conductors may not be compatible with existing copper wiring systems without special connectors, potentially complicating upgrades or repairs.

9. **Safety Concerns**: Historical issues with aluminium wiring in residential applications have led to safety concerns, although modern alloys and installation practices have mitigated many of these risks.