Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

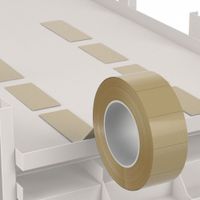

- Adhesives Sealants And Tape

- Tape

- Surface Protection Tape

- Slick Surface Tape Tape Shapes

.....Read More

Frequently Asked Questions

What are the main applications of PTFE and UHMW tapes?

PTFE (Polytetrafluoroethylene) and UHMW (Ultra-High Molecular Weight Polyethylene) tapes are specialized materials used in various industrial and commercial applications due to their unique properties.

**PTFE Tapes:**

1. **Sealing and Insulation:** PTFE tapes are widely used for sealing pipe threads in plumbing due to their excellent chemical resistance and ability to withstand high temperatures. They provide a leak-proof seal and prevent corrosion.

2. **Non-Stick Applications:** In industries like food processing and packaging, PTFE tapes are used on heat-sealing machines and conveyor belts to prevent sticking and ensure smooth operation.

3. **Electrical Insulation:** Due to their high dielectric strength, PTFE tapes are used for insulating electrical components and wires, especially in high-frequency applications.

4. **Chemical Resistance:** PTFE tapes are employed in environments exposed to aggressive chemicals, as they resist most acids and bases.

5. **Low Friction Surfaces:** They are used to reduce friction in machinery, providing a smooth, non-stick surface that enhances the lifespan of moving parts.

**UHMW Tapes:**

1. **Wear Resistance:** UHMW tapes are used in applications requiring high abrasion resistance, such as lining chutes, hoppers, and conveyor systems to reduce wear and tear.

2. **Noise Reduction:** They are applied to reduce noise in machinery by dampening vibrations and providing a smooth, quiet operation.

3. **Impact Resistance:** UHMW tapes are used in areas subject to impact, as they absorb shock and protect surfaces from damage.

4. **Low Friction Applications:** Similar to PTFE, UHMW tapes provide a low-friction surface, ideal for sliding applications in industrial settings.

5. **Protective Coatings:** They serve as protective layers on surfaces prone to scratching or damage, extending the life of equipment and components.

Both PTFE and UHMW tapes are integral in enhancing performance, reducing maintenance, and extending the lifespan of equipment across various industries.

How do PTFE and UHMW tapes reduce friction in industrial equipment?

PTFE (Polytetrafluoroethylene) and UHMW (Ultra-High Molecular Weight Polyethylene) tapes are used in industrial equipment to reduce friction due to their unique properties.

PTFE tape is known for its low coefficient of friction, which is one of the lowest among solid materials. This property allows it to create a slick surface that minimizes resistance between moving parts. PTFE is also chemically inert, meaning it does not react with most chemicals, making it suitable for various industrial applications. Its ability to withstand high temperatures without degrading further enhances its utility in reducing friction in environments where heat is a factor.

UHMW tape, on the other hand, is characterized by its high impact strength and abrasion resistance. It has a low coefficient of friction similar to PTFE, which helps in reducing wear and tear on equipment. UHMW is particularly effective in applications involving heavy loads and high impact, as it can absorb shocks and resist surface damage. Its durability and resistance to wear make it ideal for use in conveyor systems, chutes, and other equipment where components are in constant motion.

Both tapes are easy to apply and can be used to line surfaces, create sliding surfaces, or wrap around components to reduce friction. By minimizing friction, these tapes help in extending the lifespan of equipment, reducing maintenance costs, and improving operational efficiency. They also contribute to energy savings by reducing the power required to move parts, thus enhancing the overall performance of industrial machinery.

What are the temperature and chemical resistance properties of PTFE tape?

PTFE tape, also known as Teflon tape, exhibits excellent temperature and chemical resistance properties, making it a popular choice for sealing pipe threads and other applications.

Temperature Resistance: PTFE tape can withstand a wide range of temperatures, typically from -268°C (-450°F) to 260°C (500°F). This broad temperature range allows it to be used in both extremely cold and hot environments without losing its sealing properties or structural integrity. Its thermal stability is due to the strong carbon-fluorine bonds in the PTFE polymer, which do not break down easily under heat.

Chemical Resistance: PTFE tape is highly resistant to a wide variety of chemicals, including acids, bases, solvents, and gases. It is virtually inert, meaning it does not react with most substances, which makes it suitable for use in chemically aggressive environments. This resistance is attributed to the non-polar nature of PTFE and its strong molecular structure, which prevents chemical interactions. However, it is worth noting that PTFE can be affected by molten alkali metals and some fluorinating agents at high temperatures.

Overall, the combination of high temperature and chemical resistance makes PTFE tape an ideal choice for sealing applications in plumbing, chemical processing, and other industries where exposure to harsh conditions is common.

How do UHMW tapes help in reducing noise and vibrations?

UHMW (Ultra-High Molecular Weight) tapes help reduce noise and vibrations primarily due to their unique material properties. UHMW is a type of polyethylene with extremely long chains, which gives it exceptional strength and durability. This material is known for its low coefficient of friction, high impact resistance, and excellent abrasion resistance, making it ideal for applications where noise and vibration reduction are critical.

1. **Low Friction Surface**: UHMW tapes provide a smooth, low-friction surface that minimizes the noise generated by moving parts. This is particularly useful in machinery and equipment where components slide against each other, as the tape reduces the frictional noise that typically occurs.

2. **Vibration Damping**: The material's inherent damping properties help absorb and dissipate vibrational energy. When applied to surfaces that experience frequent vibrations, UHMW tapes can significantly reduce the transmission of these vibrations, leading to quieter operation.

3. **Impact Resistance**: UHMW tapes can absorb impacts and shocks, which are common sources of noise in mechanical systems. By cushioning these impacts, the tapes prevent the sharp, loud noises that can occur when hard surfaces collide.

4. **Durability**: The high wear resistance of UHMW ensures that the tapes maintain their noise-reducing properties over time, even in harsh environments. This longevity means that they continue to provide effective noise and vibration reduction without frequent replacement.

5. **Versatility**: UHMW tapes can be applied to a wide range of surfaces and components, including conveyor systems, guide rails, and sliding doors, making them versatile solutions for noise and vibration issues across various industries.

Overall, UHMW tapes are an effective and durable solution for reducing noise and vibrations in mechanical systems, contributing to quieter and more efficient operations.

What are the benefits of using precut tape shapes over continuous rolls?

Precut tape shapes offer several advantages over continuous rolls:

1. **Time Efficiency**: Precut shapes eliminate the need for measuring and cutting, reducing preparation time and increasing productivity.

2. **Consistency**: They ensure uniformity in size and shape, which is crucial for applications requiring precision, such as in electronics or medical fields.

3. **Ease of Use**: Precut shapes are user-friendly, especially for those with limited dexterity or in high-volume environments, as they can be quickly applied without additional tools.

4. **Waste Reduction**: By providing exact sizes, precut shapes minimize waste compared to cutting from a roll, which often results in leftover scraps.

5. **Portability**: Precut shapes are typically packaged in a way that makes them easy to transport and store, ideal for on-the-go applications.

6. **Specialized Applications**: They are available in various shapes and sizes tailored for specific tasks, such as circles for sealing or strips for binding, enhancing their functionality.

7. **Improved Inventory Management**: With precut shapes, it is easier to track and manage inventory, as each piece is accounted for, reducing the risk of overuse or shortage.

8. **Enhanced Safety**: Eliminating the need for cutting tools reduces the risk of injury, making them safer for use in environments where safety is a priority.

9. **Professional Appearance**: Precut shapes provide a neat and professional finish, which is important in consumer-facing products or services.

10. **Cost-Effectiveness**: While the initial cost may be higher, the reduction in waste, time savings, and increased efficiency can lead to overall cost savings.

These benefits make precut tape shapes a preferred choice in various industries, from manufacturing to healthcare.

How do you apply and remove PTFE and UHMW tapes?

To apply PTFE and UHMW tapes, first ensure the surface is clean, dry, and free from dust, oil, or debris. Cut the tape to the desired length using scissors or a utility knife. Peel back a small section of the release liner to expose the adhesive. Align the tape with the application area, pressing it down gradually while removing the liner to avoid air bubbles. Use a roller or squeegee to apply even pressure, ensuring full adhesion.

To remove PTFE and UHMW tapes, gently lift one corner of the tape using a fingernail or a plastic scraper. Slowly peel back the tape at a low angle to minimize adhesive residue. If the tape is stubborn, apply heat using a hairdryer or heat gun to soften the adhesive, making removal easier. For any remaining adhesive residue, use a solvent like isopropyl alcohol or a commercial adhesive remover, applying it with a cloth and wiping clean.

What industries commonly use PTFE and UHMW tapes?

PTFE (Polytetrafluoroethylene) and UHMW (Ultra-High Molecular Weight Polyethylene) tapes are widely used across various industries due to their unique properties.

1. **Aerospace Industry**: PTFE tapes are used for their high-temperature resistance and low friction properties, making them ideal for wire harnessing, insulation, and sealing applications. UHMW tapes are used for their abrasion resistance and impact strength in protective linings and wear strips.

2. **Automotive Industry**: PTFE tapes are employed in gasket and seal applications due to their chemical resistance and non-stick properties. UHMW tapes are used for noise reduction, vibration damping, and as protective barriers against abrasion in vehicle interiors and exteriors.

3. **Electronics Industry**: PTFE tapes are used for insulation and as a dielectric material in electronic components due to their excellent electrical properties. UHMW tapes are used for their durability and low friction in moving parts and protective coverings.

4. **Food Processing Industry**: PTFE tapes are used for their non-stick and food-safe properties in conveyor belts and sealing applications. UHMW tapes are used for their wear resistance and ease of cleaning in food handling and processing equipment.

5. **Medical Industry**: PTFE tapes are used in medical devices and equipment for their biocompatibility and chemical resistance. UHMW tapes are used for their low friction and high wear resistance in prosthetics and orthopedic devices.

6. **Packaging Industry**: PTFE tapes are used in heat sealing machines for their non-stick and heat-resistant properties. UHMW tapes are used for their durability and low friction in conveyor systems and packaging machinery.

7. **Textile Industry**: PTFE tapes are used in heat sealing and pressing applications due to their high-temperature resistance. UHMW tapes are used for their abrasion resistance in textile machinery components.

These tapes are chosen for their specific properties that meet the demands of each industry, enhancing performance and longevity of applications.