Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

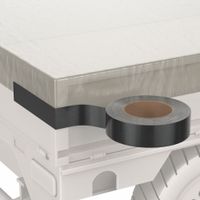

- Adhesives Sealants And Tape

- Tape

- Surface Protection Tape

.....Read More

Frequently Asked Questions

What is the best tape for surface protection?

The best tape for surface protection depends on the specific application and surface type. However, a few tapes are commonly recognized for their versatility and effectiveness:

1. **Painter's Tape**: Ideal for protecting surfaces during painting projects. It adheres well to walls, trim, and glass without leaving residue. It comes in various adhesion levels for different surfaces.

2. **Masking Tape**: Similar to painter's tape but generally has stronger adhesion. It's suitable for short-term protection on non-delicate surfaces.

3. **Polyethylene Tape**: Known for its durability and resistance to moisture and chemicals, making it suitable for protecting surfaces in industrial settings.

4. **Carpet Protection Film**: A self-adhesive film designed to protect carpets from dirt and spills during construction or moving.

5. **Surface Protection Film**: A clear, adhesive film used to protect surfaces like countertops, appliances, and floors from scratches and dirt.

6. **Gaffer's Tape**: Offers strong adhesion and is easy to remove without residue, making it ideal for temporary protection on various surfaces.

7. **Vinyl Tape**: Provides good abrasion resistance and is often used for marking and protecting surfaces in industrial environments.

8. **Duct Tape**: Known for its strong adhesion and versatility, though it can leave residue and is not recommended for delicate surfaces.

When choosing a tape, consider factors such as the surface material, duration of protection needed, environmental conditions, and ease of removal. Always test a small area first to ensure compatibility and avoid damage.

How do you apply surface protection film tape?

To apply surface protection film tape, follow these steps:

1. **Surface Preparation**: Ensure the surface is clean, dry, and free from dust, oil, or any contaminants. Use a mild detergent or cleaning solution if necessary, and allow the surface to dry completely.

2. **Measure and Cut**: Measure the area you need to cover and cut the film tape to the required size, leaving a slight excess for adjustments. Use a sharp utility knife or scissors for clean edges.

3. **Positioning**: Align the film tape with the surface, starting from one edge. Ensure it is straight and properly positioned before application.

4. **Application**: Begin applying the film tape from one end, gradually peeling off the backing as you go. Use a squeegee or a soft cloth to press the film onto the surface, working from the center outwards to remove air bubbles and ensure a smooth application.

5. **Smoothing**: Continuously smooth out the film with the squeegee or cloth to ensure full adhesion and to eliminate any remaining air pockets. Pay special attention to edges and corners.

6. **Trimming**: Once applied, trim any excess film using a utility knife for a neat finish. Be careful not to damage the underlying surface.

7. **Final Check**: Inspect the application for any bubbles or misalignments. If necessary, gently lift the film and reapply, smoothing it out again.

8. **Curing**: Allow the film to set and adhere properly, which may take a few hours depending on the manufacturer's instructions.

By following these steps, you can effectively apply surface protection film tape to safeguard surfaces from scratches, dirt, and damage.

Can surface protection tape be used on all surfaces?

Surface protection tape is designed to shield surfaces from damage, dust, and debris during manufacturing, transportation, or installation processes. However, it is not universally suitable for all surfaces. The effectiveness and suitability of surface protection tape depend on several factors:

1. **Surface Material**: Different tapes are formulated for specific materials such as glass, metal, plastic, or painted surfaces. Using the wrong type can lead to inadequate adhesion or damage upon removal.

2. **Surface Texture**: Smooth surfaces generally allow for better adhesion compared to rough or textured surfaces. Tapes may not adhere well to uneven surfaces, leading to potential lifting or inadequate protection.

3. **Adhesive Strength**: The adhesive strength of the tape must match the surface's tolerance. High-strength adhesives can damage delicate surfaces, while low-strength adhesives may not adhere well to robust surfaces.

4. **Environmental Conditions**: Factors like temperature, humidity, and exposure to sunlight can affect the tape's performance. Some tapes are designed to withstand extreme conditions, while others may degrade or lose adhesion.

5. **Duration of Application**: Long-term application can lead to adhesive residue or surface damage, especially if the tape is not designed for extended use.

6. **Chemical Compatibility**: Certain surfaces may react with the tape's adhesive, leading to discoloration or damage. It's crucial to ensure chemical compatibility before application.

7. **Removal Process**: Some surfaces may be sensitive to the removal process, which can cause peeling or damage if the tape is not designed for easy removal.

In conclusion, while surface protection tape is versatile, it is not universally applicable to all surfaces. It is essential to select the appropriate tape based on the specific surface characteristics and conditions to ensure effective protection without causing damage.

What are the benefits of using slick surface tape?

Slick surface tape offers several benefits across various applications:

1. **Reduced Friction**: Slick surface tape is designed to minimize friction, making it ideal for applications where smooth movement is essential. This can enhance the efficiency of machinery and reduce wear and tear on moving parts.

2. **Enhanced Durability**: The tape is often made from materials like PTFE (Teflon), which are resistant to chemicals, heat, and abrasion. This durability ensures a longer lifespan even in harsh environments.

3. **Improved Efficiency**: By reducing friction, slick surface tape can lead to improved operational efficiency. This is particularly beneficial in manufacturing processes where speed and precision are critical.

4. **Noise Reduction**: The smooth surface of the tape can help in reducing noise generated by moving parts, contributing to a quieter working environment.

5. **Versatility**: Slick surface tape can be used in a wide range of applications, from industrial machinery to household items. Its ability to adhere to various surfaces makes it a versatile tool for different industries.

6. **Easy Application**: The tape is typically easy to apply and remove, allowing for quick maintenance and replacement without significant downtime.

7. **Cost-Effective**: By extending the life of equipment and reducing maintenance needs, slick surface tape can be a cost-effective solution for businesses looking to optimize their operations.

8. **Temperature Resistance**: Many slick surface tapes can withstand extreme temperatures, making them suitable for use in environments with significant temperature fluctuations.

9. **Chemical Resistance**: The tape's resistance to various chemicals makes it suitable for use in chemical processing and other industries where exposure to corrosive substances is common.

10. **Non-Stick Properties**: The non-stick nature of slick surface tape prevents the build-up of materials, which is beneficial in applications like conveyor belts and packaging lines.

How long can preservation sealing tape be left on surfaces?

Preservation sealing tape, often used in construction, renovation, and shipping, is designed to protect surfaces from damage, dust, moisture, and other environmental factors. The duration for which it can be left on surfaces without causing damage or leaving residue depends on several factors, including the type of tape, the surface material, environmental conditions, and the manufacturer's specifications.

Typically, high-quality preservation sealing tapes are designed to be left on surfaces for a period ranging from a few days to several months. For instance, some tapes are formulated to remain effective and residue-free for up to 60 days, while others may be suitable for longer durations, such as 6 months or more. It is crucial to consult the manufacturer's guidelines for specific recommendations regarding the maximum duration the tape can be left on a particular surface.

The surface material also plays a significant role. Non-porous surfaces like glass, metal, and certain plastics are generally more forgiving and less likely to suffer damage or residue from prolonged tape application. In contrast, porous or delicate surfaces, such as painted walls or unfinished wood, may be more susceptible to damage or residue, necessitating shorter application periods.

Environmental conditions, such as temperature, humidity, and exposure to sunlight, can also impact the tape's performance. Extreme temperatures or prolonged exposure to UV light can degrade the adhesive, potentially leading to residue or difficulty in removal.

To ensure optimal results, it is advisable to test the tape on a small, inconspicuous area before full application and to adhere to the manufacturer's instructions regarding application and removal. Regular inspection of the tape and surface can help identify any potential issues early, allowing for timely removal or replacement if necessary.

Is mirror backing tape effective in preventing glass shattering?

Mirror backing tape can be effective in reducing the risk of glass shattering, but its effectiveness depends on several factors. This specialized tape is designed to reinforce mirrors and glass surfaces, providing an additional layer of protection. It works by holding the glass fragments together if the mirror is broken, thereby minimizing the risk of injury from sharp shards.

The effectiveness of mirror backing tape is influenced by the quality of the tape, the type of adhesive used, and the manner in which it is applied. High-quality tapes with strong adhesives are more likely to provide better protection. Proper application is crucial; the tape must be applied evenly and securely to ensure it adheres well to the glass surface.

Mirror backing tape is particularly useful in environments where safety is a concern, such as in homes with children, public spaces, or areas prone to impact. It is also beneficial in transportation, where vibrations and movements can increase the risk of breakage.

However, while mirror backing tape can help prevent shattering, it is not a foolproof solution. It may not withstand severe impacts or prevent breakage entirely. For comprehensive protection, it is often used in conjunction with other safety measures, such as tempered glass or safety films, which are designed to enhance the strength and durability of glass surfaces.

In summary, mirror backing tape is an effective tool for reducing the risk of glass shattering and enhancing safety, but its success depends on the quality of the tape, proper application, and the specific conditions in which it is used.

What are the common applications of impact protection tape?

Impact protection tape is commonly used in various applications to prevent damage and enhance safety. Here are some of its common applications:

1. **Automotive Industry**: Used to protect vehicle surfaces from scratches, chips, and dents caused by road debris, door dings, and minor collisions. It is often applied to bumpers, door edges, and side mirrors.

2. **Electronics**: Protects delicate components and surfaces of electronic devices during manufacturing, shipping, and handling. It helps prevent scratches and impacts that could damage screens and casings.

3. **Construction**: Applied to surfaces and edges of construction materials to prevent damage during transportation and installation. It is also used to protect finished surfaces from scratches and impacts during construction activities.

4. **Aerospace**: Used to protect aircraft surfaces from environmental damage and impacts during maintenance and operation. It helps maintain the integrity of the aircraft's exterior and reduces maintenance costs.

5. **Sports Equipment**: Applied to sports gear such as helmets, bicycles, and skateboards to protect against impacts and extend the lifespan of the equipment.

6. **Furniture and Appliances**: Protects surfaces from scratches and dents during moving and installation. It is often used on edges and corners to prevent damage during handling.

7. **Marine Industry**: Used on boats and marine equipment to protect against impacts and abrasions from water, docks, and other vessels.

8. **Industrial Machinery**: Protects machinery surfaces and components from impacts and abrasions during operation and maintenance, reducing wear and tear.

9. **Packaging**: Used in packaging to protect products from damage during shipping and handling, ensuring they reach their destination in good condition.

10. **Medical Equipment**: Protects sensitive medical devices and equipment from impacts and scratches during use and transportation.