Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

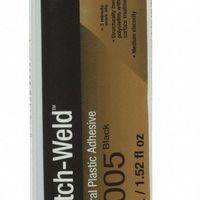

- Adhesives Sealants And Tape

- Adhesives Glues

- Load Bearing Structural Adhesives

.....Read More

Frequently Asked Questions

What are load-bearing structural adhesives?

Load-bearing structural adhesives are specialized bonding agents designed to support significant loads and stresses in structural applications. These adhesives are engineered to provide high strength, durability, and resistance to environmental factors, making them suitable for critical applications in industries such as aerospace, automotive, construction, and marine.

These adhesives work by forming a strong bond between surfaces, distributing loads across the bonded area, and maintaining structural integrity under various conditions. They are typically used in applications where mechanical fasteners like bolts or welds might be impractical or where a seamless finish is desired.

Key characteristics of load-bearing structural adhesives include:

1. **High Strength**: They offer exceptional tensile, shear, and peel strength, ensuring that the bonded materials can withstand significant forces without failure.

2. **Durability**: These adhesives are resistant to environmental factors such as temperature fluctuations, moisture, chemicals, and UV exposure, ensuring long-term performance.

3. **Versatility**: They can bond a wide range of materials, including metals, composites, plastics, and ceramics, making them suitable for diverse applications.

4. **Weight Reduction**: By eliminating the need for mechanical fasteners, these adhesives contribute to weight reduction, which is crucial in industries like aerospace and automotive for improving fuel efficiency.

5. **Stress Distribution**: They help in evenly distributing stress across the bonded surfaces, reducing the risk of stress concentrations that could lead to material failure.

Common types of load-bearing structural adhesives include epoxy, polyurethane, acrylic, and cyanoacrylate adhesives. Each type has specific properties tailored to different applications and material combinations.

In summary, load-bearing structural adhesives are critical components in modern engineering, providing reliable and efficient bonding solutions that enhance the performance and longevity of structural assemblies.

How do structural adhesives compare to mechanical fasteners?

Structural adhesives offer several advantages over mechanical fasteners. They distribute stress evenly across bonded surfaces, reducing localized stress concentrations that can lead to material fatigue. This results in improved durability and longevity of the joint. Adhesives also allow for the joining of dissimilar materials, such as metals to plastics, without causing galvanic corrosion, which is a risk with metal fasteners.

In terms of weight, adhesives are generally lighter than mechanical fasteners, contributing to overall weight reduction in applications like automotive and aerospace industries. This can lead to improved fuel efficiency and performance. Adhesives also provide a cleaner aesthetic, as they do not require holes or protrusions, maintaining the integrity and appearance of the surface.

However, mechanical fasteners have their own set of advantages. They provide immediate load-bearing capacity, whereas adhesives may require curing time. Fasteners are also easier to inspect and replace, offering straightforward disassembly and reassembly, which is beneficial for maintenance and repair. In high-temperature or chemically aggressive environments, mechanical fasteners may offer more reliable performance compared to some adhesives that can degrade under such conditions.

Ultimately, the choice between structural adhesives and mechanical fasteners depends on the specific requirements of the application, including load conditions, environmental factors, material compatibility, and design considerations.

What materials can structural adhesives bond?

Structural adhesives are versatile bonding agents capable of joining a wide range of materials. They are commonly used to bond metals, including aluminum, steel, and titanium, providing strong and durable joints. These adhesives are also effective with composites, such as carbon fiber and fiberglass, which are often used in aerospace and automotive industries for their strength-to-weight ratio.

Plastics, including ABS, PVC, and polycarbonate, can be bonded using structural adhesives, although surface preparation may be necessary to ensure optimal adhesion. Wood is another material that can be effectively bonded, making these adhesives suitable for applications in furniture and construction.

Ceramics and glass can also be bonded with structural adhesives, though special formulations may be required to accommodate their brittle nature and thermal expansion properties. Additionally, structural adhesives can bond dissimilar materials, such as metal to plastic or metal to composite, which is particularly useful in applications requiring lightweight and high-strength assemblies.

The choice of adhesive depends on factors such as the materials involved, the required strength, environmental conditions, and the specific application. Common types of structural adhesives include epoxies, acrylics, polyurethanes, and cyanoacrylates, each offering unique properties suited to different bonding needs.

What are the different types of structural adhesives?

Structural adhesives are used to bond components in load-bearing applications. The main types include:

1. **Epoxy Adhesives**: Known for their high strength and durability, epoxies are versatile and can bond a wide range of materials, including metals, composites, and plastics. They offer excellent chemical and environmental resistance.

2. **Acrylic Adhesives**: These adhesives provide fast curing times and strong bonds, even on oily or unprepared surfaces. They are often used in automotive and industrial applications due to their toughness and impact resistance.

3. **Polyurethane Adhesives**: Offering flexibility and good impact resistance, polyurethane adhesives are ideal for bonding dissimilar materials. They are commonly used in the construction and automotive industries.

4. **Cyanoacrylate Adhesives**: Also known as super glues, these adhesives cure rapidly and are suitable for small, precise applications. They work well on plastics, rubber, and metals but have limited gap-filling capabilities.

5. **Anaerobic Adhesives**: These adhesives cure in the absence of air and are typically used for locking and sealing threaded fasteners. They are ideal for metal-to-metal bonding.

6. **Silicone Adhesives**: Known for their flexibility and resistance to extreme temperatures, silicone adhesives are used in applications requiring thermal stability and weather resistance.

7. **Phenolic Adhesives**: These are used in high-temperature applications and provide excellent thermal and chemical resistance. They are often used in the aerospace and automotive industries.

8. **Urethane Methacrylate Adhesives**: Combining the properties of urethanes and acrylics, these adhesives offer fast curing and high strength, suitable for bonding metals and composites.

Each type of structural adhesive has unique properties that make it suitable for specific applications, depending on factors like material compatibility, environmental conditions, and mechanical requirements.

How strong are epoxy adhesives compared to other types?

Epoxy adhesives are among the strongest and most versatile adhesives available, often outperforming other types in terms of strength and durability. They are composed of a resin and a hardener that, when mixed, create a chemical reaction resulting in a rigid, high-strength bond. This makes them ideal for applications requiring robust adhesion and resistance to environmental factors.

Compared to other adhesives, such as cyanoacrylates (super glues), polyurethanes, and silicones, epoxies generally offer superior shear and tensile strength. They can bond a wide range of materials, including metals, plastics, ceramics, and wood, making them suitable for industrial, automotive, and aerospace applications. Epoxies also exhibit excellent resistance to chemicals, heat, and moisture, which enhances their performance in harsh conditions.

While cyanoacrylates provide quick bonding and are effective for small, non-porous surfaces, they lack the gap-filling properties and long-term durability of epoxies. Polyurethanes offer flexibility and impact resistance but may not match the high-temperature resistance of epoxies. Silicones are excellent for sealing and flexibility but generally do not provide the same level of structural strength.

Epoxies can be tailored for specific applications, with formulations that vary in curing time, viscosity, and temperature resistance. This customization allows for precise matching to the requirements of a particular project, further enhancing their effectiveness.

In summary, epoxy adhesives are exceptionally strong and versatile, often surpassing other adhesive types in strength, durability, and environmental resistance, making them a preferred choice for demanding applications.

What are the advantages of using acrylic adhesives?

Acrylic adhesives offer several advantages, making them a popular choice in various applications. Firstly, they provide excellent adhesion to a wide range of substrates, including metals, plastics, glass, and ceramics, ensuring strong and durable bonds. This versatility makes them suitable for diverse industries such as automotive, construction, electronics, and medical devices.

Secondly, acrylic adhesives exhibit superior resistance to environmental factors. They maintain their bonding strength under exposure to UV light, moisture, and temperature fluctuations, which is crucial for outdoor and high-performance applications. Their chemical resistance also ensures durability in harsh environments, including exposure to solvents and oils.

Another advantage is their fast curing time. Acrylic adhesives can achieve full strength quickly, which enhances production efficiency and reduces assembly time. This rapid curing is beneficial in high-speed manufacturing processes where time is a critical factor.

Acrylic adhesives also offer flexibility in formulation. They can be tailored to meet specific requirements, such as varying levels of viscosity, curing speed, and mechanical properties. This customization allows for precise application in specialized tasks.

Additionally, they provide excellent impact and peel strength, which is essential for applications requiring high mechanical performance. Their ability to absorb stress and distribute loads evenly across the bonded surfaces contributes to the longevity and reliability of the bond.

Finally, acrylic adhesives are often easy to apply, available in various forms such as liquids, pastes, and tapes, which simplifies the application process and reduces the need for specialized equipment.

In summary, the advantages of acrylic adhesives include strong adhesion to diverse materials, environmental resistance, fast curing, formulation flexibility, excellent mechanical properties, and ease of application, making them a versatile and reliable choice for many bonding needs.

When should urethane adhesives be used?

Urethane adhesives should be used when a strong, flexible bond is required, particularly in applications involving dissimilar materials. They are ideal for situations where resistance to environmental factors such as moisture, chemicals, and temperature fluctuations is necessary. Urethane adhesives are commonly used in the automotive industry for bonding parts that experience vibration and thermal expansion, such as windshields and body panels. They are also suitable for construction applications, including flooring and paneling, due to their ability to adhere to a variety of substrates like wood, metal, and concrete.

In the electronics industry, urethane adhesives are used for potting and encapsulating components, providing protection against dust, moisture, and mechanical stress. Their flexibility makes them suitable for applications where movement or expansion is expected, such as in the assembly of flexible circuits or wearable devices.

Urethane adhesives are also favored in the marine industry for their excellent water resistance, making them ideal for sealing and bonding in boat construction and repair. Additionally, they are used in the production of sporting goods, such as skis and snowboards, where durability and impact resistance are crucial.

When selecting urethane adhesives, consider the specific requirements of the application, such as cure time, viscosity, and the need for any additional properties like UV resistance or electrical insulation. Urethane adhesives are available in one-part and two-part formulations, with two-part systems offering faster curing times and greater control over the curing process.

Overall, urethane adhesives are versatile and effective for applications requiring a durable, resilient bond that can withstand environmental challenges and mechanical stress.