Call +(254) 703 030 000 / 751 483 999 / 721 704 777

.....Read More

Frequently Asked Questions

What is the difference between buffing and polishing?

Buffing and polishing are both processes used to enhance the appearance of surfaces, but they differ in their aggressiveness and the desired outcome. Polishing is typically the initial step, employing abrasive compounds to remove minor imperfections like scratches, oxidation, and swirl marks. This process levels the surface, creating a smoother finish. Buffing, on the other hand, is a less aggressive process that follows polishing. It uses finer compounds and softer pads to refine the surface, deepen the shine, and achieve a mirror-like gloss. Essentially, polishing corrects the surface, while buffing enhances its luster and clarity.

How do you choose the right buffing wheel for a project?

Choosing the right buffing wheel is crucial for achieving optimal results in polishing and finishing projects. Several factors influence this decision, including the material being buffed, the desired finish, and the type of compound being used.

Buffing wheels are typically made from various materials, such as cotton, felt, sisal, and flannel, each offering different levels of aggressiveness and softness. Sisal wheels, for instance, are very aggressive and are excellent for initial cutting and removing scratches on hard metals. Cotton wheels, on the other hand, are more versatile and come in different weaves (e.g., spiral sewn, loose leaf) for various stages of polishing, from cutting to coloring. Felt wheels are ideal for precision polishing and achieving a high-gloss finish, especially with softer materials. Flannel wheels are the softest and are used for final delicate polishing or for applying protective coatings.

The type of buffing compound also plays a significant role. Coarser compounds require more aggressive wheels for effective cutting, while finer compounds pair best with softer wheels for a brilliant shine. It's often a multi-step process, starting with a more aggressive wheel and compound to remove imperfections, then progressing to finer combinations for a mirror-like finish. Always consider the material's hardness – a softer material will require a less aggressive wheel to prevent damage.

What types of buffing compounds are available and how are they used?

Buffing compounds are abrasive materials used to polish and finish surfaces, typically with a buffing wheel. They come in various types, each designed for specific materials and desired finishes.

Common types include: * "Cut" compounds: These are more aggressive, with larger abrasive particles, used for removing scratches, heavy oxidation, and surface imperfections. They are often dark-colored (e.g., black, brown) and used for initial stages of polishing.

* "Color" or "Finish" compounds: These have finer abrasives and are used for creating a high shine, removing haziness left by cutting compounds, and achieving a mirror-like finish. They are typically lighter in color (e.g., white, green, blue).

* Jeweler's Rouge: A very fine abrasive, often red or green, used for final polishing of precious metals and delicate items to achieve an extremely high luster.Usage involves applying a small amount of the compound to a spinning buffing wheel and then pressing the workpiece against the wheel. The choice of compound depends on the material being buffed (metal, plastic, wood) and the desired outcome, ranging from aggressive material removal to a delicate, high-gloss polish. Safety precautions, such as wearing eye protection and gloves, are important when working with buffing compounds and machinery.

How do you attach a buffing wheel to a bench grinder?

To attach a buffing wheel to a bench grinder, you typically need the appropriate arbor adapters, sometimes called buffing wheel adapters or mandrels. These adapters have a threaded shaft on one end that screws onto the grinder's arbor (the shaft extending from the motor) and a flat flange with a nut on the other end to secure the buffing wheel.

Here's a general procedure:1. **Safety First:** Unplug the bench grinder before starting any work on it.

2. **Remove Existing Wheels (if any):** If there are grinding wheels on the arbor, carefully remove the retaining nuts and flanges.

3. **Clean the Arbor:** Ensure the grinder's arbor is clean and free of debris.

4. **Install the Adapter:** Screw the buffing wheel adapter onto the grinder's arbor. Make sure it's threaded all the way on and tight. Some adapters might have a set screw to further secure them.

5. **Mount the Buffing Wheel:** Slide the buffing wheel onto the adapter's shaft. The wheel should fit snugly.

6. **Secure the Wheel:** Place the outer flange and then the retaining nut onto the adapter's shaft. Tighten the nut firmly, but do not overtighten, as this can damage the wheel or adapter.

7. **Check for Wobble:** Spin the wheel by hand to ensure it runs true and doesn't wobble. If it wobbles, re-adjust and re-tighten.

8. **Test Run:** Plug in the grinder and briefly turn it on to ensure the wheel is securely attached and balanced. If there's excessive vibration, turn it off and re-check the installation.Always refer to the manufacturer's instructions for both your specific bench grinder and the buffing wheel/adapter, as there can be variations in design and installation requirements. Ensure the buffing wheel's maximum RPM rating is suitable for your grinder's speed.

What safety precautions should be taken when buffing and polishing?

When buffing and polishing, it's crucial to prioritize safety to prevent injuries and ensure a quality finish. Always wear appropriate personal protective equipment (PPE), including safety glasses or a face shield to protect against flying debris and splashes, and gloves to shield hands from chemicals and friction. A dust mask or respirator is essential to prevent inhalation of fine particles generated during the process.

Ensure proper ventilation in your workspace to dissipate fumes from polishes and compounds, which can be irritating or harmful if inhaled. If working indoors, consider using fans or an exhaust system.

Secure the workpiece firmly to prevent it from slipping or being thrown during operation. Use clamps, a vise, or specialized polishing jigs. Never hold small pieces by hand directly against a fast-spinning wheel.

Be aware of the rotational direction of the buffing wheel and the material flow. Work against the direction of rotation when polishing, which helps prevent the workpiece from being snagged and thrown. Maintain a firm, controlled grip on the workpiece.

Use the correct buffing wheel and compound for the material and desired finish. Over-aggressive buffing or using the wrong abrasive can cause overheating, damage the material, or create hazardous conditions. Avoid excessive pressure, as this can lead to heat buildup, material distortion, or even fire in some cases.

Regularly inspect your equipment, including the buffing machine, wheels, and cords, for any damage or wear. Replace worn or damaged components immediately. Keep your work area clean and free of clutter to prevent trips and falls. Flammable materials should be stored away from the buffing area due to the potential for sparks or heat generation. In case of an emergency, know the location of fire extinguishers and first-aid kits.

How do you maintain and clean buffing wheels?

Maintaining and cleaning buffing wheels is crucial for optimal performance and longevity. After each use, remove excess compound by gently tapping the wheel or using a stiff brush. For a deeper clean, consider using a buffing wheel rake or dresser to remove hardened compound and re-fluff the fibers. For heavily soiled wheels, a mild degreaser or specialized buffing wheel cleaner can be applied, followed by rinsing with warm water. Ensure the wheel is thoroughly dry before storing to prevent mildew and degradation. Regular maintenance ensures efficient buffing and a consistent finish.

What are the best techniques for buffing metal surfaces?

Buffing metal surfaces involves several techniques to achieve a smooth and shiny finish. First, ensure the metal is clean and free of debris. Start with a coarse abrasive compound and a sisal or spiral-sewn buffing wheel to remove scratches and imperfections. Apply light to medium pressure, keeping the wheel moving to avoid heat buildup. Progress to finer compounds like Tripoli or white rouge with cotton buffing wheels to refine the surface. For a mirror finish, use a very fine compound such as jeweler's rouge with a soft flannel or Canton flannel wheel, applying minimal pressure. Always buff in multiple directions and frequently clean the buffing wheel to prevent transferring contaminants.

Can buffing and polishing be used on plastic and composite materials?

Yes, buffing and polishing can be used on plastic and composite materials, but it requires different techniques and products than those used for metals or other hard surfaces. Plastics and composites are generally softer and more susceptible to heat, so aggressive buffing can easily cause damage like melting, distortion, or haze.

For plastics, a multi-stage approach is usually best. Start with finer abrasives if there are scratches, then progressively move to less aggressive compounds and softer buffing pads. Polishing compounds specifically designed for plastic are crucial, as they contain finer abrasives that won't scratch the surface. Low speeds and light pressure are essential to avoid generating excessive heat.

Composite materials, depending on their matrix (e.g., resin, carbon fiber), can also be buffed and polished. The key is to use very fine polishes and soft pads to avoid damaging the composite's structural integrity or finish. Some composites may even have a clear coat that can be polished like automotive paint. Always test on an inconspicuous area first to ensure compatibility and desired results.

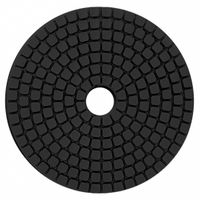

How do diamond polishing pads work on stone surfaces?

Diamond polishing pads utilize industrial diamonds, the hardest known material, to abrade and smooth stone surfaces. These pads consist of diamond particles embedded in a resin or metal matrix, typically attached to a flexible backing. When used with a polisher, the pads spin at high speeds, and the diamond particles act as microscopic cutting tools.

The polishing process usually involves a series of pads with progressively finer grit sizes. Coarse grit pads (e.g., 50 or 100 grit) are used first to remove significant imperfections, scratches, and to level the surface. These coarser diamonds aggressively cut into the stone, creating a uniform matte finish.

As you move to finer grit pads (e.g., 400, 800, 1500, 3000 grit), the diamond particles become smaller and less abrasive. These finer grits refine the surface, gradually reducing the microscopic scratches created by the previous, coarser pads. This progressive removal of scratches leads to an increasingly smooth and reflective surface.

The friction generated during polishing, especially with finer grits, also contributes to the shine by compacting the stone's surface and bringing out its natural luster. Water is often used during the process as a lubricant to reduce heat, prevent dust, and carry away abraded material, resulting in a cleaner and more effective polish. The final result is a highly polished, reflective stone surface.

What is the role of lapping compounds in achieving high tolerances?

Lapping compounds are abrasive mixtures used to achieve extremely precise surface finishes and tight dimensional tolerances on various materials. They consist of abrasive particles, such as diamond, silicon carbide, or aluminum oxide, suspended in a liquid or paste medium.

The primary role of lapping compounds in achieving high tolerances lies in their ability to perform controlled material removal at a microscopic level. During the lapping process, the compound is introduced between two surfaces (the workpiece and a lapping plate or another workpiece). The abrasive particles, suspended in the medium, roll and slide between these surfaces, gradually removing minute amounts of material from the high spots. This action progressively refines the surface, reducing irregularities and creating a flatter, smoother, and more uniform finish.

The fine abrasive particles and the controlled nature of the lapping process allow for the removal of material in increments as small as micrometers or even nanometers. This precision is crucial for achieving high tolerances, which are critical in applications where components need to fit together with extreme accuracy or exhibit specific surface properties. Examples include optical lenses, sealing surfaces, precision bearings, and gauge blocks, where even microscopic imperfections can significantly impact performance. The choice of lapping compound (abrasive type, particle size, and concentration) is tailored to the specific material, desired finish, and tolerance requirements.