Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

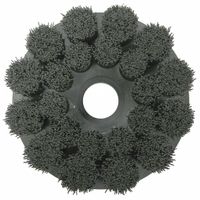

- Abrasives

- Abrasive Brushes

- Disc Brushes

.....Read More

Frequently Asked Questions

What are disc brushes used for?

Disc brushes are versatile tools used in various industries for surface finishing, cleaning, deburring, and polishing applications. They consist of a circular base with bristles or filaments extending outward, which can be made from materials like nylon, wire, or abrasive-filled nylon, depending on the application requirements.

In manufacturing and metalworking, disc brushes are commonly used for deburring, which involves removing sharp edges or burrs from metal parts after machining processes. This ensures that components are safe to handle and fit together properly in assemblies. The flexibility of the bristles allows the brush to conform to the contours of the workpiece, providing consistent and uniform results.

In the automotive and aerospace industries, disc brushes are employed for surface preparation tasks, such as cleaning and polishing metal surfaces before painting or coating. This helps improve adhesion and ensures a high-quality finish. They are also used for removing rust, scale, and other surface contaminants from metal parts.

In woodworking, disc brushes are used for sanding and finishing wood surfaces. They can smooth out rough edges and prepare the wood for staining or painting, enhancing the overall appearance and quality of the finished product.

In electronics and semiconductor manufacturing, disc brushes are used for cleaning delicate components and circuit boards. The soft bristles can remove dust and debris without damaging sensitive parts.

Overall, disc brushes are essential tools in various industries due to their ability to efficiently and effectively perform a wide range of surface treatment tasks, improving product quality and extending the lifespan of components.

How do disc brushes remove rust and paint?

Disc brushes remove rust and paint through a combination of mechanical abrasion and friction. These brushes are typically made with bristles composed of abrasive materials such as steel wire, nylon impregnated with abrasive grains, or other durable materials. When the disc brush is attached to a power tool, such as a grinder or drill, it rotates at high speeds.

As the brush spins, the abrasive bristles come into contact with the surface of the metal or painted object. The high-speed rotation allows the bristles to scrape away the top layers of rust or paint. The abrasive action is effective because it physically breaks down the bonds between the rust or paint and the underlying metal surface. The friction generated by the rotating bristles also helps to heat and loosen the material, making it easier to remove.

The effectiveness of a disc brush in removing rust and paint depends on several factors, including the type of abrasive material used in the bristles, the speed of rotation, the pressure applied, and the condition of the surface being treated. Coarser bristles are generally more effective for heavy rust or thick layers of paint, while finer bristles are suitable for lighter applications or finishing work.

Disc brushes are favored for their ability to conform to irregular surfaces and reach into crevices, providing a more uniform finish compared to other methods. They are also less likely to damage the underlying metal compared to more aggressive techniques like sandblasting. However, care must be taken to select the appropriate brush and technique to avoid excessive wear on the metal surface.

What materials are disc brushes made from?

Disc brushes are made from a variety of materials, each chosen for specific properties that suit different applications. The base or core of the disc brush is typically made from durable materials like plastic, wood, or metal, depending on the intended use and the environment in which the brush will operate.

The bristles of disc brushes are crafted from several materials, each offering unique characteristics:

1. **Nylon**: This is a common material for disc brush bristles due to its flexibility, durability, and resistance to wear and chemicals. Nylon bristles are suitable for general-purpose cleaning and polishing tasks.

2. **Polypropylene**: Known for its chemical resistance and low water absorption, polypropylene is used for applications where exposure to moisture or chemicals is a concern.

3. **Abrasive Nylon**: These bristles are impregnated with abrasive materials like silicon carbide or aluminum oxide, making them ideal for deburring, surface finishing, and edge blending.

4. **Wire**: Steel, stainless steel, or brass wires are used for heavy-duty applications requiring aggressive cleaning or material removal. Wire bristles are effective for rust removal, paint stripping, and surface preparation.

5. **Natural Fibers**: Materials like horsehair or tampico are used for delicate applications where gentle cleaning is required. These fibers are softer and less abrasive than synthetic options.

6. **Carbon Fiber**: Used in high-tech or specialized applications, carbon fiber bristles offer static dissipation and are lightweight yet strong.

The choice of material for disc brush bristles depends on factors such as the surface being worked on, the desired finish, and the environmental conditions. Each material offers distinct advantages, making disc brushes versatile tools in industrial, commercial, and domestic settings.

Can disc brushes be used on irregular surfaces?

Yes, disc brushes can be used on irregular surfaces. These brushes are designed with flexible bristles that can adapt to the contours and variations of uneven surfaces. The flexibility of the bristles allows them to reach into crevices and conform to the shape of the surface, ensuring effective cleaning or finishing. Disc brushes are often used in applications such as deburring, surface finishing, and cleaning where the surface may not be perfectly flat. Their design allows for consistent contact with the surface, which is crucial for achieving uniform results. Additionally, the rotational motion of disc brushes helps in covering a larger area efficiently, making them suitable for irregular surfaces.

How do CNC machine disc brushes work?

CNC machine disc brushes are specialized tools used for surface finishing, deburring, and edge radiusing in CNC machining processes. These brushes consist of a circular base embedded with abrasive filaments, which can be made from materials like nylon impregnated with abrasive grains such as silicon carbide, aluminum oxide, or diamond. The design and material of the filaments are chosen based on the specific application and the material of the workpiece.

The working principle of CNC machine disc brushes involves their rotation at high speeds, driven by the CNC machine's spindle. As the brush rotates, the abrasive filaments come into contact with the surface of the workpiece. The flexibility of the filaments allows them to conform to the contours of the workpiece, effectively removing burrs, smoothing rough edges, and providing a uniform surface finish without altering the part's critical dimensions.

The CNC machine's software controls the brush's speed, direction, and pressure applied to the workpiece, ensuring precision and consistency. The brush can be programmed to follow complex paths, making it suitable for intricate parts with complex geometries. The abrasive action of the filaments is gentle enough to avoid damaging the workpiece while being effective in removing unwanted material.

CNC machine disc brushes are used in various industries, including automotive, aerospace, and metalworking, where high-quality surface finishes and precise deburring are essential. They offer advantages such as reduced manual labor, improved consistency, and the ability to process multiple parts simultaneously, enhancing productivity and efficiency in manufacturing operations.

What are the benefits of using bristle brushes?

Bristle brushes offer several benefits across various applications, from painting to personal grooming. In painting, bristle brushes, typically made from natural hog hair, are valued for their durability and ability to hold a significant amount of paint. This allows for smoother application and the creation of textured effects, making them ideal for oil and acrylic painting. The stiffness of the bristles provides excellent control, enabling artists to achieve both broad strokes and fine details.

In personal grooming, bristle brushes, especially those made from boar bristles, are beneficial for hair care. They help distribute natural oils from the scalp throughout the hair, enhancing shine and reducing frizz. This natural oil distribution also promotes healthier hair by moisturizing and conditioning it. Bristle brushes can gently detangle hair without causing breakage, making them suitable for all hair types, including fine and curly hair.

For cleaning purposes, bristle brushes are effective due to their robust and flexible nature. They can reach into crevices and corners, making them ideal for scrubbing surfaces and removing stubborn dirt. In skincare, dry brushing with natural bristle brushes can exfoliate the skin, improve circulation, and promote lymphatic drainage, contributing to healthier skin.

Overall, bristle brushes are versatile tools that offer durability, effective application, and enhanced results in various fields, from art to personal care and cleaning.

Are disc brushes suitable for automated cleaning applications?

Yes, disc brushes are suitable for automated cleaning applications. They are designed to provide efficient and effective cleaning solutions across various industries. Disc brushes are particularly advantageous in automated systems due to their versatility, durability, and ability to conform to different surfaces.

1. **Versatility**: Disc brushes can be used on a wide range of surfaces, including metal, plastic, and wood. They are effective in removing debris, dust, and contaminants, making them ideal for diverse cleaning tasks in automated systems.

2. **Durability**: Made from robust materials such as nylon, polypropylene, or wire, disc brushes are built to withstand rigorous use. This durability ensures a long lifespan, reducing the need for frequent replacements and maintenance in automated cleaning setups.

3. **Conformability**: The design of disc brushes allows them to adapt to irregular surfaces and contours. This feature is crucial in automated cleaning applications where the brush must maintain consistent contact with the surface to ensure thorough cleaning.

4. **Efficiency**: Disc brushes can cover large areas quickly, making them suitable for high-speed automated cleaning processes. Their design allows for uniform distribution of pressure, ensuring even cleaning across the entire surface.

5. **Customization**: Disc brushes can be customized in terms of size, bristle material, and stiffness to meet specific cleaning requirements. This adaptability makes them suitable for a wide range of automated cleaning applications, from delicate tasks to heavy-duty cleaning.

6. **Integration**: Disc brushes can be easily integrated into automated systems, such as robotic arms or conveyor belts, enhancing the overall efficiency and effectiveness of the cleaning process.

In summary, disc brushes are well-suited for automated cleaning applications due to their versatility, durability, and ability to provide consistent and efficient cleaning across various surfaces and industries.