- Home

- Abrasives

- Abrasive Blasting

- Blasting Cabinet Parts Accessories

.....Read More

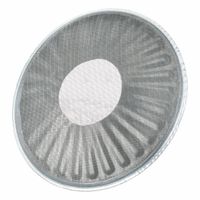

Compressed Air Treatment for Blasting Cabinets

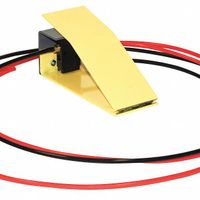

Foot Pedals & Controls for Blasting Cabinets

Gaskets for Blasting Cabinets

Gloves for Blasting Cabinets

Hoses & Hose Fittings for Blasting Cabinets

Lighting for Blasting Cabinets

Media Delivery Components for Blasting Cabinets

Window & Door Components for Blasting Cabinets

Work Area Components for Blasting Cabinets

Frequently Asked Questions

What are the essential parts of a blasting cabinet?

How do I replace the gloves on a blasting cabinet?

What type of nozzle should I use for my blasting cabinet?

How do I maintain the dust collector in a blasting cabinet?

What is the best way to repair a leaking blasting cabinet door?

How do I connect a new foot pedal to my blasting cabinet?

What accessories can improve the efficiency of my blasting cabinet?