Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Tools

- Sockets Bits

- Sockets Sets

- Impact Sockets Sets

.....Read More

Frequently Asked Questions

What are impact sockets used for?

Impact sockets are specialized tools designed for use with impact wrenches and drivers, which deliver high torque output to loosen or tighten fasteners. These sockets are constructed from high-strength materials, typically chrome molybdenum or chrome vanadium steel, to withstand the intense forces generated by impact tools. The primary purpose of impact sockets is to handle the high torque and vibrations without cracking or shattering, which can occur with regular sockets.

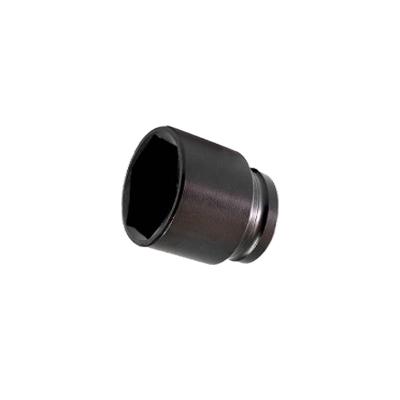

The key features of impact sockets include thicker walls and a black oxide or phosphate finish, which provides corrosion resistance and reduces wear. The thicker walls help absorb the shock and distribute the force evenly, preventing damage to both the socket and the fastener. The black finish also differentiates them from standard sockets, which are usually chrome-plated.

Impact sockets are commonly used in automotive repair, heavy machinery maintenance, and construction, where high torque applications are frequent. They are essential for tasks such as removing lug nuts, bolts, and other fasteners that are rusted, seized, or require significant force to manipulate. Their design ensures safety and efficiency, reducing the risk of tool failure and potential injury.

In summary, impact sockets are crucial for high-torque applications, providing durability, safety, and reliability in demanding environments.

How do impact sockets differ from regular sockets?

Impact sockets differ from regular sockets in several key ways:

1. **Material Composition**: Impact sockets are typically made from chrome molybdenum steel, which is more ductile and can absorb the sudden torque spikes from impact tools. Regular sockets are usually made from chrome vanadium steel, which is harder but more brittle.

2. **Design and Construction**: Impact sockets have thicker walls to withstand the high torque and vibrations from impact wrenches. This makes them more robust and less prone to cracking under stress. Regular sockets have thinner walls, designed for hand tools where the force applied is more controlled.

3. **Finish**: Impact sockets often have a black oxide or phosphate finish to prevent corrosion and reduce glare. Regular sockets usually have a polished chrome finish for ease of cleaning and aesthetic appeal.

4. **Safety Features**: Impact sockets are designed to handle the extreme forces of impact tools safely. They are less likely to shatter, reducing the risk of injury. Regular sockets can shatter if used with impact tools, posing a safety hazard.

5. **Drive End Design**: The drive end of impact sockets is often designed with a cross-hole and ring groove to secure them to the impact tool, preventing them from flying off during use. Regular sockets typically rely on friction or a detent ball for retention.

6. **Cost**: Due to their specialized materials and construction, impact sockets are generally more expensive than regular sockets.

7. **Application**: Impact sockets are specifically designed for use with impact wrenches and drivers, while regular sockets are intended for use with hand tools like ratchets and torque wrenches. Using the correct type of socket for the tool is crucial for both performance and safety.

Can impact sockets be used with a regular ratchet?

Yes, impact sockets can be used with a regular ratchet. Impact sockets are designed to withstand the high torque and vibrations produced by impact wrenches, making them more durable than regular sockets. They are typically made from chrome molybdenum steel, which is stronger and more resistant to wear and tear compared to the chrome vanadium steel used in standard sockets.

When using impact sockets with a regular ratchet, you benefit from their increased durability and reduced risk of cracking or breaking under stress. This can be particularly advantageous in heavy-duty applications or when working with stubborn fasteners. The thicker walls of impact sockets also provide added strength, although this can make them slightly bulkier and heavier than standard sockets.

However, there are a few considerations to keep in mind. The thicker walls of impact sockets may limit access in tight spaces where clearance is an issue. Additionally, while impact sockets are perfectly compatible with regular ratchets, they are not necessary for tasks that do not require the high torque levels of an impact wrench. In such cases, standard sockets are sufficient and may be more convenient due to their lighter weight and slimmer profile.

In summary, while impact sockets can be used with a regular ratchet without any issues, their use is most beneficial in situations where durability and strength are prioritized. For everyday tasks, standard sockets may be more practical, but having impact sockets on hand can be advantageous for more demanding applications.

What materials are impact sockets made from?

Impact sockets are typically made from materials that can withstand high torque and sudden impacts. The most common materials used are:

1. **Chrome Molybdenum Steel (Cr-Mo):** This is the most prevalent material for impact sockets. It is an alloy steel that combines chromium and molybdenum, offering excellent strength, toughness, and resistance to wear and impact. Cr-Mo steel is known for its ability to absorb shock without cracking or shattering, making it ideal for high-stress applications.

2. **Chrome Vanadium Steel (Cr-V):** While more commonly used for standard sockets, some impact sockets are also made from chrome vanadium steel. This material provides good strength and durability, though it is generally not as tough as chrome molybdenum. Cr-V sockets are often used for lighter-duty impact applications.

3. **Carbon Steel:** Some impact sockets are made from high-strength carbon steel. These are typically less expensive and may not offer the same level of durability as Cr-Mo or Cr-V sockets. They are suitable for less demanding applications where extreme impact resistance is not required.

4. **Alloy Steel:** Various other alloy steels may be used, combining different elements to achieve specific properties such as increased hardness, toughness, or resistance to wear and corrosion.

Impact sockets are often coated with a black oxide finish to prevent corrosion and reduce friction. This finish also helps in identifying them as impact-rated, distinguishing them from standard sockets. The choice of material and finish ensures that impact sockets can handle the rigorous demands of power tools like impact wrenches, providing reliability and safety in heavy-duty applications.

Are impact sockets necessary for impact wrenches?

Yes, impact sockets are necessary for impact wrenches. Impact sockets are specifically designed to withstand the high torque and vibrations produced by impact wrenches. They are made from thicker, more durable materials, typically chrome molybdenum, which can handle the stress without cracking or shattering. Regular sockets, often made from chrome vanadium, are not built to endure such forces and can break, posing safety risks.

Impact sockets also feature a black oxide or phosphate finish to prevent corrosion and reduce friction, which is not typically found on regular sockets. This finish helps in maintaining the integrity of the socket under extreme conditions. Additionally, impact sockets have a more robust design with thicker walls and a deeper broach, allowing them to grip fasteners more securely and reducing the likelihood of rounding off the corners of nuts and bolts.

Using regular sockets with an impact wrench can lead to socket failure, damage to the tool, and potential injury to the user. Therefore, for safety, efficiency, and longevity of both the tool and the sockets, it is essential to use impact sockets with impact wrenches.

How do you choose the right size impact socket set?

1. **Determine Usage Needs**: Identify the types of projects or tasks you will be using the impact socket set for, such as automotive repair, construction, or general maintenance.

2. **Drive Size**: Choose the drive size based on the tools you have. Common drive sizes are 1/4-inch, 3/8-inch, 1/2-inch, 3/4-inch, and 1-inch. Match the drive size to your impact wrench or ratchet.

3. **Socket Size Range**: Consider the range of socket sizes you need. A comprehensive set should include both metric and SAE sizes if you work with both types of fasteners. Ensure the set covers the most common sizes you encounter.

4. **Material and Durability**: Opt for sockets made from high-quality materials like chrome molybdenum or chrome vanadium for durability and strength. Look for sets with a black phosphate or black oxide finish to resist corrosion.

5. **Point Design**: Decide between 6-point and 12-point sockets. 6-point sockets provide a better grip and are less likely to round off fasteners, making them ideal for impact use.

6. **Depth**: Choose between shallow and deep sockets. Deep sockets are useful for reaching nuts on longer bolts, while shallow sockets are suitable for tight spaces.

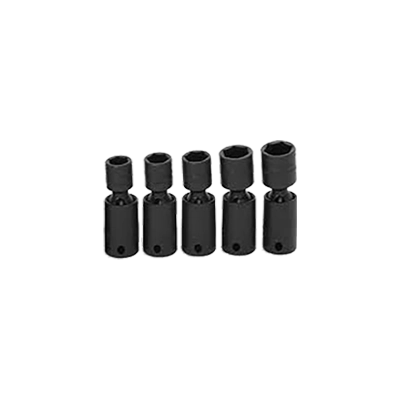

7. **Set Completeness**: Ensure the set includes extensions, universal joints, and adapters if needed for versatility.

8. **Brand and Warranty**: Consider reputable brands known for quality and durability. Check for a warranty or guarantee for added assurance.

9. **Budget**: Balance quality with affordability. Investing in a good set can save money in the long run by reducing the need for replacements.

10. **Storage**: Look for sets that come with a sturdy case or organizer for easy storage and transport.

What are the benefits of using impact sockets over standard sockets?

Impact sockets offer several benefits over standard sockets, particularly in high-torque applications. Firstly, impact sockets are made from tougher materials, such as chrome molybdenum, which can withstand the high torque and vibrations generated by impact tools. This durability reduces the risk of cracking or shattering under stress, enhancing safety and longevity.

Secondly, impact sockets have a thicker wall design compared to standard sockets. This increased thickness provides additional strength and resistance to deformation, making them ideal for heavy-duty tasks. The black oxide or phosphate coating on impact sockets also offers better corrosion resistance, extending their lifespan in harsh environments.

Another advantage is the design of the drive end. Impact sockets often feature a cross-hole design and a ring groove, allowing for secure attachment to impact wrenches and reducing the likelihood of the socket slipping off during use. This secure fit ensures efficient power transfer from the tool to the fastener, improving performance and reducing wear on both the tool and the socket.

Impact sockets are also designed to handle the repetitive, high-impact forces of power tools without rounding off fasteners. This precision helps maintain the integrity of the fasteners, preventing damage and ensuring a snug fit.

In summary, impact sockets provide enhanced durability, safety, and performance in demanding applications, making them a superior choice over standard sockets when using impact tools.