Call +(254) 703 030 000 / 751 483 999 / 721 704 777

- Home

- Tools

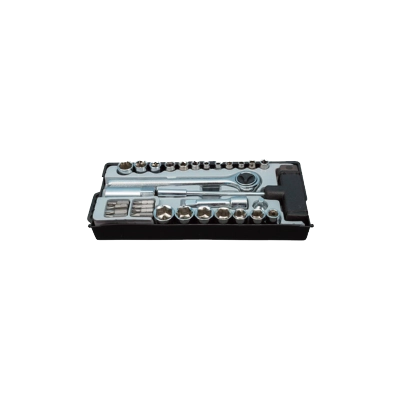

- Sockets Bits

- Sockets Sets

- Hand Socket Sets

.....Read More

Frequently Asked Questions

What are the different types of hand sockets and their uses?

Hand sockets, commonly used in conjunction with ratchets or wrenches, come in various types, each designed for specific applications:

1. **Standard Sockets**: These are the most common and are used for general-purpose applications. They come in both metric and SAE (Society of Automotive Engineers) sizes to fit different bolt and nut sizes.

2. **Deep Sockets**: These are longer than standard sockets and are used to reach nuts on long bolts or in recessed areas. They provide extra clearance for protruding bolt ends.

3. **Impact Sockets**: Made from thicker, more durable materials, these sockets are designed to withstand the high torque of impact wrenches. They are typically black due to a protective coating.

4. **Universal Joint Sockets**: These have a swivel joint that allows the socket to pivot, making it easier to reach fasteners at awkward angles.

5. **Spark Plug Sockets**: Specifically designed for removing and installing spark plugs, these sockets often have a rubber insert to protect the plug and ensure a secure grip.

6. **Hex Bit Sockets**: These combine a hex bit with a socket, allowing for the use of hex fasteners with a ratchet.

7. **Torx Bit Sockets**: Similar to hex bit sockets, these are used for Torx fasteners, which are star-shaped and provide better torque transfer.

8. **Flex Sockets**: These have a built-in flexible joint, allowing for access to fasteners in tight or angled spaces.

9. **Pass-Through Sockets**: These allow the bolt or stud to pass through the socket, useful for long bolts or threaded rods.

10. **Insulated Sockets**: Used for electrical work, these sockets are insulated to protect against electric shock.

Each type of socket is designed to address specific challenges in fastening, ensuring efficiency and safety in various mechanical and automotive tasks.

How do I choose the right socket size for a fastener?

1. **Identify the Fastener Type**: Determine if the fastener is metric or imperial. This will guide you in choosing between metric and SAE (Society of Automotive Engineers) socket sizes.

2. **Measure the Fastener**: Use a caliper or a ruler to measure the width across the flats of the bolt or nut. This measurement is the size of the socket you need.

3. **Check the Fastener Head**: Identify the shape of the fastener head. Common shapes include hexagonal, square, or Torx. Ensure the socket matches the shape.

4. **Select the Drive Size**: Choose the appropriate drive size for your socket wrench. Common drive sizes are 1/4-inch, 3/8-inch, 1/2-inch, and 3/4-inch. Match the drive size to the torque requirement and space constraints.

5. **Consider the Socket Type**: Decide between a standard socket and a deep socket. Use deep sockets for fasteners on long bolts or recessed areas.

6. **Test Fit**: Before applying force, test the socket on the fastener to ensure a snug fit. The socket should slide over the fastener easily but not wobble.

7. **Use a Socket Set**: If unsure, use a socket set that includes a range of sizes. This allows you to try different sockets until you find the perfect fit.

8. **Check for Wear and Damage**: Ensure the socket is in good condition without cracks or wear, which could lead to slipping or damage.

9. **Consult Manufacturer Specifications**: Refer to any available documentation or specifications for the fastener to confirm the correct socket size.

10. **Use Conversion Charts**: If necessary, use conversion charts to switch between metric and imperial sizes.

What is the difference between standard and deep sockets?

Standard sockets are shorter and are used for general applications where the bolt or nut is easily accessible. They provide sufficient torque for most tasks and are ideal for working in tight spaces where a longer socket might not fit. Standard sockets are typically used for shallow fasteners and are more compact, making them easier to handle and store.

Deep sockets, on the other hand, are longer and designed to reach nuts on longer bolts or threaded rods. They provide additional clearance and are useful for applications where the bolt extends beyond the nut, requiring more depth to fully engage the fastener. Deep sockets are essential for tasks involving recessed fasteners or when working with long studs. They offer greater versatility in accessing hard-to-reach areas and are often used in automotive and industrial settings.

In summary, the primary difference lies in their length and application: standard sockets are shorter and suited for general use, while deep sockets are longer and designed for reaching fasteners in deeper or recessed positions.

How do I maintain and care for my socket set?

To maintain and care for your socket set, follow these steps:

1. **Cleaning**: After each use, wipe down sockets and ratchets with a clean cloth to remove dirt, grease, and debris. For stubborn grime, use a mild detergent and water, then dry thoroughly to prevent rust.

2. **Lubrication**: Apply a light machine oil or lubricant to moving parts of ratchets to ensure smooth operation. Avoid over-lubricating, as excess oil can attract dirt.

3. **Rust Prevention**: Store your socket set in a dry environment. Use silica gel packs in the toolbox to absorb moisture. Consider applying a rust inhibitor spray for added protection.

4. **Storage**: Keep sockets organized in their designated case or on a socket rail to prevent loss and damage. Ensure the storage area is clean and free from moisture.

5. **Inspection**: Regularly inspect sockets and ratchets for wear, cracks, or damage. Replace any damaged tools to maintain safety and efficiency.

6. **Proper Use**: Use the correct size socket for the job to avoid stripping or damaging fasteners. Avoid using sockets with impact tools unless they are specifically designed for that purpose.

7. **Avoid Over-Torquing**: Be mindful of the torque applied to prevent damaging the sockets or fasteners. Use a torque wrench when precision is required.

8. **Handle with Care**: Avoid dropping sockets and ratchets, as this can cause damage or misalignment.

9. **Labeling**: Clearly label your socket set for easy identification and to ensure quick access during use.

10. **Regular Inventory**: Periodically check that all pieces are accounted for and in good condition, replacing any missing or damaged items promptly.

By following these steps, you can extend the life of your socket set and ensure it remains in optimal working condition.

What safety precautions should I take when using hand sockets?

1. **Inspect Tools**: Before use, check sockets and ratchets for cracks, wear, or damage. Replace any compromised tools.

2. **Use the Right Size**: Ensure the socket fits the fastener snugly to prevent slipping and rounding off edges.

3. **Secure Attachment**: Confirm that the socket is properly attached to the ratchet or extension to avoid accidental detachment.

4. **Wear Protective Gear**: Use safety glasses to protect eyes from flying debris and gloves to enhance grip and protect hands.

5. **Apply Correct Force**: Use the appropriate amount of force. Avoid using excessive force that can cause the tool to slip or break.

6. **Avoid Cheater Bars**: Do not use pipe extensions on ratchet handles to increase leverage, as this can lead to tool failure.

7. **Work in a Clear Area**: Ensure the workspace is free of clutter to prevent tripping or knocking over tools.

8. **Use Proper Posture**: Maintain a stable stance and keep your body balanced to avoid strain or injury.

9. **Avoid Power Tools**: Do not use hand sockets with power tools unless they are specifically designed for such use.

10. **Store Properly**: Keep sockets organized and stored in a dry place to prevent rust and damage.

11. **Be Aware of Surroundings**: Ensure others are clear of the area to prevent injury from slipping tools or flying debris.

12. **Follow Manufacturer Guidelines**: Adhere to any specific instructions or warnings provided by the tool manufacturer.

13. **Stay Focused**: Pay attention to the task to avoid accidents caused by distraction.

14. **Regular Maintenance**: Clean and lubricate tools regularly to ensure optimal performance and longevity.

How do I use a torque wrench with socket sets?

1. **Select the Right Socket**: Choose the appropriate socket size for the fastener you are working with. Ensure it fits snugly to avoid rounding the fastener.

2. **Attach the Socket**: Connect the selected socket to the square drive of the torque wrench. Ensure it is securely attached.

3. **Set the Torque Value**: Adjust the torque wrench to the desired torque setting. This is usually done by twisting the handle or a dial to align with the specified torque value. Refer to the manufacturer’s instructions for precise adjustment.

4. **Lock the Setting**: If your torque wrench has a locking mechanism, engage it to prevent accidental changes to the torque setting.

5. **Position the Wrench**: Place the socket over the fastener. Ensure the wrench is perpendicular to the fastener to apply torque evenly.

6. **Apply Torque**: Slowly and steadily apply force to the handle of the torque wrench. Continue until you hear a click or feel a release, indicating the set torque has been reached. For beam-type wrenches, watch the scale and stop when the needle aligns with the desired torque value.

7. **Release the Wrench**: Once the torque is achieved, carefully remove the wrench from the fastener. Avoid using the torque wrench to loosen fasteners, as this can affect its calibration.

8. **Store Properly**: After use, reset the torque wrench to its lowest setting to relieve tension on the internal spring. Store it in a protective case to maintain accuracy.

9. **Regular Calibration**: Periodically calibrate the torque wrench to ensure accuracy, especially if used frequently or for critical applications.

What are the benefits of using insulated or nonsparking sockets?

Insulated sockets provide protection against electrical shock by preventing the transmission of electricity from the tool to the user. This is particularly important when working with live electrical circuits or in environments where accidental contact with live wires is possible. The insulation is typically made from materials like rubber or plastic, which are poor conductors of electricity, ensuring user safety.

Non-sparking sockets, on the other hand, are designed to prevent the generation of sparks during use. They are typically made from materials such as brass, bronze, or beryllium copper, which do not produce sparks when struck against other surfaces. This feature is crucial in environments where flammable gases, vapors, or dust are present, as sparks could ignite these substances, leading to fires or explosions.

Both insulated and non-sparking sockets enhance safety in their respective applications. Insulated sockets are ideal for electrical work, reducing the risk of electric shock, while non-sparking sockets are essential in industries like oil and gas, mining, and chemical manufacturing, where explosive atmospheres are a concern. Additionally, using these specialized tools can lead to compliance with safety regulations and standards, potentially reducing liability and insurance costs for businesses.

Overall, the primary benefits of using insulated or non-sparking sockets are enhanced safety, compliance with industry standards, and the prevention of accidents in hazardous environments.