- Home

- Tools

- Power Tools

- Sanding Finishing Tools

.....Read More

Band Files

Belt Sanders

Drum Sanding Machines

Drywall Sanders

Dust Collection Accessories for Sanders

Edgebanders

Floor Sanders & Accessories

Polishing & Buffing Power Tools

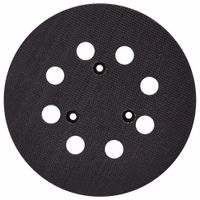

Replacement Backing Pads for Power Sanders

Replacement Parts for Sanding & Finishing Power Tools

Rotary & Random Orbital Disc Sanders

Sheet & Detail Sanders

Spindle Sanding Machines

Wide Belt Sanding Machines

Frequently Asked Questions

What is the difference between a rotary sander and a random orbital sander?

How do I choose the right grit sandpaper for my project?

What safety precautions should I take when using a power sander?

How do I prevent swirl marks when sanding?

What is the best way to collect dust when sanding?

How do I maintain and clean my power sander?

Can I use a power sander on drywall?