- Home

- Tools

- Power Tools

- Rotary Tools Oscillating Tools Cut Out Tools

- Rotary Tools

.....Read More

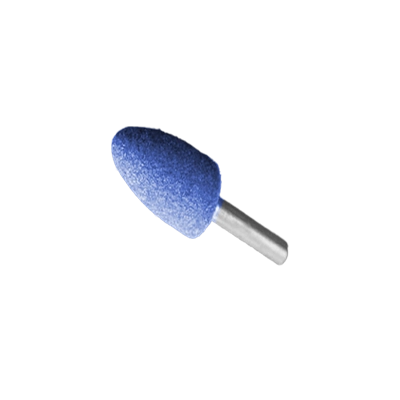

Abrasive Points for Rotary Tools

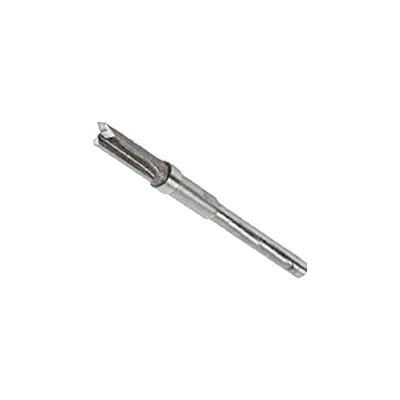

Carving & Engraving Bits for Rotary Tools

Corded Rotary Tools

Cordless Rotary Tools

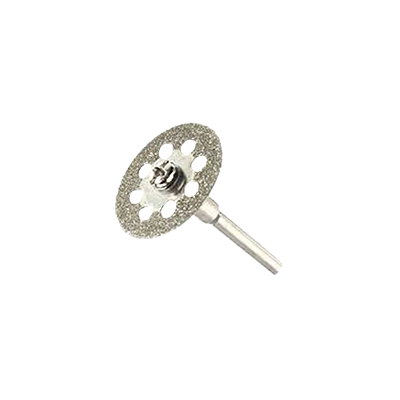

Cutting Wheels for Rotary Tools

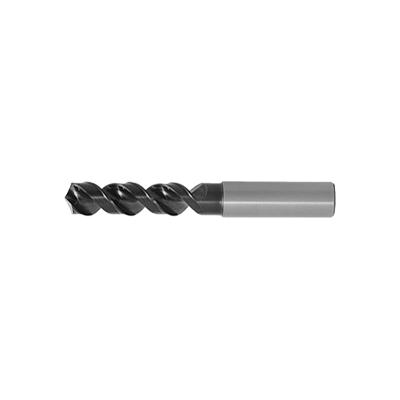

Drill Bits for Rotary Tools

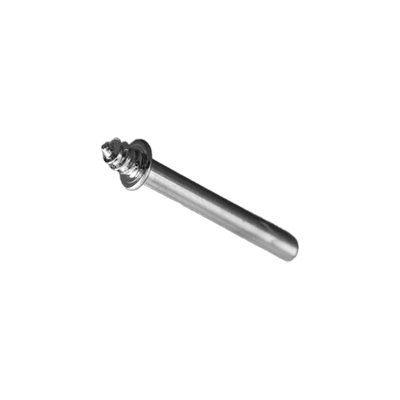

Mandrels, Collets & Chucks for Rotary Tools

Polishing Points & Pads for Rotary Tools

Replacement Parts for Rotary Tools

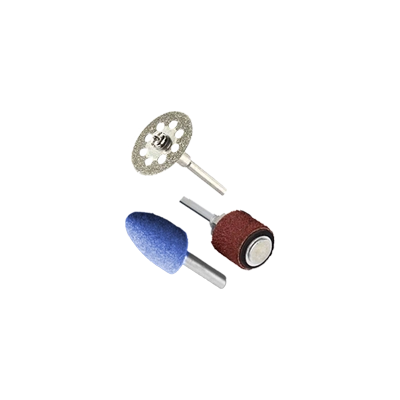

Rotary Tool Accessories

Rotary Tool Bit & Attachment Sets

Routing Bits for Rotary Tools

Sanding Discs & Drums for Rotary Tools

Wire Brushes for Rotary Tools

Frequently Asked Questions

What are rotary tools used for?

How do you change attachments on a rotary tool?

What safety precautions should be taken when using a rotary tool?

What is the difference between corded and cordless rotary tools?

How do you maintain a rotary tool?

What types of attachments are available for rotary tools?

How do you choose the right speed setting for a rotary tool task?